Ensuring production quality is one of the most important processes within the manufacturing industry. Faulty or poor-quality products not only cost the company money, but also time, returns, stress, reduced profitability and possibly even the loss of customers. Cobots can play an important role in production quality testing. How? We'll explain!

Quality inspection with cobots

For a long time, automating testing activities was not feasible for many companies. The costs involved did not outweigh the ultimate benefits, which meant that much quality inspection was still done by employees. Although people are perfectly capable of performing quality inspection, it is more error-prone than if it were automated. Over time, fatigue sets in, concentration decreases and eventually more mistakes will be made.

The advent of collaborative robots has made it more commercially attractive to automate quality inspection. Cobots are versatile, cost-effective and easy-to-use robots that companies of almost any size and level of technical expertise can work with. This allows a wider range of companies to automate quality inspection and minimize the margin of error.

How can a cobot help with quality inspection?

A cobot can perform testing operations in a variety of ways. For example, it can load products into a testing machine, it can perform optical inspections through vision, and it can take measurements using sensors.

Load testing machines

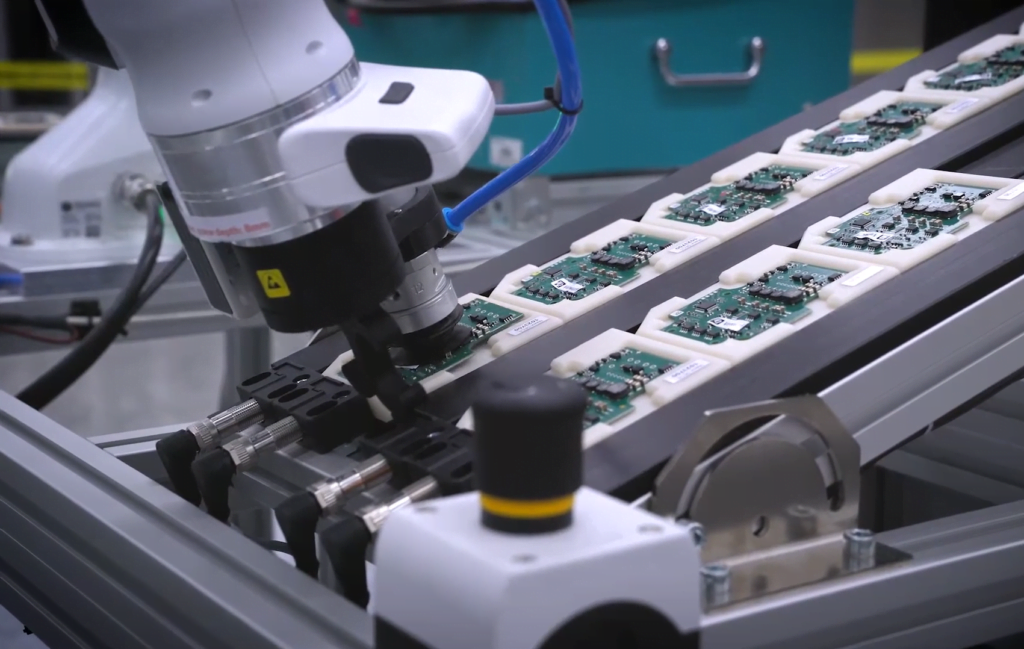

One of the most common quality inspections a cobot can perform is loading test machines. Examples of this are endless. In laboratories, samples are loaded into test machines, for example, but the most well-known is the automated testing of computer chips, such as Pcb's. Because these chips are very sensitive, it is important to handle them in a careful manner. Cobots are equipped with various sensors that make them extremely sensitive and can gently pick up the most delicate chips using vacuum grippers.

Another advantage of collaborative robots is the user-friendly software and the fact that they are designed according to the Industry 4.0 principle. This ensures that communication with a test machine is easy to set up, even by workers with somewhat less robot expertise.

Testing using sensors

Cobots themselves are equipped with various force sensors that can measure force extremely accurately, but it is of course also possible to add external sensors. Suppose products are being produced that need to be the same in length down to the millimeter. A cobot could pick up these products and pass them past a sensor that measures the length of the product, then sort the right and wrong products.

Optical inspection

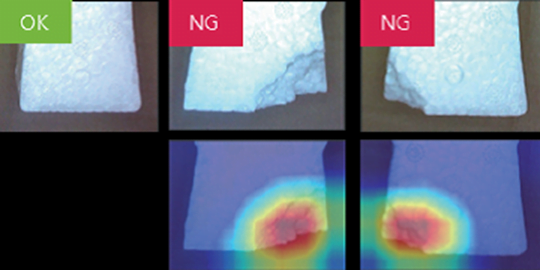

Optical inspection means that the cobot uses (3D) vision to look at products and recognize abnormalities in them. For example, Techman Robot already showed once how they visually inspected printed circuit boards and chips with a camera, to check for abnormalities. Not only chips are suitable for this, but also milling parts from a milling machine, for example. If there are products to be produced in large series, it is possible to show the cobot a product of good quality. It can then use its camera to pass by the other products and recognize irregularities and filter them out. It is also still possible to store all this image data so that you can track early where problems are coming from.

Getting started!

In addition to the various options, there are also several benefits of automating testing operations. Not only do workers have their hands free to do other things, inspection accuracy goes up. The margin for error is reduced because cobots, despite having to go on for hours at a time, will never lose concentration. Not to mention cost savings and increased productivity.

WiredWorkers is an expert in automation and has already helped several companies implement automated quality inspection. Contact us or schedule a free cobot consultation!