In the food industry, the demand for automation is growing steadily, driven by several developments. Factors such as worker safety, stricter food safety standards, growing demand and the urgent need to increase productivity and reduce production costs are forcing food manufacturers to continuously evolve. To what extent have collaborative robots, or cobots, helped address these challenges?

Cobots and their physical benefits

While industrial robots work independently and completely take over a particular task, cobots are collaborative. This means they can work together with humans and not instead of humans. Their main task is to create a hybrid working environment that does not affect the workforce but improves efficiency and safety across all sectors and tasks. Cobots help people speed up tasks and streamline operations. They also take over monotonous and boring work, leaving the more challenging part of tasks for humans.

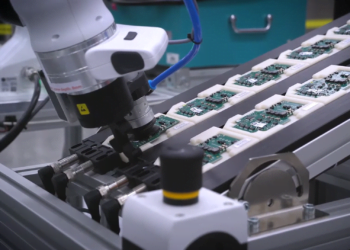

Another advantage of a collaborative robot is that it is easily programmable and can work in almost all industries, including the food and beverage industry. Cobots are also interesting for these industries because of their physical advantages. While traditional robots are bulky, enclosed and sometimes even dangerous, cobots are lightweight and require no physical safety barriers. Their precision and agility allow them to be integrated into production lines in most environments.

Taking over everyday tasks

Despite becoming very comfortable with new technological advances, humans are still needed for tasks that require decision-making or judgement. With this in mind, cobots can replace humans for more mundane and repetitive tasks. Moreover, cobots can make the workplace safer as they can be used to take over tasks that could be dangerous for humans. As a result, people can be redeployed and tasked with higher-level responsibilities and given the opportunity to develop skills. This can result in better product quality.

Increased productivity and efficiency

According to research human inactivity can be reduced by 85% by collaborating with cobots and robots. One reason why this is so is because cobots are not affected by strenuous activity and do not need to take breaks during their working hours. They can also work overtime, always with minimal supervision. Tasks that were once handled manually and were time-consuming can now be completed very quickly and accurately. This ultimately results in more production within the same time limit. Automating the production line increases output and reduces labour costs, increasing profits and ROI.

Production flexibility

Due to the increasing demand for personalised products worldwide, production flexibility is incredibly important for the food and beverage industry. Because of this increasing demand for personalisation, it becomes a challenge to produce all products on time and distribute them accordingly. This is one of the main reasons why companies are choosing to digitise their operations. Introducing cobots is just one way to make this problem solvable. They can be easily programmed, reprogrammed and redeployed to perform multiple functions. As a result, variation in output increases, waste of resources is minimised and production costs fall.

Safer working environment

One of the most frequently asked questions is whether cobots can work alongside humans. Although cooperation between humans and robots is still evolving, cobots can work alongside humans without any problems, thanks to several safety measures. Advances in sensor and vision technology made it possible for cobots to work safely alongside humans without any problems or complications. One of the reasons why cobots are considered safe is because they are equipped with sensors that detect certain obstacles and can even prevent collisions.

For example, a safety monitor in a cobot can easily reduce speed and even stop if it detects the presence of a human worker within its working area. This not only allows cobots to work very close to humans, but they can also perform dangerous and complex tasks. As a result, safety risks and hazards are reduced, creating a safer working environment for everyone.

Getting to work!

Times are constantly changing. Technological developments also affect the food and beverage industry, especially when it comes to packaging and bottling. Cobots not only represent a helping hand; they also reduce costs and shorten the time of specific processes, which is their main advantage, especially in today's world where the demand for food is higher than ever. WiredWorkers is an expert in the field of automation and has already helped several companies implement collaborative robots. Contact us or schedule a free cobot consultation!