Developments in (collaborative) gripper capabilities.

One of the most striking advances in cobot technology can be seen in gripping and manipulation systems. Traditional industrial robots were often limited to performing repetitive tasks in a controlled environment, but cobots go beyond these limitations. They are designed to work safely with humans and to flexibly handle a variety of tasks.

Adaptive grippers

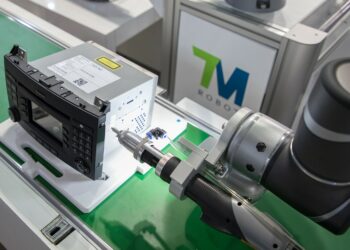

An important innovation in this area is the development of adaptive grippers. These grippers can adapt to different shapes and sizes of objects without prior programming. This means that cobots are now able to handle a wide range of objects, from fine electronic components to heavy industrial parts. These adaptive grippers significantly increase the versatility of cobots and allow them to quickly change tasks without extensive reprogramming.

Integration of AI

Another notable innovation is the integration of artificial intelligence (AI) into the grasping process of cobots. By applying AI algorithms, cobots can recognize, understand and react to objects in a way that was not possible before. This enables cobots to perform more complex tasks, such as sorting objects based on different criteria or handling objects with variable shapes and materials.

Advanced sensor technology

In addition to adaptive grippers and artificial intelligence, cobots also benefit from advanced sensor technologies. Tactile sensors allow cobots to measure the force applied during gripping, allowing them to adjust their grip to the requirements of a specific task. Visual sensors enable cobots to recognize objects and understand their position in the environment, which is crucial for accurate manipulation.

These technological advances have led to wider acceptance of cobots in various industries. In manufacturing, cobots are now being used for tasks such as assembling components, packaging products and handling materials. In warehouses and logistics, cobots help pick and place goods, improving efficiency.

Conclusion

In conclusion, innovations in gripping and manipulation capabilities of cobots have paved the way for a revolution in the way we deploy robots in various industries. From adaptive grippers to artificial intelligence and advanced sensor technologies, these advances increase the flexibility, efficiency and safety of cobots. As we move into the future, cobots will undoubtedly continue to evolve, creating new opportunities for human-machine collaboration.

WiredWorkers is an expert in the field of automation and has already helped several companies implement collaborative robots. Contact us or schedule a free cobot consultation!