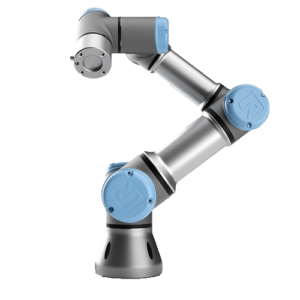

Universal Robots

Universal Robots UR10e

Universal Robots UR10 cobot is an industrial robotic arm designed to perform the toughest tasks with the highest precision. With built-in force/torque sensor, improved precision, much better interface and more, the e-Series Universal Robots UR10e is a worthy upgrade from the original UR10. The robot has a carrying capacity of 10KG.

Payload »

10 KG

Radius »

1300 MM

Weight »

12 KG

Joints »

6 DOF

UR10e - Large, strong and accurate

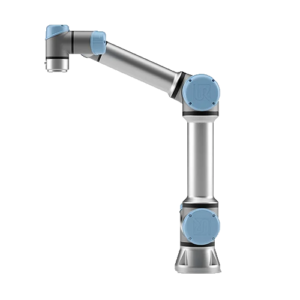

The Universal Robots UR10e is the middle cobot in the UR series. With a load capacity of 10 kg and a range of 1300 mm, this collaborative robot is made for heavier, more robust tasks. The perfect choice for tasks such as packaging, palletising, assembly and pick-and-place work. Despite its size, this robot is extremely precise. With an accuracy of about 0.1 mm, the robot is suitable for the most delicate tasks. The Universal Robots UR10e is an extremely versatile collaborative industrial robot arm with its high payload (10kg) and long reach capability. Its 1300mm reach spans wide workspaces without compromising precision or payload performance.

Like all other cobots in the UR range, the UR10e is very easy to set up and program. This robot also has the possibility to manually set movements in the software, after which they can be perfected on the touchscreen tablet. It is also possible to work together with this robot, without the use of safety screens.

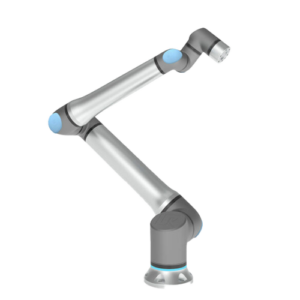

The robots of Universal Robots.

Universal Robots started with the introduction of cobots in 2009 and has now introduced three variants to the market: the UR3, UR5 and UR10. These cobots are characterized by their flexibility, light weight and user-friendliness and have 6 separate joints. They are perfect for mid-size companies that need flexible, effective automation with a fast return on investment. Thanks to their light weight, they are easy to move around and do not require a robust surface.

The cobots are supplied with attributes that make it possible to program them, such as a controller box, a touch screen and software. The graphical interface makes programming easy and accessible for everyone. In addition, according to the applicable rules, they can be operational without shielding and can be placed in a shared workspace with employees.

Assembly

Packing

Testing

Bin picking