Collaborative robots are becoming a significant factor in various industrial sectors. They have the potential to redefine traditional work processes, support human operators and give companies competitive advantages. In this blog, we discuss the role of collaborative robots in improving efficiency, productivity and quality.

The impact of cobots on efficiency

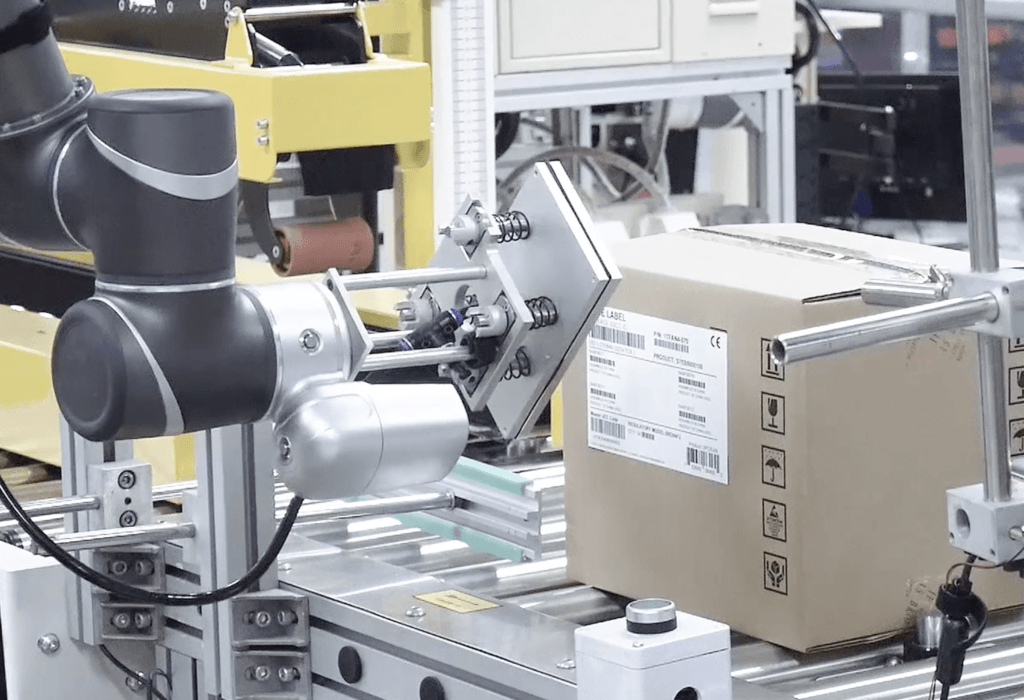

One major way collaborative robots increase efficiency is by taking over repetitive tasks and heavy physical labor from human operators. These robots are programmed to perform precise and repeatable tasks with constant precision and speed. This allows human operators to focus on tasks that require more creativity, problem-solving skills and human interaction. By automating repetitive tasks, companies can improve the overall efficiency of their processes, reduce production time and increase throughput.

Improving productivity with cobots

In addition, collaborative robots can help increase productivity by reducing cycle times and speeding up turnaround time. Cobots, for example, can work seamlessly with human operators in a cooperative environment, combining human input with their own speed and precision. This results in higher output and faster completion of tasks. In addition, cobots can work 24/7 without fatigue, further increasing productivity compared to human workers with limited working hours.

How cobots improve quality

Another advantage of collaborative robots is their ability to improve the quality of products and processes. These robots are equipped with advanced sensors and cameras that can perform precise measurements and inspections. They can check products for defects, detect dimensional deviations and ensure compliance with quality standards. In addition, cobots can ensure repeatability in manufacturing processes, achieving consistency and uniformity in the final product. By reducing human error and variability, collaborative robots can help increase product quality and minimize the likelihood of rejection.

Not only does the quality of products improve, but the quality of work becomes more pleasant for workers. Collaborative robots contribute to improved workplace ergonomics. They can take over tasks that are physically demanding for human operators, such as lifting, carrying or standing for long periods of time. This helps reduce work-related injuries and fatigue, resulting in higher productivity and lower health risks. Moreover, cobots can be flexibly adapted to different work environments and ergonomic requirements, improving overall working conditions and promoting a safe work environment.

Improved flexibility

Finally, collaborative robots allow companies to respond quickly to changing market demands and product variations. Cobots can be easily reprogrammed and reconfigured to handle new tasks and processes. This enables companies to respond flexibly to changes in production needs and customer requirements, increasing their competitiveness.

Getting to work!

In other words, collaborative robots play a crucial role in improving efficiency, productivity and quality in various industry sectors. By taking over repetitive tasks, reducing cycle times, providing quality control and improved ergonomics, cobots contribute to improved overall business performance. They enable human operators to focus on more complex tasks and provide flexibility to respond quickly to market changes. With these benefits, collaborative robots remain a valuable addition to modern manufacturing and business environments.

WiredWorkers is an expert in automation and has already helped several companies implement collaborative robots. Contact us or schedule a free online consultation!