Robotisation, opportunity or threat to SMEs?

Robotisation of the labour market has been on the move for several decades, but much has changed in recent years. Large industries such as the automotive industry have already largely benefited from robots and automated large parts of the production process. On the other hand, it is not easy for small companies to robotise. The high costs and knowledge required to make robotization possible are a hindrance. How can SMEs best deal with robotisation? Embracing or fighting against it?

Why robotisation is difficult for SMEs

Many processes within the SME sector are changeable. Small companies often run a so-called high mix, low volume production process. In this production environment, the end products vary in application, batch size and therefore also the process. This means that the production processes do not run in exactly the same way every day and that there is a difference in the number of volumes. The advantage of this method of production is that they can change product requirements and adjust the production line within a few hours, sometimes even minutes. This is also necessary if you mainly supply customer-specific products, or custom-made products, like in the electronics and metal industry. It is not easy for robots to perform a different task every day. A robot is designed to do the same thing day in, day out and it takes time to reprogram a robot. Time that an SME doesn't have.

In addition, the purchase of a robot is expensive. The costs of an industrial robot quickly amount to tens of thousands of euros and internal knowledge is often also a requirement. The installation takes a lot of time, the robot takes up a lot of space and in order not to endanger the other people on the shop floor, they have to be covered by safety screens. Reasons enough to leave robotisation as it is and to make processes run as smoothly as possible without robots.

How do you compete?

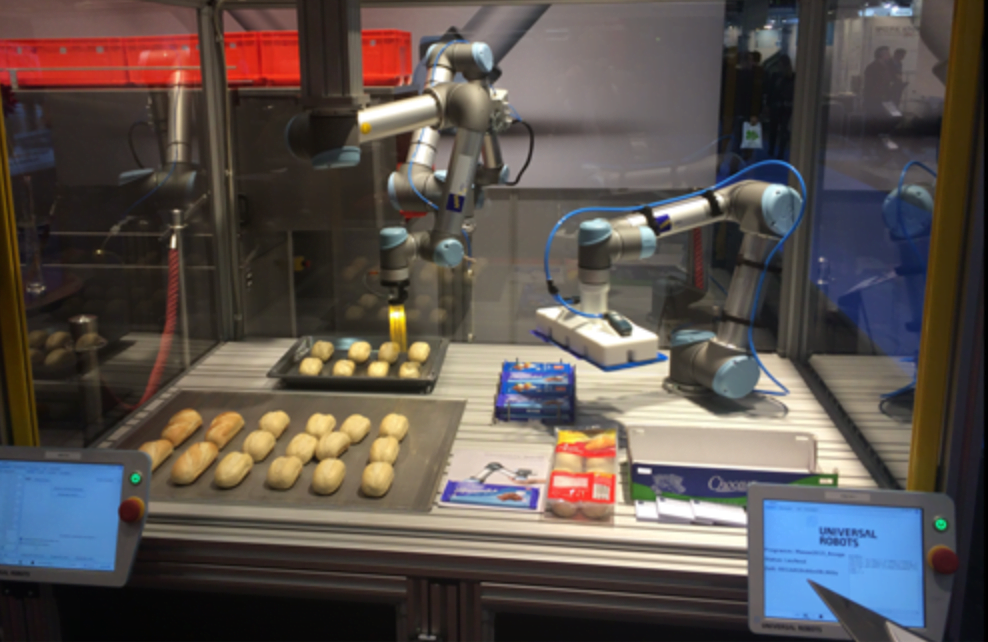

So the choice not to robotize seems justified, but the world around us is changing rapidly. A new generation of robots is emerging and they are perfect for SMEs. These are collaborative robots, or cobots.

Most of the problems that robotization causes for SMEs do not apply to a cobot. Starting with programming the cobot. With simple software, it is accessible to everyone to program this robot and there is no need to bring in any knowledge to have it perform an action. Also, programming the cobot is not a time-consuming job, this can be done within an hour. Having him do something different every day is no problem. The installation of a cobot can also be done within the foreseeable future. Watch the video below in which the Franka Emika Panda is installed within 15 minutes.

The special thing about cobots is that they are designed to work together with people. The robots have built-in sensitivity and can support people in their work. Safety screens are therefore in principle no longer necessary and it is possible to work in a shared workspace with employees of flesh and blood. They are also compact and mobile. Mounted on a mobile workbench, they can perform their tasks at a different location every day and because they are so compact, they fit almost anywhere.

Besides the fact that cobots allow SMEs to automate, these special robots have another function. The robot's built-in sensitivity and intelligence allows them to work with and support people. This creates a pleasant working environment in which employees no longer have to perform boring, colourless, monotonous work. Creative, solution-oriented work can be carried out by employees while the cobots do the hard work. Ultimately this results in an improvement of the work happiness, the working atmosphere and the personal development of the employees.

Unique characteristics of cobots

The special thing about cobots is that they are designed to work together with people. The robots have built-in sensitivity and can support people in their work. Safety screens are therefore in principle no longer necessary and it is possible to work in a shared workspace with employees of flesh and blood. They are also compact and mobile. Mounted on a mobile workbench, they can perform their tasks at a different location every day and because they are so compact, they fit almost anywhere.

Besides the fact that cobots allow SMEs to automate, these special robots have another function. The robot's built-in sensitivity and intelligence allows them to work with and support people. This creates a pleasant working environment in which employees no longer have to perform boring, colourless, monotonous work. Creative, solution-oriented work can be carried out by employees while the cobots do the hard work. Ultimately this results in an improvement of the work happiness, the working atmosphere and the personal development of the employees. In addition, they also work very precisely and can carry out movements down to the last millimetre. Perfect for welding, for example.