Even with the latest technologies and the newest sanders, sanding remains a difficult, time-consuming and repetitive task that demands a lot from workers on the shop floor. Manual sanding increases the risk of RSI, whiter finger syndrome or worse. In addition, it is difficult and strenuous for operators to perform sanding tasks consistently throughout an entire shift. Thus, a high probability of quality problems with the final product!

These problems make automating sanding operations ideal for improving the quality of labor and finished product and for making the production process more efficient. Mind you, there are a number of factors to consider when buying a robotic sanding system. Which ones they are, you can read in the article below!

The application

It is important to focus on one specific manual sanding process that you want to automate. Break it down into different parts and see which elements can be automated. In doing so, it is important to establish some key criteria to evaluate whether automating this task is worthwhile. In addition, it is important to ask yourself a number of questions, such as; How heavy are the sanding tasks? Does it involve one type of product or mixed batches? How much time and resources are currently spent on manual sanding operations? Once you have all this in a row you can start looking at which robotic sanding system might be of use.

The Mimic Sander

A beautiful sanding tool that excels in usability is the Mimic Sander from Nordbo Robotics. An innovative, automated sanding machine that uses robotics and artificial intelligence. This machine is designed to automate manual sanding to increase productivity and improve the quality of the finished product.

The Mimic Sander uses an innovative system called "mimicry," which enables the machine to mimic an operator's movements and repeat those movements with a high degree of precision. This allows complex and detailed surfaces to be sanded with constant pressure, without the fatigue or inconsistent results that can occur with manual sanding.

The machine is equipped with various sensors and camera systems that capture the operator's movements and convert this information into an accurate and consistent sanding motion. In addition, the Mimic Sander is easy to program and adapt to different surfaces and materials.

Consider the different options

Robots outperform humans when it comes to sanding. Note that not all robotic sanding systems are the same. Automatic sanders have been around for years, but are often pricey, difficult to program and take up a lot of physical space. They can often handle heavy sanding tasks, but only in mass production environments. For SMEs, where there is often high mix/low volume, traditional robotic sanding systems are therefore not interesting. For this group, it is more interesting to choose a collaborative sanding solution. Collaborative Robots are lightweight, compact, mobile robots that can safely work together with humans.

Budgetary investments

Traditional industrial robots can perform sanding operations at a high-quality level, but they are also often expensive and complicated to program. Therefore, expert integrators and programmers are required, making the automation process more expensive and complicated. The additional functions and features of cobots make them a cost-effective, attractive choice for a wide range of sanding operations.

Versatility

Collaborative robots are mobile and not as heavy compared to industrial robot systems. By mounting them on a mobile workstation, you create the possibility of having the robot do its work in different places in the company. The software is user-friendly, making it easy to teach the robot new tasks. This allows the robot to be converted to a new task in no time. Useful if there is a lot of variation in the end products or if help is needed during peak pressures. Traditional robots are less versatile. They are bound to a fixed workplace and to make them work profitably, as little variation as possible is needed.

Safety

Safety is obviously the most important thing for employer and employee. Traditional robot applications require safety cages and extensive safety protocols. With collaborative robots, things are a little different. These are designed to work with people and are safe around people under certain conditions. Collaborative robots are equipped with sensors that give the robot "feel". If the robot is interrupted in its actions, it will go into safety mode and stop, unlike traditional robots that simply continue with their work. As a rule, therefore, it is possible to place workers safely next to a collaborative robot.

In house expertise

It's good to look at what qualities you have in house beforehand. How much experience does the team have with robot programming? How much experience does the team have with operating and maintaining robots? How much training is needed to handle both the robot and the sanding tool? Do expert robot programmers need to be called in if there is a problem with the system?

Collaborative systems offer a real advantage here because they are easy to program. These setups can be operated by people with little robot experience. If the company can handle robot programming (and a large investment in hardware), it may make sense to consider a traditional industrial robot - or an automated sander - for your sanding processes.

Different robotic systems

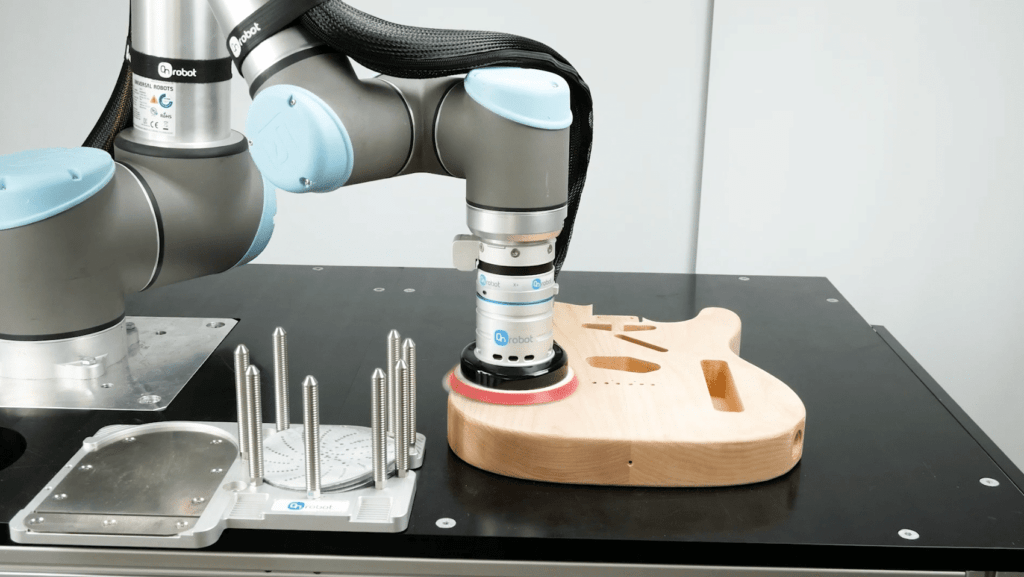

As you've seen, there are several options and a number of factors to consider when starting to automate sanding operations. We, WiredWorkers, specialize in collaborative robot solutions. We offer several cobots with different end-of-arm tooling (such as the OnRobot Sander) that you use to automate sanding operations. Cobots always deliver the same amount of pressure to the surface thanks to built-in sensors and can be deployed at different points in the production line. In terms of cost, ease of use, performance and versatility, it is a groundbreaking product that combines an unprecedented level of user-friendliness with consistent sanding performance.

Curious about the possibilities? Contact us or schedule a free cobot consultation!