In the rapidly changing manufacturing sector, robots are playing an increasingly prominent role. Robotics are becoming increasingly sophisticated, meaning they are not only programmed to perform repetitive tasks, but also to learn and adapt to changes in their environment. We call this adaptive robotics. In this blog, we take a closer look at adaptive robotics technology and its impact on the manufacturing sector.

What is adaptive robotics?

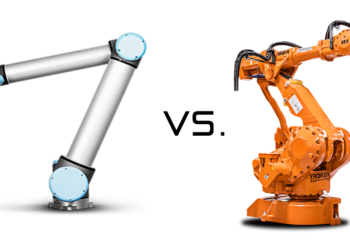

Traditional industrial robots are programmed to perform specific tasks in a static and predictable environment. They are often separated from human workers by physical barriers and perform repetitive tasks with a high degree of accuracy and precision. While they are efficient at performing these tasks, they often lack the flexibility to adapt to changes in the production environment.

With adaptive robotics, this is different. Adaptive robots are equipped with advanced sensors, actuators and AI algorithms that enable them to learn from their environment and adapt to changing conditions. Instead of performing rigidly programmed tasks, adaptive robots can adjust their behaviour based on new information and feedback from their environment.

Applications in flexible production environments

One of the main applications of adaptive robotics is in flexible manufacturing environments where product demand is constantly changing. Instead of reprogramming robots every time production needs to be adjusted, adaptive robots can be self-learning and automatically adapt to new production requirements. This reduces the need for human intervention and increases production line productivity and efficiency.

An example is an assembly robot that has the ability to adjust its speed and precision to fluctuating production conditions, thus optimising the efficiency and quality of the production process.

Cooperation with human workers

Another important aspect of adaptive robotics is its ability to work with human workers in a safe and collaborative manner. Adaptive robots can be equipped with advanced sensors that enable them to detect and respond to human movements and behaviours. This opens up new opportunities for human-robot collaboration in manufacturing, with robots and humans working side by side to perform tasks that were previously too dangerous or complex for humans alone or robots alone.

Challenges and ethical considerations

One of the challenges of adaptive robotics is developing advanced AI algorithms capable of making complex decisions in real-time. This requires a deep understanding of both robotics and the specific manufacturing processes in which the robots are deployed. There are also ethical considerations regarding the impact of adaptive robotics on employment and human dignity that need to be addressed.

Getting started!

Adaptive robotics will play an increasingly important role in the manufacturing sector. Where robots are no longer just programmed to perform tasks, but also to learn and adapt to changing conditions. This technology has the potential to improve the productivity, efficiency and safety of production processes and open up new opportunities for human-robot collaboration.

WiredWorkers, an expert in automation, has already helped numerous companies implement robots. Contact us today or schedule a no-obligation online consultation!