Implementing collaborative robots (cobots) in a manufacturing process can be a smart move to increase efficiency, productivity and competitive advantage. But, before manufacturing companies take the plunge and invest in cobots, there are several important considerations that need to be made to ensure that the right choice is made. In this blog, we will discuss some of these crucial considerations.

1. Applications

It is essential to start with a clear understanding of the specific applications that a cobot needs to do. What tasks do you want to automate? What level of flexibility is required? What does the production process look like? Answering these questions helps identify the right cobot configuration, such as the type of robotic arm, payload capacity and end-effectors needed.

2. Safety requirements

Safety is key when working with collaborative robots, as they operate side by side with human operators. Make sure the selected cobot meets relevant safety standards and has built-in safety features such as sensors to prevent collisions and make speed adjustments in the presence of humans.

3. Programmability

Take a look at the cobot's programming system. Is it intuitive and user-friendly? Can it be programmed offline to minimise downtime? The ability to programme the cobot quickly and easily is crucial for smooth implementation and adaptation to changing production needs.

4. Costs and ROI

Make a thorough cost-benefit analysis before making a purchase decision. Besides the initial purchase price, take into account the cost of training, maintenance and any modifications to the production line. Calculate the expected ROI (return on investment) to assess how quickly the investment will pay for itself.

5. Support and training

Check that the manufacturer or supplier provides adequate training and technical support. Training staff to work with cobots is essential for successful implementation. Ensure there is access to help when needed to resolve any technical issues.

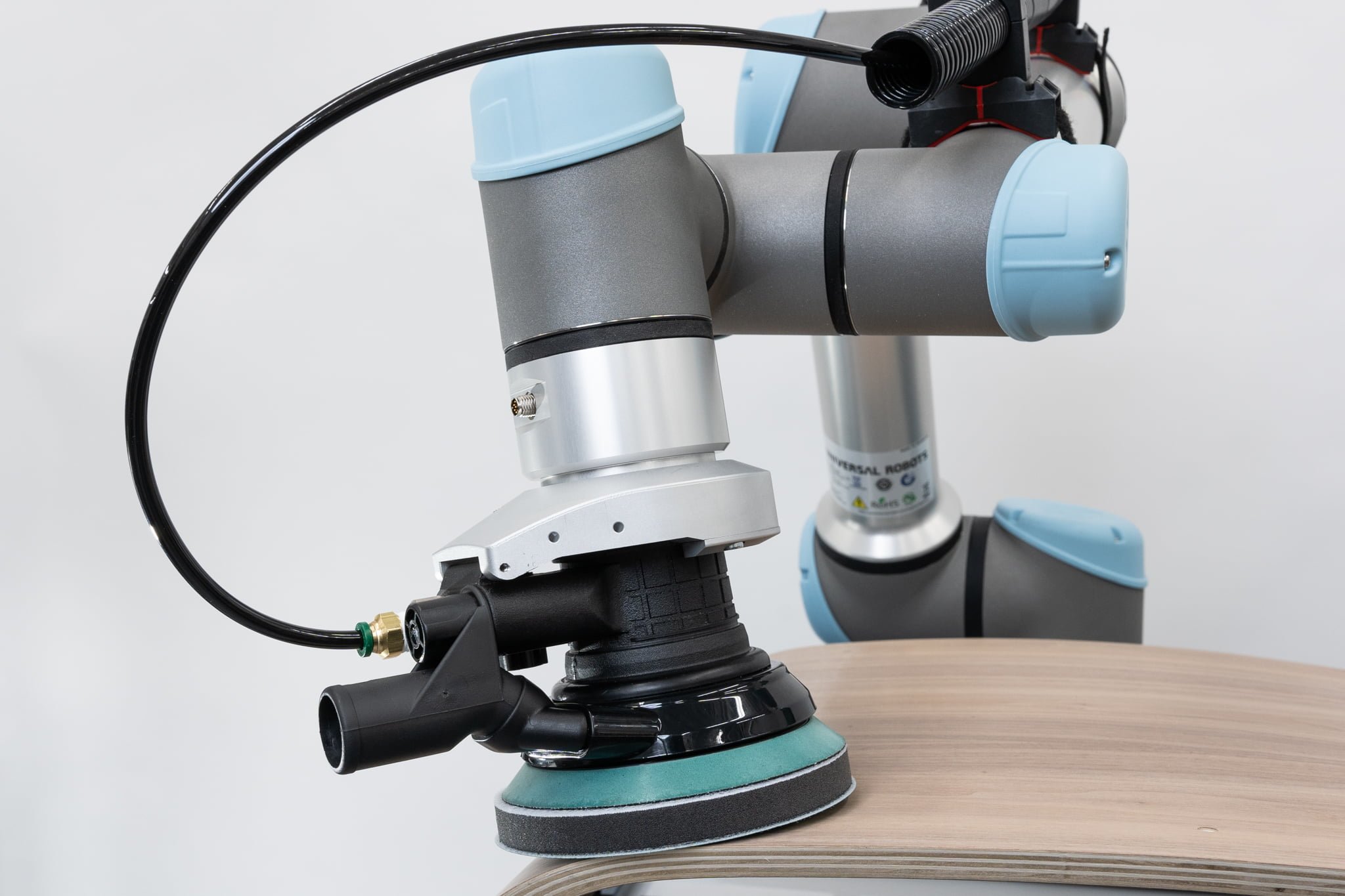

6. Integration with existing systems

Modern cobots are equipped with advanced vision systems and sensors that can detect and identify objects. This enables them to adapt tasks based on the objects they work with, making them highly versatile.

7. Scalability

Think about the future. Is the cobot configuration scalable for future needs? It is possible to add additional cobots or adapt the existing configuration as companies grow and change.

8. Reliability and sustainability

Look at the reliability and durability of the cobot. How long is the system expected to last? A reliable cobot will save costs and downtime in the long run.

9. Regulatory and compliance considerations

During implementation, ensure that those responsible are aware of the regulations and standards applicable to the use of collaborative robots. And, of course, ensure that the chosen cobot meets all these requirements.

10. Case studies and references

Before purchasing, it is advisable to consult case studies and view references from companies that have already implemented collaborative robots. This can provide insight into the experiences of others and help make an informed decision. WiredWorkers has already implemented several cobot setups. These can all be seen at business cases.

Getting to work!

In short, purchasing collaborative robots is an important investment that requires attention and careful planning. By keeping these important considerations in mind, you can make the right cobot selection and optimise your production process for greater efficiency, productivity and long-term success. Collaborative robots undoubtedly offer opportunities, but only if implemented strategically and thoughtfully. WiredWorkers is an expert in the field of automation and has already helped several companies implement collaborative robots. Contact us or schedule a free cobot consultation!