Manufacturing companies understand better than anyone how important it is to ensure that the production process is as controlled as possible. Besides the fact that an uncontrolled production process leads to costly downtime, it can also occur that end products do not meet up to the standards. An important factor that contributes to standardization is dosage, the continuous use of the same amount of material. A great product that can contribute to this is the cobot dispenser.

What is a cobot dispenser?

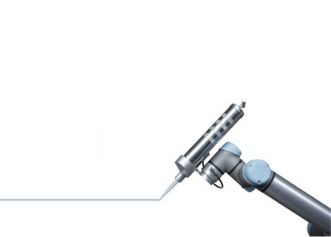

Before we go deeper into the application possibilities and benefits, it is good to explain exactly what a cobot dispenser is. Cobot dispensers are a form of end-of-arm tooling that dispense liquid substances in a uniform manner. In practice, dispensers are most commonly used for gluing and sealing.

Why it's better than manual dosing

There are a number of reasons why a cobot dispenser is more suitable than a human hand. First, dispensing within a manufacturing process is generally a monotonous, repetitive task. For an employee, this is not challenging and it requires little creativity. By having a cobot do this type of work, employees can focus on more challenging tasks. This has a major impact on personal motivation and commitment to the process.

It is not only the positive effect on employees that is a benefit. It also contributes to the quality of the product. Cobot dispensers, unlike humans, will always use exactly the same amount of material in exactly the same way. If a cobot is used to glue parts together, exactly the same amount of glue will always be used. This means that the bonding strength is the same for every product and no glue is wasted. The risk of errors, waste and the associated costs are reduced to a minimum.

Other benefits

In addition to the advantages over humans, cobot dispensers have several other advantages. For example, cobot dispensers are operated electrically. This means that the liquid is squeezed out of the dispenser. Unlike pneumatic operation, this has a major advantage. Pneumatics are highly dependent on viscosity and temperature of the liquid and this can be a problem if you depend on consistent volumes. The electric dispenser is not affected by viscosity and temperature, so the dispensers dispense liquids with high repeatability.

Furthermore, it is a lot more practical to work with an electric dispenser. Like the dispenser, the cobot also runs on electricity. So it's already there. If you were to work with pneumatic dispensers, air lines would have to be laid.

Applications of cobot dispenser

As mentioned, dispensers are most commonly used for gluing and kitting parts. WiredWorkes uses dispensers from AIM Robotics for this purpose. This company from Denmark provides accessible, user-friendly and versatile dispensers for small-scale manufacturers. They do this with Plug&Play solutions that are easy to mount on all collaborative robots. The dispensing units are designed to integrate seamlessly with cobots and meet all safety standards. Watch the video to see what possibilities AIM's dispensing units offer.