The technological train keeps moving forward, and innovations in automation are emerging at a rapid pace. The buzzword of 2024 was AI, but human-robot collaboration is also taking on an increasingly significant role in the manufacturing world. In 2025, evolving business needs and technological advancements will further transform the way we produce and work. This blog highlights the automation trends we can expect to see in 2025.

1. Plug & Produce solutions

Plug & Produce solutions are becoming increasingly popular due to their easy implementation and immediate impact. These standardised automation solutions offer companies a quick way to optimise processes without lengthy integration processes. Take Palletizers, for example, which can be deployed directly in production environments with minimal configuration. This significantly lowers the entry threshold for automation, especially for small and medium-sized companies. The benefits? Fast ROI, scalability and flexibility to respond to changing production requirements. By 2025, more companies will switch to these turnkey systems to stay ahead of the competition.

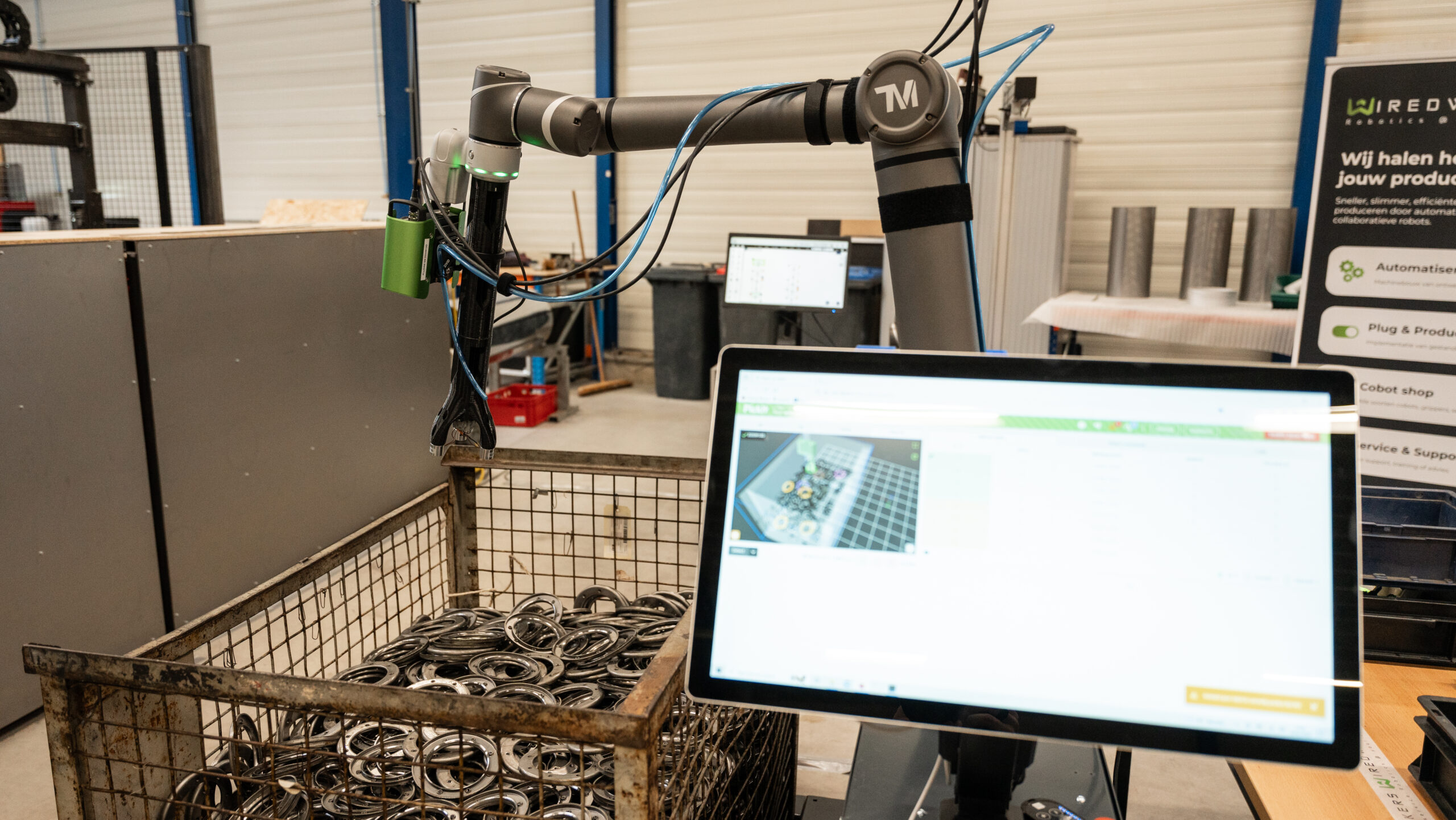

2. Human-cobot collaboration

Cooperation between humans and cobots is becoming more advanced than ever. Improved sensors and software allow cobots to work even more safely and accurately alongside humans. This trend makes it possible to automate complex tasks without employees having to worry about safety. In addition, cobots take over routine tasks, allowing employees to focus on more strategic work. As a result, companies benefit from increased productivity and employee satisfaction.

