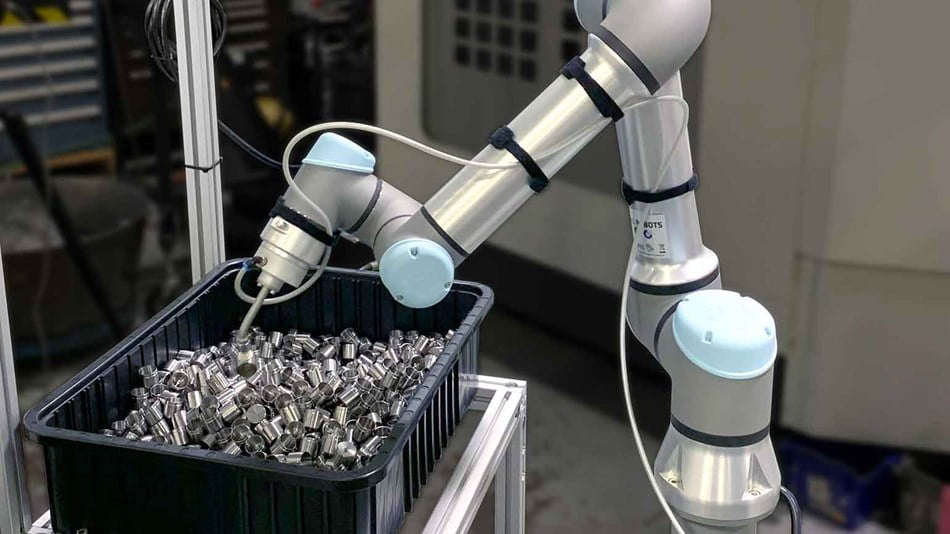

Bin picking with a collaborative robot

Bin picking is a pick-and-place application with vision technology. Two of the most advanced modern automation technologies meet here; robots and computer vision. This creates new automation opportunities. Thanks to 3D vision, robots are able to recognize and pick up products in a bin. This means that parts and products no longer need to be presented to the robot in a standardized way. The robot distinguishes products and thus picks them up one by one. Bin picking changes the way we look at a robot's capabilities. Previously, the supply and repeatability of a task was very important. Whereas a cobot first had to receive a standardized supply of products from a conveyor belt, the robot can now load this conveyor belt itself after the products have been delivered in bulk.

Cobot bin picking video

Watch the video below in which a cobot performs a bin picking application using vision.

Cobot bin picking benefits

Saving of costs

You will save on personnel costs

Increasing productivity

Staff can do other work

Utilize full capacity

Get more out of your employees

Prevent disorders

Prevent disorders among employees

No loss of concentration

Robots will never lose concentration

Constant quality of output

Robots deliver consitent quality

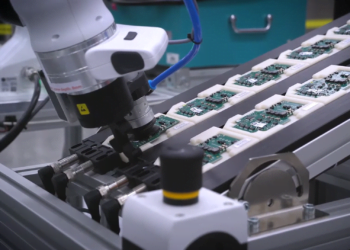

Vision increases the opportunities

Thanks to vision, smart software, machine learning and artificial intelligence, the possibilities of bin picking become much greater. Software is becoming more sophisticated, making it possible to recognize colors, shapes and sizes as well. It is therefore possible to offer the robot a bin of objects, which can then be sorted by characteristic. Cobots are characterized by their user-friendliness, so a bin picking application is set up in no time.