SME manufacturing companies regularly face many challenges. From competing with large manufacturing companies, which have more resources, to striving to improve productivity and maintain quality. In addition, every now and then temporary challenges are added, such as meeting guidelines in times of pandemic or supply chain issues. In this blog we discuss the 5 biggest challenges for manufacturing SMEs and solutions to overcome them.

Shortage of employees

The shortage of employees is a global problem in manufacturing. In the Netherlands, 34% of entrepreneurs say that finding qualified personnel is the biggest obstacle in their business operations. On top of that, compared to a few years ago, it is harder to find talent. Demographic factors also play a role here. For example, a large proportion of the production workforce is 55 years and older. At the lower end, there is little young staff added, which means that when some of the staff retire, they are not replaced quickly enough.

In addition, employee desires have changed. Much more than in the past, employees desire a modern, digital work environment. The younger workforce are digital natives who have expectations in terms of digitization and automation. Something that SMEs find harder to meet due to the complexity and cost of traditional automation and digitization solutions.

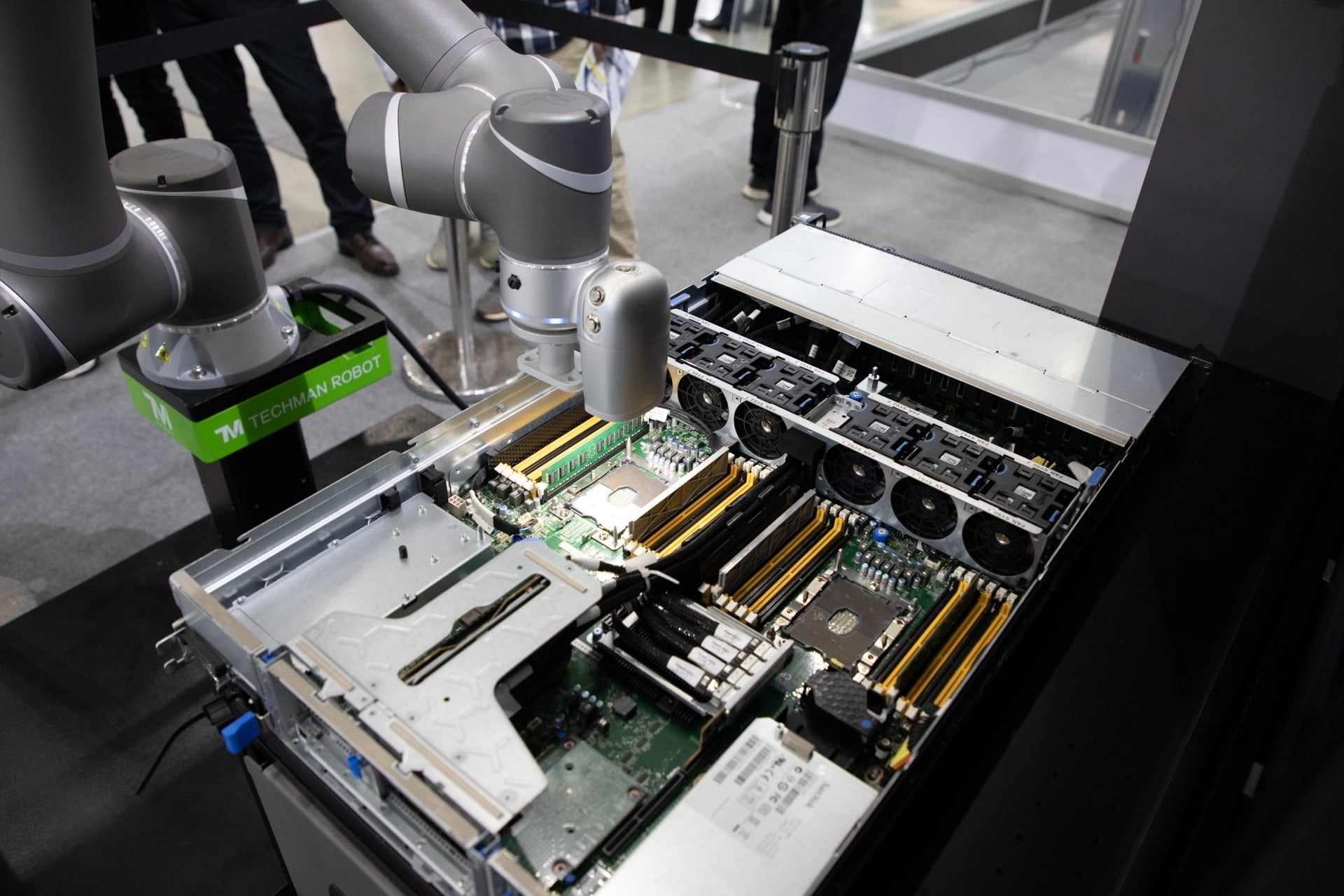

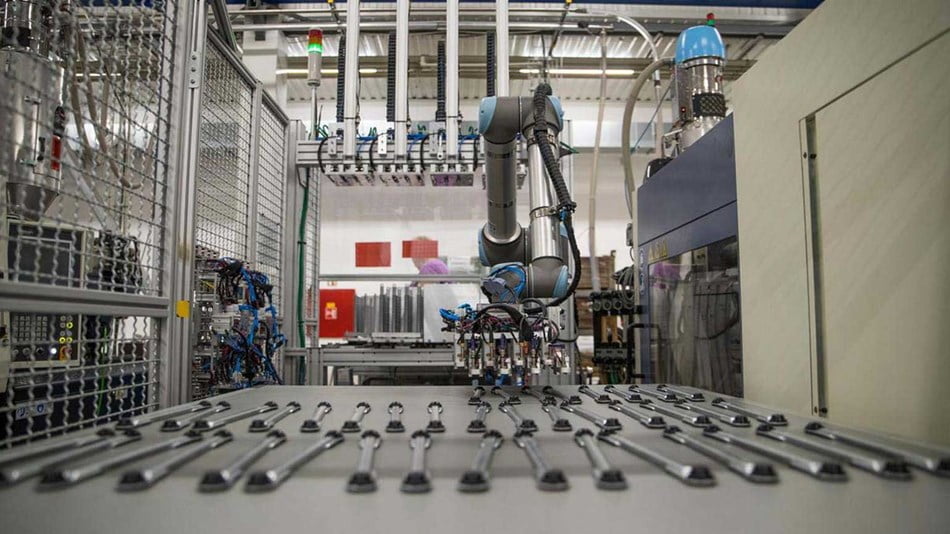

Cobots can help with this in several ways. Not only can they make up for staff shortages and take tasks off the hands of staff. This increases productivity and gives employees the space to do other work. In addition, collaborative robots fit into the current picture of modern industry, in which digitization plays a major role. These robots are also easy to operate (i.e. not complex) and are generally more cost-effective than traditional automation solutions.

Supply issues

Supply chains in a wide range of industries have been disrupted by the pandemic and recovery is slow in coming. For many parts and products, demand exceeds supply, causing the gap between production and orders to widen to a record. The aforementioned shortage of production personnel is also contributing to this.

All of these developments have created a new vision for manufacturing. Instead of the model in which parts were produced and shipped around the world, it is becoming increasingly important to produce locally so that supply is closer to the customer and consumer.

