Cobots are designed to work safely alongside human operators and can take over repetitive, tedious or dangerous tasks from them. Not only does this present new opportunities for companies to increase productivity and efficiency. It is also an opportunity for employees to gain new skills and knowledge to work with this technology. In this blog, we discuss the importance of human skills in a world of collaborative robots.

Positive impact of collaborative robots on the future of work

One of the main ways collaborative robots can affect the future of work is by creating new opportunities for workers. By taking over repetitive or dangerous tasks, collaborative robots can free workers from monotonous and potentially harmful tasks, allowing them to focus on tasks that require more skill and creativity. This can lead to greater employee satisfaction and motivation, and enable them to make more valuable contributions to the organization. Moreover, collaborative robots can increase employee efficiency and productivity. These robots are able to perform tasks faster and with more precision than human operators, which reduces lead times and improves product quality. This can result in better business outcomes and increased competitiveness.

Required skills and knowledge for employees

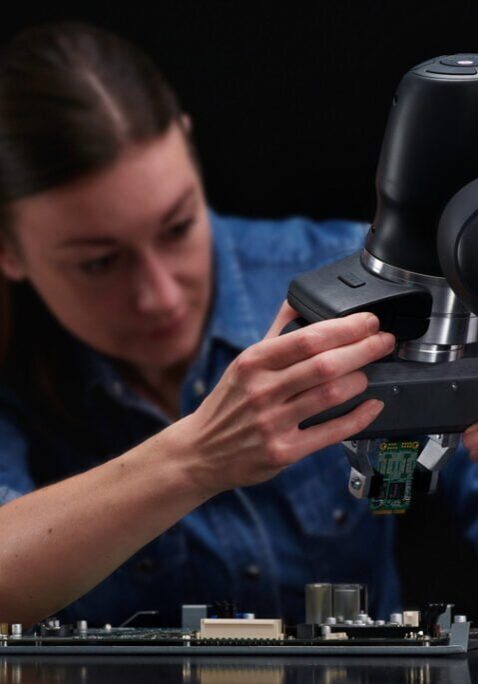

To successfully integrate collaborative robots into a manufacturing process, several skills and knowledge are required within the organization. First, production workers must be familiar with the operation and programming of the robots. This requires some knowledge of the programming language and the specific applications of the robots in their industry and organization.

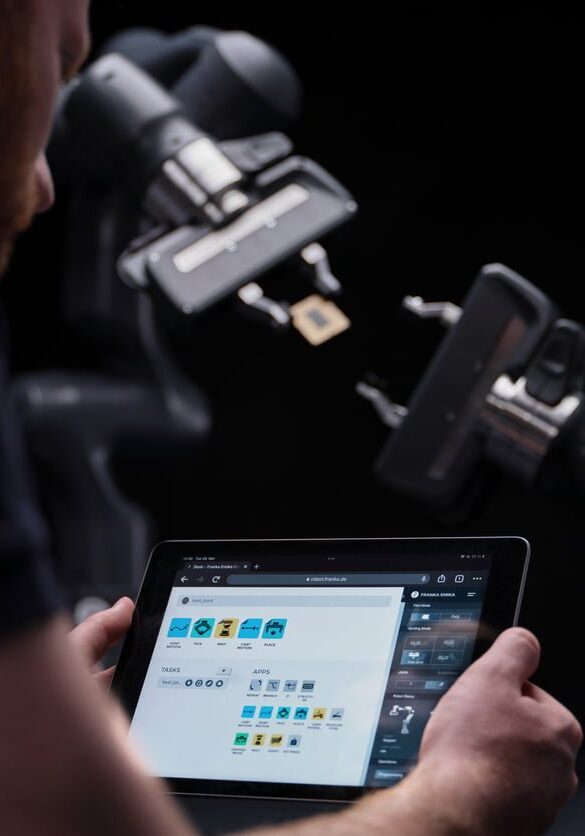

Higher-level employees must have the skills needed to effectively integrate the robots into the production line or work processes. A good example is the ability to identify tasks that can be automated, and knowledge of the tools and technologies needed to integrate the robots into the broader system.

Another important skill for workers working with collaborative robots is the ability to safely operate and maintain the robots. This includes adhering to the safety procedures established for working with collaborative robots and understanding the risks associated with working with this technology. In addition, it is important for workers to be able to work well with the robots. This requires the ability to understand and use the robots' capabilities to improve the productivity and efficiency of work processes. It also requires the ability to monitor the robots and respond to any problems that may arise.

Finally, it is important to note that collaborative robots are changing not only the skills and knowledge of workers, but also the way organizations are organized. Collaborative robots may lead to a shift in workers' tasks and responsibilities, as well as the roles and functions required within organizations. This may result in new opportunities for career development and specialization.

Challenges in implementing collaborative robots

While collaborative robots offer many benefits, they also bring challenges. One of the biggest challenges is managing the changes associated with implementing collaborative robots. This requires careful planning and communication, as well as educating and training employees to work effectively with this technology.

Another challenge is maintaining the human factor in the work process. Collaborative robots are designed to work with human operators, but there remains a need for human interaction and skills that cannot be replaced by automation. It is important that organizations and workers remain aware of this need and the value of human contributions to the work process.

Getting to work!

In other words, collaborative robots have the potential to change the future of work by creating new opportunities for workers and increasing efficiency and productivity. Working with this technology requires specific skills and knowledge, as well as careful planning and communication to manage implementation. As organizations and employees adapt to this new technology, it is important to retain and value the human factor in the work process. Collaborative robots can be a valuable addition to the work process, but they will never replace the value of human interaction and skills.

WiredWorkers is an expert in automation and has already helped several companies implement cobots. After an implementation, we ensure that the cobot can work optimally and that employees have the right skills to work together with the robot.