Within some parts of the manufacturing industry, there has been a long wait for automation. There are several reasons for this, including complexity and affordability. In recent years, on the other hand, it has become a lot easier to start automating. In this blog, we explain why.

Robots are becoming more user-friendly

Developments in the field of robot technology have been very rapid in recent years. With that, the use of robots is also becoming easier and easier. Consider the arrival of collaborative robots. These robots are specially developed with a user-friendly programming interface, so that operators without robot expertise can also get to work with them.

Robots can communicate more easily with other machines

Until and few years ago, it took a lot of customization and complex programming to get machines and robots to communicate with each other. New solutions have made this much easier. Many new models of CNC machines, for example, are equipped with integrated solutions that enable communication.

The arrival of Plug & Produce solutions

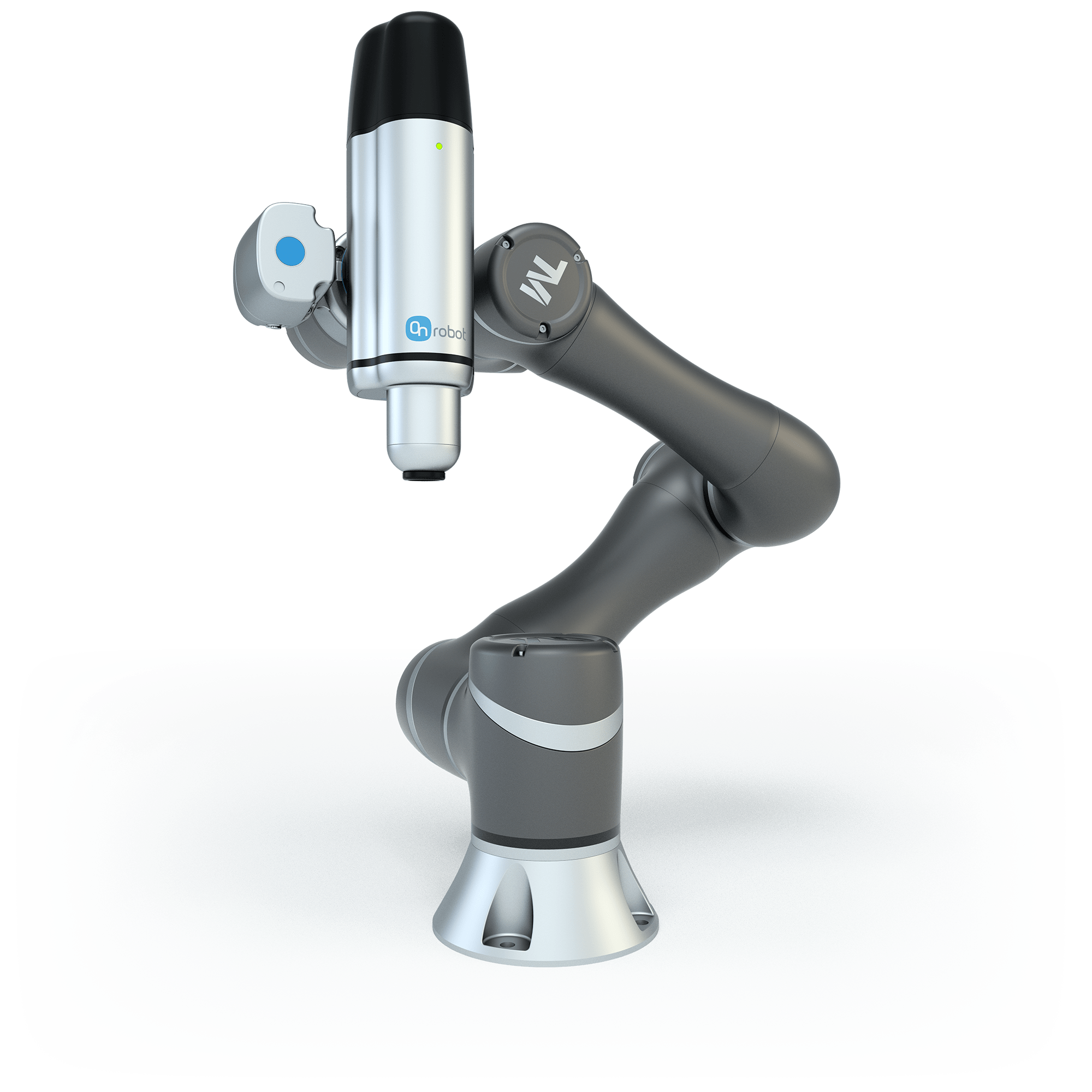

One of the developments in robotics are Plug & Produce solutions. These are standard solutions that contain everything you need to get started quickly with automation. Think of a palletizing solution, box folding solution and the machine tending solution. These contain all the components to get started; the frame, the robot, the gripper, the controller, the necessary software and accessories.

Robots have become more affordable

For many SMEs, automation was not that profitable. This was because the scale of production was not large enough. Developments in recent years and also the advent of collaborative robots have made automation increasingly affordable. This has also made it possible for companies that could not afford it before to start automation.

A reduced ROI time

Once one chooses automation, one of the most important factors is ROI. How long does it take to recoup the investment in a robotic system. As robotics has become more affordable, the ROI is also shorter. Collaborative robots in particular have a short payback period. A palletizer, for example, has a payback period of a few months.

Quick access to support and training

In addition to developments in hardware, developments in support and training have also changed considerably in recent years. Not only has this made robots easier to use, but training and documentation opportunities have also increased. All of the larger vendors of robots and tooling are investing in things like e-learning, partner portals and other platforms where researchers, developers and users can find each other.

Possible to start off small

In the past, automation often meant all or nothing. Older industrial robots were often large machines, required a large investment and demanded customization. This made it unprofitable to automate only a small part of production. With collaborative robots, this is different. It is possible to start with a small application, which can then be easily replicated in other areas of production.

Getting started!

So there are more and more good reasons to start automation. The technological developments of recent years have allowed companies of any size to start optimizing their production process.

WiredWorkers is an expert in the field of automation and has already helped several companies implement a variety of solutions. Contact us or schedule a free cobot consultation!