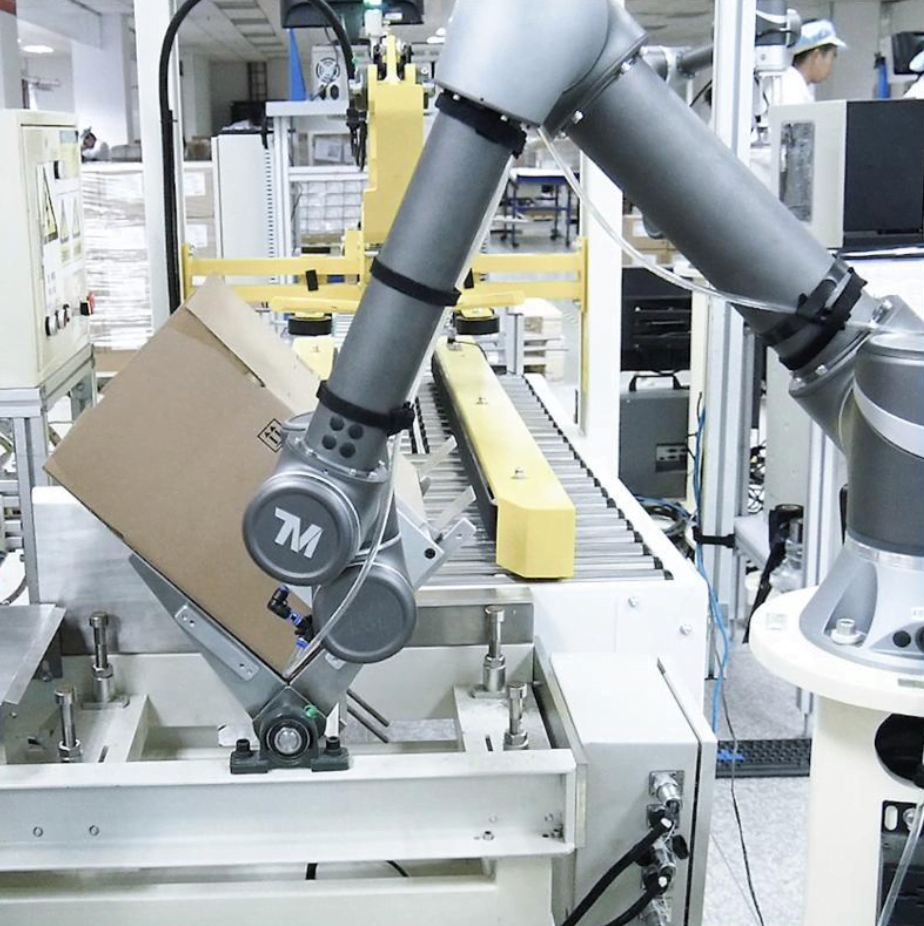

Palletizing is one of the most popular tasks to automate with a collaborative robot. This is not surprising, either. Almost every factory and warehouse involves some form of shipping and receiving goods, where pallets come and go on a regular basis. In addition, the task is ideal for automation. It is repetitive, tedious and physically demanding work that is stressful for workers while relatively easy for robots. Yet it is not always easy to implement such an application, and there are also differences between palletizing and depalletizing. Which ones those are you can read in this blog!

What is the difference between palletizing and depalletizing?

Palletizing is loading materials onto a pallet. Depalletizing is unloading goods from a pallet onto a production line. You probably already knew that. That one is typical of goods shipping and the other is typical of goods receiving you probably knew that too. It may seem like one operation is the same as the other, just in reverse. Yet there are unique challenges for both applications.

Important factors of palletizing

When designing a palletizing solution, there are three main factors to consider. Namely; material, setup and speed (cycle time).

Material

The material or object to be handled is always one of the first things to think about when implementing a palletizing solution. Should the robot handle boxes, crates or bags? What are the dimensions? Are they easily distinguishable by sensors? Are there certain QR or bar codes that need to be scanned. Based on these questions, you can determine which robot, gripper and (vision) sensors are needed.

Arrangement

The way objects arrive via the incoming conveyor and the way they are to be placed has a major impact on the design. Is there a specific placement plan? Do slipsheets need to be placed between loads? Do products arrive on the conveyor one-by-one or in bulk? The answers to these questions affect the gripper selection and setup of the palletizing solution.

Speed

Cycle time is an important element when it comes to automation, but in palletizing it is even more important because it is the end station of the production line. A problem at the palletizing station can cause problems at an earlier stage of the production line. For example, jams can occur if the supply of products is too fast and the robot cannot clear them in time.

Important factors in depalletizing

As mentioned, depalletizing is like rewinding a palletizing task. Yet there are some unique challenges to depalletizing that are not relevant to palletizing. For example, while speed is important, material and arrangement are much more important.

As with palletizing, the objects to be handled have great influence on the robot, gripper and sensor choice for depalletizing. But what adds additional complexity is how these materials are delivered. This is because when depalletizing, this is an external factor because the pallet is loaded by someone else. Thus, there is always a chance that the objects are stacked illogically or inconsistently, making the process of depalletizing more complicated. There is also the possibility that the boxes are placed too close together, making gripping more difficult. In this scenario, vision sensors may also detect two boxes as one.

It may also happen that there are several objects on one pallet. Should it be the case that these objects should not all be placed in the same place, it will be necessary to work with recognition. For example, a barcode scanner so that the robot can recognize where the product should be placed. In addition, the size of the object is also decisive. If the size of the objects differs, it will be necessary to look carefully at how this can be managed with recognition and gripper selection.

Getting started!

So, to automate a palletizing or depalletizing task, several factors must be taken into account. The good news is that there are several systems and tools available that provide solutions to these challenges and are often proven results in practice.

WiredWorkers is an expert in the field of automated palletizing and has already helped several companies implement a palletizing solution. Curious about the possibilities? Contact us or schedule a free cobot consultation!

Frequently asked questions

The three main factors to consider when designing a palletizing solution are material, arrangement, and speed (cycle time).