The problem: the loading of a press brake

Gunnebo Doetinchem is a company that develops and produces safes for ATMs. For the development of these safes, many different parts are produced, which are eventually assembled into a safe. One of these parts is metal plates that are provided with angled edge by a press brake.

In order for the press brake to do its work, products have to be continuously offered to the press brake. As soon as the press brake has tilted the product, it must be unloaded and sorted again. A repetitive, monotonous job that is not really exciting for people and does not evoke much creativity. In order to relieve employees of this task and to produce cost-efficiently, the task has been automated.

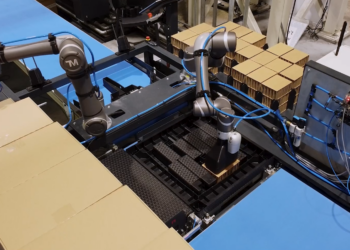

The solution: an automated process with a cobot

How did we end up with the task being automated? Eventually, a complete implementation resulted, whereby the cobot performs the edge of metal plates completely autonomously with the press brake. At the end of the Panda a vacuum piston is mounted. With this vacuum the metal plates are suctioned and picked up. The metal plates are placed in a specially made mould where the robot unpacks them. Before going to the press brake to load it, the robot gently shakes back and forth. This is to prevent multiple metal plates from sticking together and entering the machine at the same time.

The cobot places the metal plate in the press brake at the designated place. The vacuum piston stops suctioning and releases the product. Then the cobot turns in a position to push the metal plate in the right place. The controller box tells the press brake that the plate is in place and starts to edge the product.

When the press brake has done its work, the cobot gets a signal that the metal plate is ready to be picked up. The vacuum piston starts again, the cobot moves to the press brake and picks it up again. Then the cobot moves towards the designated container and places the end product. The only thing the employees have to do is deliver the semi-finished products from time to time and dispose of the finished products.

The video above shows how the cobot runs through the entire process autonomously.

Yield: A cost-efficient standardized production process.

Increased productivity »

The cobot replaces the operator for 50%. With a working week of 40 hours, this means that the operator can work 20 hours a week elsewhere.

Cost saving »

If the total investment is compared to the cost of an employee, the cobot in this case earns itself back in about 1.6 years.