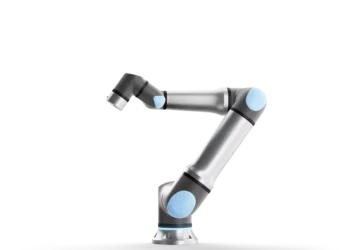

Collaborative robots stand for taking over or supporting employees in boring, time-consuming and repetitive tasks. One of these tasks is manual screwing, a major cause of dissatisfaction on the production floor.

During manual screwing, even your best employees will find themselves in a situation in which they are or become sensitive to missing screws and the over or under-tensioning of these screws. In addition, manual screwing can lead to disruption of the production lines or quality problems and product scrap.

The situations outlined above, with regard to reality, make screwdriving an ideal candidate for automation, especially for collaborative automation.

Unfortunately, until now no application had been developed that could easily be implemented on the robot arm without extensive technical knowledge. As a result, a lot of costly downtime of the cobot was lost and the flexibility with which the collaborative robot is associated was missed.

Meet OnRobot screwdriver

With this screwdriver solution OnRobot has thought completely out-of-the-box. In June 2020 they will launch a plug-and-play screwdriver that enables manufacturers to automate screwdriving processes on the production floor easily, quickly and flexibly. The OnRobot screwdriver is electrostatic discharge (ESD) certified to be safe for electronic assembly.

The uniqueness of this screwdriver is that it has a ‘z-axis’, which means that the robot arm does not have to move when screwing. With the OnRobot screwdriver, the screws are pulled into the reeschap and automatically driven. So no extra programming is required.

The process for attaching this application is simple, compared to traditional screwdriver applications. You insert the screws into the available infeed and then attach the screwdriver to your collaborative robot. The next and final step is to enter the required screw length and torque via an intuitive interface.

The automation of this repetitive task can begin.

The OnRobot screwdriver automatically calculates the speed and force required for accurate screwdriving using the built-in force and torque sensing and linear motion control.

If a screw is subjected to excessive force along its axis, a safety stop will automatically be activated.

By means of the simple programming interface as you are used to from the cobot applications, you can switch to a desired screw size, length or product line in a few minutes.

Manufacturers need simple, easy-to-implement solutions that increase quality on the production feed. The OnRobot screwdriver makes the previously impossible possible.