Within the mechanical engineering industry, efficiency is critical. Manufacturers are constantly seeking ways to optimize their production processes, improve product quality and minimize downtime. In this quest for improvement, machine learning algorithms are taking an increasingly prominent role. In this blog, we take a closer look at how machine learning is being applied in tasks such as maintenance, quality control and optimization of manufacturing processes, and how it is transforming the mechanical engineering industry.

Predictive maintenance: acting before problems occur

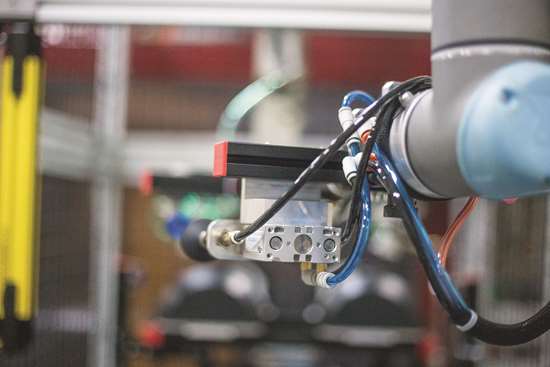

Predictive maintenance is the most promising applications of machine learning within the machinery industry. Instead of waiting for machines to make errors and require action, predictive maintenance uses advanced algorithms to identify potential problems before they occur.

Machine learning algorithms can be trained on historical machine performance data, such as vibration patterns, temperature fluctuations and part wear rates. By analyzing this data, the algorithms can recognize patterns and anomalies that indicate potential problems. Based on this analysis, maintenance teams can take proactive action, such as replacing parts before they break down or scheduling maintenance stops at times when production is least affected.

The result is a significant reduction in unplanned downtime and lower maintenance costs, while maximizing operational efficiency. In addition, predictive maintenance allows manufacturers to extend the life of their machines and improve the overall reliability of their production lines.

Quality control: detection of deviations with precision

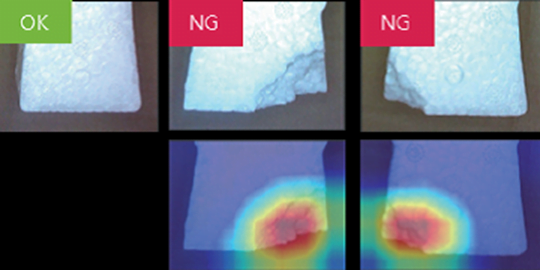

Another important application of machine learning in mechanical engineering is quality control. Manufacturers are constantly looking for ways to ensure the quality of their products and minimize defects. Machine learning provides a powerful tool to achieve this through advanced pattern recognition algorithms.

Machine learning algorithms can be trained on large data sets of product images, sensor data and other relevant information to learn the characteristics of a high-quality product. Then these algorithms can be used to detect deviations from these normal patterns during the manufacturing process.

For example, in an electronics production line, machine learning algorithms can be used to identify deviations in the soldering quality of printed circuit boards. By learning the visual characteristics of acceptable and unacceptable soldering, the algorithms can automatically identify and remove defective products from the production line.

This results in improved product quality and reduced waste and recalls. In addition, machine learning allows manufacturers to continuously improve their quality control processes by leveraging the feedback loop between production and quality data analysis.

Optimization of production processes: getting the most out of production

Machine learning can also be used to optimize manufacturing processes to improve operational efficiency and reduce costs. By applying advanced algorithms to production data, manufacturers can understand the factors affecting the performance of their production lines and devise and implement strategies to optimize them.

Machine learning algorithms can develop predictive models that forecast production volumes based on variables such as demand patterns, available capacity and operational constraints. With these predictive models, manufacturers can optimize their production schedules to fully utilize capacity while minimizing costs.

In addition, machine learning algorithms can be applied to process data to identify hidden inefficiencies and bottlenecks. These insights allow manufacturers to make process improvements that lead to higher output, shorter lead times and lower operating costs.

The power of machine learning in mechanical engineering

Machine learning has the potential to transform the mechanical engineering industry through advanced applications such as predictive maintenance, quality control and optimization of manufacturing processes. By using big data and advanced algorithms, manufacturers can improve operational efficiency, ensure product quality and save costs. Looking ahead, machine learning will continue to be an integral part of the machinery industry, developing new applications and innovations to improve manufacturers' performance and competitiveness.

We, WiredWorkers, have helped countless companies get the most out of their production. Contact us today or schedule a no-obligation online consultation!