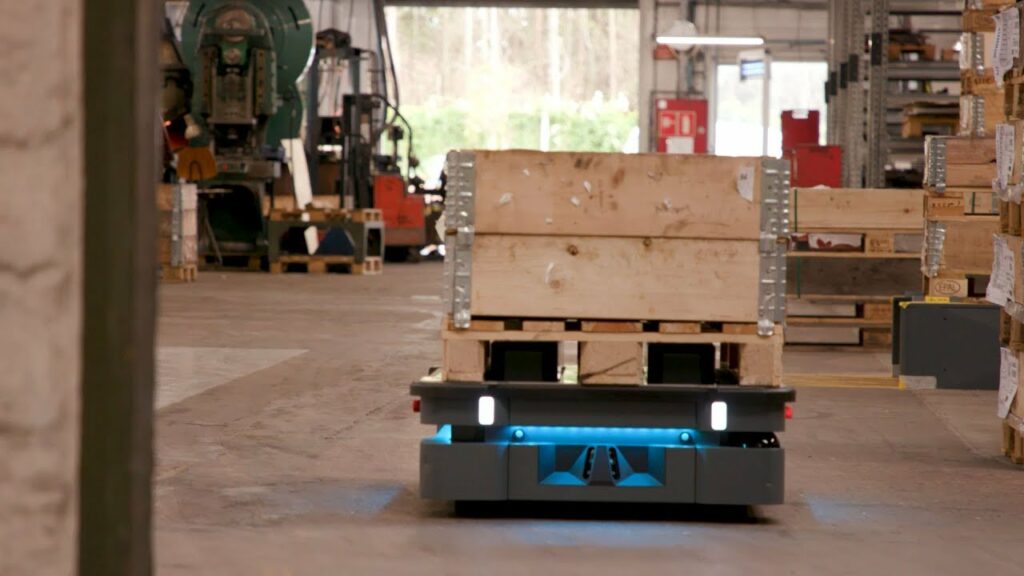

The digitization and automation of logistics processes is finding its way into more and more sectors and is becoming increasingly important to remain competitive. New technologies can ensure that logistics processes become more flexible and accelerated. Automating these logistics processes is done with Automated Guided Verhicles (AGVs) and Autonomous Mobile Robots (AMRs). Vehicles that drive guided or autonomously through the warehouse or factory to transport boxes and carts. In the long run, this delivers a number of benefits. Which ones are they, you can read in this blog!

Improving security

The AGVs and AMRs are equipped with various sensors and laser navigation. In addition, these robots will always adhere to safety regulations. If someone approaches and is in the way, the AGV will stop and the AMR will move around it. This means that unsafe behavior by forklift truck operators or people moving around them is becoming less common and therefore accidents are becoming less frequent.

Reducing labor costs

In addition to the difficulty of finding qualified personnel, staff members also tend to entail a lot of costs. By automating the internal logistics process, the entire organization becomes more productive and you as a company can do more with fewer people. Ultimately, this leads to lower labor costs relative to production.

Processes are organized more efficiently

Internal logistics processes are often boring, monotonous jobs. Employees will eventually struggle to perform this work with concentration, making them less efficient. Automated vehicles can theoretically work 24/7, will not get distracted and will always choose the most efficient route through the warehouse. This makes the process more efficient, more productive and leaves workers with their hands free for other work.

Fewer errors, less damage

Within logistical processes, things sometimes go wrong. Goods are damaged, which costs time and money. Robots and therefore also AGVs and AMRs make fewer mistakes than people. This reduces the chance of damage to goods considerably and that in turn saves on the cost of repairs.

Starting with logistical automation

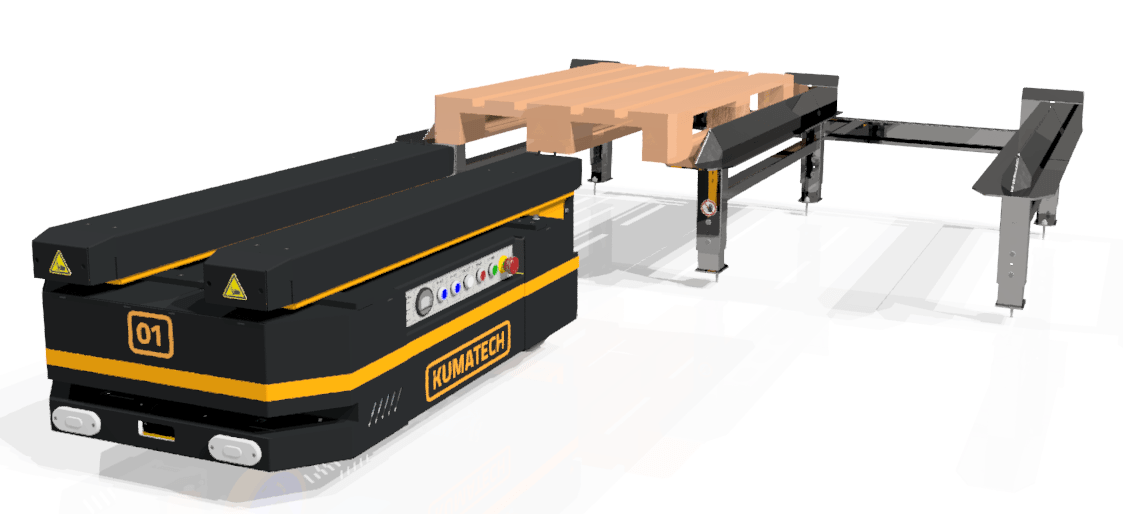

In times of Industry 4.0 and workforce shortages, automation is a great way to stay competitive and future-proof. We, WiredWorkers, specialize in logistics automation and offer solutions with the state-of-the-art AGVs and AMRs from MiR and Kumatech. A cost-effective, user-friendly, performance-enhancing and versatile solution with built-in software that allows operators to get started.

Curious about the possibilities? Contact us or schedule a free cobot consultation!