For many SMEs, this is an opportunity, provided they have the right automation capabilities. The use of cobots is an example of a technology that allows local production to be ramped up and become more productive with existing resources, without immediately incurring large costs and complex processes.

Quality improvement

By improving the quality of production and products, customer satisfaction increases and price is more manageable. In fact, it reduces waste and, consequently, overall costs. Collaborative automation is often used to automate quality processes and testing. Robots can use vision to take over inspection tasks from operators, leading to higher reliability. On the other hand, cobots can take over tasks that are heavy or burdensome for humans, leaving their hands free to perform quality testing.

Remain competitive

Staying competitive is a permanent challenge for many companies. Globally, manufacturers are optimizing processes that bring productivity gains and cost reductions. Automation and digitalization are the keys to success here. SMEs are not suited to traditional automation options due to cost and complexity. So SMEs have been a bit left behind in this regard in recent years.

As mentioned; collaborative robots are ideally suited for SMEs because thanks to user-friendly software, they are not as complex as traditional automation solutions and the acquisition cost is also relatively cheaper.

Sustainability

Led by measures to combat global warming and be more frugal with the resources our earth has to offer, companies of all shapes and sizes need to produce more sustainably.

Initiatives that come with this include reducing waste, implementing flexible production processes, and improving employee ergonomics and safety. In addition, rising energy costs are the reason many companies have started looking at how to save energy.

Start with collaborative robots

It is clear from the above story that collaborative robotics can enable SMEs to get started with automation and no longer have to choose traditional automation or not automate at all. Automation has become easier, more affordable, safer, more reliable and suitable for businesses of all sizes. It helps fill labor shortages, improve worker ergonomics and attract digitally oriented staff. It increases productivity, helps relocate production, increases competitiveness and helps companies produce more sustainably. WiredWorkers is a specialist in collaborative automation and can help implement it.

Curious about the possibilities? Contact us or schedule a free cobot consultation!