3. Food-grade cobots

Food-grade cobots are specially designed to meet the strict hygiene and safety standards of the food industry.

Manufacturers such as Doosan Robotics offer models with NSF Food Zone certifications and IP ratings such as IP66, meaning they can withstand dust and powerful water jets, and are suitable for use in wet and hygienically critical environments. Techman will introduce new food-grade cobots in their S series in the second quarter of 2025, certified for the NSF Splash Zone and with an IP65 rating, indicating protection against dust and water jets. FANUC has developed food-grade variants of their CRX series, which feature food-grade grease and an IP67 rating, meaning they are fully dust-proof and water-resistant, and suitable for use in food production environments.

These cobots are a valuable addition to modern food processing facilities because of their precision, consistency and ability to work safely alongside human workers.

4. Smart data integration

Data remains the backbone of automation. In 2025, companies will bet on integrated data platforms that break silos and provide real-time insights. By combining data from sensors, machines and business software, companies can make better decisions. This makes it possible to align production processes even more tightly with demand forecasts and market changes. Smart data integration also helps companies reduce waste and improve sustainability.

5. Vision and AI for quality control

Vision technology combined with machine learning and AI will make a huge leap in 2025. These technologies will become increasingly accessible as AI models can be trained faster with smaller data sets. This drastically reduces the cost of quality control. Vision-based systems can scan products in real-time, detect defects and optimise production processes. Think of inspecting packaging, checking food safety or ensuring uniformity in industrial products. This trend enables companies to produce more efficiently and accurately, while reducing waste.

6. Augmented Reality (AR) for support

AR will be an important tool in automated environments by 2025. AR will allow workers to get real-time support while operating machines or performing maintenance. For example, through smart glasses that show step-by-step instructions. This speeds up the learning process and increases the accuracy of tasks. AR not only improves efficiency, but also ensures better cooperation between humans and machines.

7. Flexible production

Flexibility will be a must in 2025. Consumers increasingly demand personalised products, putting pressure on traditional mass production. Automated systems that can quickly switch between production lines and product variants will become crucial. Modular production systems and cobots play a major role in this. Companies that can produce flexibly remain competitive in a rapidly changing market.

8. Focus on safety

In 2027, the new European Machinery Regulation (Regulation (EU) 2023/1230) will come into force, which will replace the current Machinery Directive 2006/42/EC. Key changes include stricter requirements for risk assessment, mandatory use of cybersecurity measures in software-controlled machinery and more detailed documentation of technical specifications. Companies are already anticipating these changes by future-proofing their processes and equipment. Automation solutions that comply with these new standards not only provide a competitive advantage, but also minimise legal and operational risks.

9. Humanoids in manufacturing environments

By 2025, the first humanoid robots, such as Tesla's Optimus and Figure's AI-powered humanoids, will be deployed on a small scale in manufacturing environments. These robots take automation to the next level by replicating human tasks in physical environments. Humanoids combine advanced mechanics with embodied AI, enabling them to adapt to complex situations, navigate independently and even collaborate with human colleagues. Applications range from assembly and logistics to performing repetitive operations in environments less suitable for humans. Although currently in limited use, their introduction in industry will foreshadow wider adoption in the future.

10. Embodied AI and self-aware machines

2025 could well be the year when embodied AI - artificial intelligence integrated into physical systems - makes its appearance. This technology not only gives robots a body, but also a form of awareness of their surroundings and actions. Think AI systems that coordinate movements and interactions with humans as if they were intuitive. This opens up opportunities for advanced applications in manufacturing, healthcare and logistics. Innovations such as these are enhanced by contributions from companies such as NVIDIA, which are focusing on AI systems that learn and adapt within physical environments. Embodied AI lays the foundation for a new generation of machines that not only act, but also understand.

Conclusion

The automation trends of 2025 mark an exciting period of innovation and progress. From plug-and-produce systems and vision technology to the introduction of humanoids and embodied AI, the possibilities seem endless. Companies that embrace these trends will not only produce more efficiently, flexibly and sustainably, but also gain a competitive advantage in an increasingly competitive market. At the same time, the new European Machinery Regulation emphasises the importance of safety and technology integration, paving the way for a future where humans and machines work together seamlessly. The coming years present opportunities for companies ready to innovate and invest in the future of automation.

WiredWorkers is an expert in the field of automation and has already helped several companies implement collaborative robots. Contact us or schedule a free cobot consultation!