When we talk about robotization, we quickly make the connection with manufacturing companies in various sectors. Think of the metal, electronics, automotive and food processing industries. Tasks such as pick-and-place, welding, gluing, screwing or palletizing are often the first applications that come to mind. Nevertheless, the growth of robotics in the pharmaceutical industry is currently greater than in any other industry. Why is robotics so suitable for the pharmaceutical industry and with what applications can robots be of value?

Benefits of robotization

Before we move on to the applications of robots in pharmacy, let's look at the benefits that automation brings.

Increased productivity

Robots can significantly increase production by performing certain tasks better and faster.

Consistency

Robots always perform tasks in exactly the same way which also improves the consistency of the products.

Reduction of downtime

Compared to an employee, a robot can run 24 hours a day and does not need to take breaks.

Increased flexibility

Robots, especially cobots, are very easy to program. This makes it possible to have them perform different tasks in a short period of time and respond quickly to changes.

Faster market introduction

Robots can help within the pharmaceutical industry to do tests and trials, allowing the R&D department to do its job faster. Thus, new products can be introduced to the market faster.

Where to start?

As a company, it is important to look at the benefits that will have the most impact on the bottom line. Which processes within the company would benefit the most from the above benefits? These are good indicators that these processes would benefit greatly from automation.

It is also useful to look at which tasks lead to the most return on investment without having to make too many internal changes. These are suitable tasks to automate first. After this has proven successful, you can look further into other processes that can be automated.

Robot applications for pharmaceutical companies

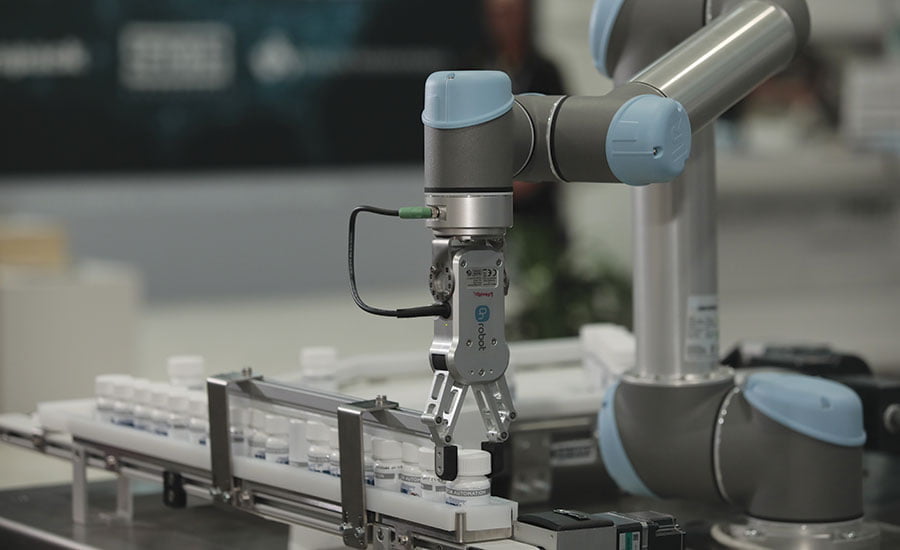

Pick-and-place

Pick-and-place is simply the picking up and moving of items. This can be products that need to be picked off a conveyor belt and into a work area or sorting items for further processing. For the pharmaceutical industry, you might think of sorting medicine bottles or arranging syringes.

Inspection

Inspection is a tough job for workers because they must be high in concentration throughout their work. A mistake in inspection can have fatal consequences for pharmacists. Robots can be a godsend here because they can work with extreme consistency. For example, robots can check that blister packs are completely filled or detect defects. A Techman Robot is well suited for this thanks to its built-in vision system.

Closing bottles

The closing of (medicine) bottles is perfect to automate. For employees, tightening caps is a monotonous, mind-numbing task. Robots, on the other hand, can easily keep it up all day with precision and consistency. With the right robot, end effector and sensors, sealing bottles with a robot can make for a faster and more consistent process.

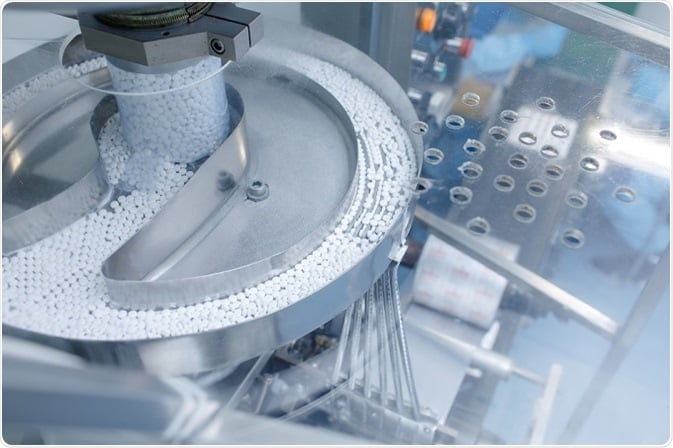

Dosing

Dosing is a task that by no means always conjures up associations with robotization. Yet it is an application that is already frequently performed by robots, for example in the form of gluing. By attaching a dispensing machine to the robot, a robot could fill medicine bottles or syringes, for example.

Machine tending

Within the pharmaceutical industry, semi-autonomous machines are widely used. Normally these are loaded and unloaded by an employee. However, it is also possible to have this task done by a robot. This allows the worker to engage in tasks that add more value. An example of such a task is feeding samples into a testing machine.

Packing

Packing products is an important task in every sector, including pharmaceuticals. Examples of tasks that a robot could automate are packing drugs in pouches or boxes, loading products on trays or stacking boxes on pallets.

Clearly, there are several options for implementing automation through robots within the pharmaceutical industry. Moreover, there are even more options in addition to the applications described above. It is important to look carefully at which tools, software and robot are suitable for this.

Get to work!

WiredWorkers specializes in automation and can help make the right choices. We strive to create a world where the qualities of workers are fully utilized, so we are happy to help make implementing robotic applications as successful as possible. Would you like more information? Are you curious about how a robot can be used as effectively as possible in your company? Then contact us or register for a free cobot consultation.

Frequently asked questions

What are the benefits of introducing robotics into the pharmaceutical industry?

Robotics in the pharmaceutical industry offers numerous benefits, including increased productivity, consistency in tasks, reduction of downtime, enhanced flexibility, and faster market introduction. Robots can significantly boost production by performing tasks more efficiently and reliably than humans, leading to improved product consistency and increased operational hours.