Machine tending with collaborative robots

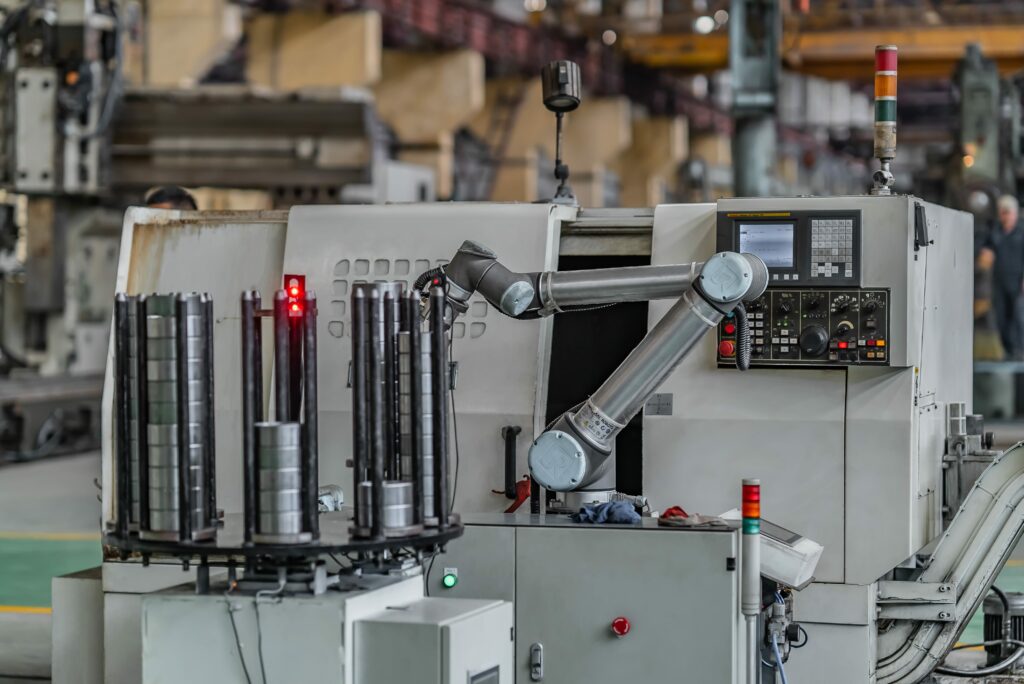

Machine tending is the loading and unloading of a particular machine with parts and materials. Currently, many of these tasks are still performed by humans. CNC machines, such as milling machines and lathes, are mostly still operated by operators. They maintain the machines and place the raw parts and take out the machined parts. Since it is becoming increasingly difficult to find suitable employees for this, this task can be perfectly automated with a cobot. Thanks to communication between the robot and the machine, the robot knows when to load and unload. As long as the supply of raw parts remains on, the cobot can keep up this work 24 hours a day.

Cobot machine tending benefits

-

Saving of costs

You will save on personnel costs

-

Increasing productivity

Staff can do other work

-

Utilize full capacity

Get more out of your employees

-

Prevent disorders

Prevent disorders among employees

-

No loss of concentration

Robots will never lose concentration

-

Constant quality of output

Robots deliver consitent quality

More productive and less dangerous

As mentioned, machine tending is normally performed by people. An operator loads parts into a machine. The machine does its job, after which the worker removes the finished product and places a new part. A repetitive task that takes up a lot of time. Time that could be used more productively. In addition, there is a risk of injury. Over time, concentration decreases with such a repetitive task, increasing the chance of error and injury. A robot will always perform this work in the same way, without losing concentration. By allowing workers to focus on more complex tasks, workers are challenged and happier in the work they do.

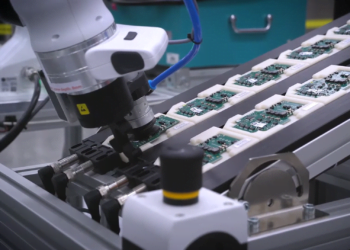

Cobot machine tending video

Watch the video below in which a cobot performs a machine tending application.