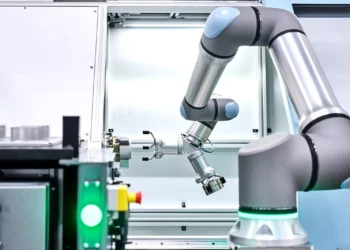

As an automation company, automation is important to us. Logical. Hopefully we don't have to convince you of the importance of robotization and the advantages of cobots. You can read enough about this on our blog page. But maybe you have to convince someone else to use cobots. To give you a helping hand, we have listed 5 common arguments for not automating, with a convincing response.

1. 'It is too expensive'

Automation does indeed mean that an investment has to be made. But the whole idea of automation is that it will make money. By automating, you increase productivity, reduce the chance of mistakes and you will ultimately achieve the maximum with minimal costs. In the long run, you will therefore earn back the investment more than once. In addition, robotization is no longer as expensive as it was a few years ago. Compared to traditional industrial robots, cobots are a cheap alternative and accessible to everyone.

2. 'It shall take the place of staff'

The arrival of a robot is often a reason to fear reorganisations and dismissed employees. Automation of a robot brings about exactly the opposite. A cobot is a robot that works together with people. It is not there to replace staff but to help them. The cobot will spare people from dangerous, repetitive work, allowing them to focus on something they are really good at. The cobot enables people to develop themselves. An improvement of happiness at work instead of lack of work.

3. 'Things have been going well for years'

The fact that things have been going well for a long time is no reason to choose not to innovate. In recent years, technological developments have been so drastic that the sector has changed. Smart Industry for example has the ambition to have the best digitally connected production network in the Netherlands. If you ignore these kinds of developments, you will eventually lose your competitive position.

4. 'We do not have the right knowledge at hand'

In the past, robots used to require a lot of expertise. If a robot didn't work or it had to be reprogrammed, experts had to join in to solve it. Often this also took a lot of time. This does not the same for cobots. With user-friendly software, it is possible for anyone to teach the robot new tasks and this can even be done in no time.

5. 'There will be a lot of resistance from the company'

Despite all these good arguments, there is a good chance that resistance will arise as soon as you start with automation. We already wrote a blog about how to guide employees with innovations but the most important thing is just to do it. Give everyone time and space to get used to it and over time you will see that it produces a positive result.

Contact WiredWorkers and get to know our cobots, and discover all the unique features of this advanced new technology.