7 advantages of using

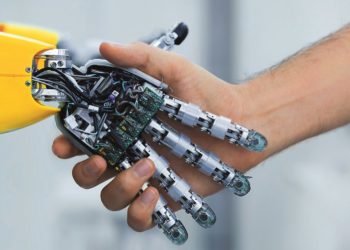

In recent years, productivity within the manufacturing industry has been steadily increasing. One way to increase productivity is to use cobots. Cobots, or collaborative robots, are robots that work with people in a shared workspace. Therefore, in this blog, 7 advantages of cobots and automating processes.

1. Fast installation

Normally, installing a robot takes a few days (or maybe even weeks) before it is up and running. Installing a cobot, on the other hand, can be completed within half an hour and with the user-friendly software, a cobot could perform its first task within an hour. This makes a cobot available as a temporary employee or flexible employee who can perform different tasks in different departments.

2. Quickly programmed

Traditional robots require a lot of knowledge and time to program actions and can often perform just one action. Unlike the traditional robots currently used in industry, a cobot is easy to program. By means of user-friendly software and mobile applications, cobots can learn new actions. You can also manually set a cobot to the desired positions and save them in the software. Because a cobot is so easy to program, it can be quickly implemented in a process and it is even possible to have it perform different tasks.

'During peak times it is more practical to hire a cobot for a short period of time than to hire an employee'

3. Can be used in different departments.

It has already been briefly mentioned above. A cobot is a flexible robot and adding new tasks to the robot is quite simple. A cobot could do the same for a 40 hour working week, but could also perform a different task every day. For example, it is possible to look per day for places within the production process where the robot can be of value. This flexibility also makes it possible to hire a cobot as a temporary employee. For example, during peak times in production, it is more practical to hire a robot for two weeks than to hire an employee for two weeks.

4. More consistent and accurate than humans.

Unlike humans, cobots are very accurate. The Franka Emika Panda for example; this cobot can perform actions with an accuracy of 0.1 mm. In addition, a cobot will never deviate from its actions and will always perform tasks with the same power. For example, tightening screws, this will always be done with the same tension and pressure which ensures consistency in quality.

5. Positive effect on employees.

A cobot is designed to work with people and not to replace people. Cobots are also called people-focused robots and can help people to make and refine the work they do easier. Dirty, unsafe, boring, monotonous or repetitive tasks can be performed by the robot so that employees can concentrate on other tasks. Think of quality checks and maintenance, but also the assembly of a product could take place in cooperation with a cobot. For example, the cobot is screwing a product, so that the employee completes the product one step further in the process.

'Because employees are supported in the tasks they perform, they will enjoy the work they do more'

6. Employees become happier in their work.

Because employees are supported in the work they do, they will enjoy the work they do more. The boring, monotonous work will be outsourced to the robot so that employees will do their work more 'humanely'. Tasks where creativity, solution-oriented thinking and initiative are given more space. In this sense, robots contribute to an attractive working environment. Not to mention the prevention of RSI, a condition that occurs when the same operation is performed for a long time. In the long term, this means less absenteeism, more involvement of employees, an enrichment of the work, a high level of job satisfaction and a contribution to the personal development of employees.

7. Increased productivity and process optimization.

The main goal of robotization is of course to optimize a process. In other words, achieving the maximum goal with minimal costs. Errors are minimized, employees have more time for other things, productivity increases and ultimately this results in a better operating result. Setting up and equipping a cobot obviously requires an investment, but in the long run it saves money and even results in a profit.

For more information about automation of processes by means of cobots, please contact WiredWorkers or sign up for a free online cobot demo.

Frequently asked questions

How safe are cobots to work alongside humans?

Cobots are specifically designed to work safely with humans in a shared workspace. They are equipped with advanced sensors and safety features to prevent any accidents. These features include force-limiting technology, hand guiding, and speed and separation monitoring. If a cobot comes into contact with a person, it will immediately stop moving. Additionally, many cobots are designed with rounded edges and soft materials to minimize the risk of injury.