There are many misconceptions about robot vision systems. It is often thought that the integration of a vision system is complex, expensive and difficult. In addition, reliability is questioned. Thanks to the emergence of new technologies such as machine learning and artificial intelligence, costs are falling and it has become much more accessible to apply vision. How does robot vision work? And what can you do with it?

How does robot vision work?

Robot vision works by integrating one or more cameras into the robotic system. A camera is mounted at the end of the robotic arm that acts as the "eye" of the machine. Alternatively, the camera may be placed separately from the robot. These cameras and the associated software can recognize objects and scan barcodes and QR codes. During programming, the robot learns to identify objects and codes it needs to work with. 2D or 3D scans are made of these, which are stored in the software. It is then possible to assign specific tasks to them.

The capabilities of robot vision

An integrated vision system creates a number of opportunities for robots that did not exist before. For example, robots equipped with a camera can perform optical inspections, sort objects and take measurements.

So, a robot could see at the end of an assembly process if the products are assembled properly. A good example is the inspection of a motherboard after it has been soldered. Thanks to Artificial Intelligence, the robot learns when a product does or does not meet quality requirements in order to then sort them. Sorting can also be based on QR or barcode, something that can be very useful within logistic processes. For example, the robot could learn, based on the code on a box, on which pallet it should be stacked.

Benefits of vision

In addition to the fact that the robot learns a number of new tasks, vision also has a number of advantages for usual tasks. For example, in the set-up of a relatively simple pick-and-place. The biggest challenge in getting such a set-up working is that the objects are always presented to the robot in exactly the same way and in the same place. This means that devices or constructions must be added, such as a feeding system, so that randomness is prevented and the robots know exactly where the object is located.

Thanks to vision, the robot can see where the products are located. A standardized supply is then not essential and objects could be supplied to the robot in bulk. Bin picking is an example of this.

And what if the supply is standardized, but different types of objects in different shapes have to be worked with? Or what if the print run is in smaller numbers and there are frequent product changes? Then it is important that the robot can be quickly converted and can pick up and recognize new objects. This is possible with vision. It is even possible to switch between parts and products on the same line. Because the robot recognizes the object, it knows what the next step in the process is. This provides more flexibility to build different units on the same line without having to reprogram a "blind" robot that expects the same thing every time.

Different camera types

Once the decision has been made to get started with robot vision, it is good to look at exactly what is needed because not all vision solutions are the same. The difference is in cost, flexibility, ease of use and software capabilities. There are two types of camera types; 2D, 3D.

2D cameras are the cheapest, but with that also the least comprehensive in terms of functions. They can determine the length and width of an object, but are unable to determine its height. Within these limitations, however, they are very reliable.

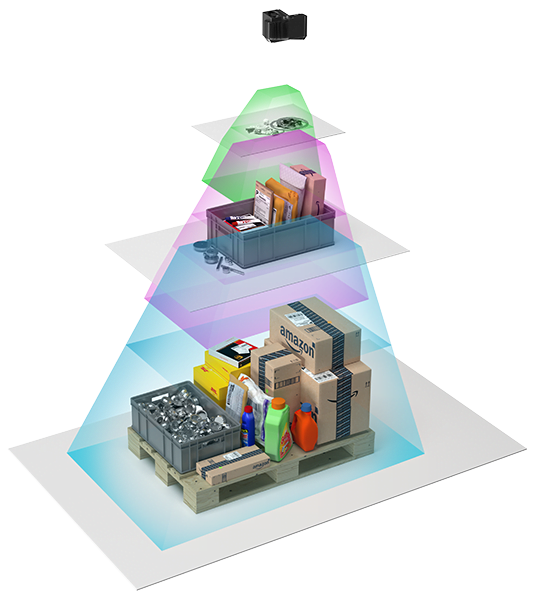

3D cameras can determine all three dimensions (length, width, height). This gives the robot numerous possibilities, but this comes at a price. 3D cameras are the most expensive on the market and in terms of reliability they are slightly weaker than the 2D camera. Because a 3D camera can determine height, it is ideal for products that vary in height, or for stacking products. Think palletizing or packing boxes.

Not all vision systems are the same. Some systems are easier to set up and calibrate than others. There are also vision systems that must be mounted directly to the cobot, which creates limitations, while others can work independently of the robot.

Built-in vision

Techman Robot's collaborative robots are unique on the market because they have a built-in vision system. These are integrated into both the hardware and the software. Functions such as pattern matching, object localization, barcode scanning and color recognition are therefore relatively easy to program with a Techman.

WiredWorkers specializes in integrating robot vision and is a certified integrator of the Techman Robot. Want to learn more about how vision and collaborative robots can help optimize your production process? Contact us or schedule a free cobot consultation.

Frequently asked questions

What are the benefits of using robot vision in production processes?

Robot vision provides several benefits in production processes, such as enabling optical inspections, sorting objects, and taking measurements. It enhances quality control, reduces errors, and increases efficiency.