Bed-of-nails test

All PCBs produced must obviously meet high quality standards, and a number of inspection and testing moments already take place during the production process.

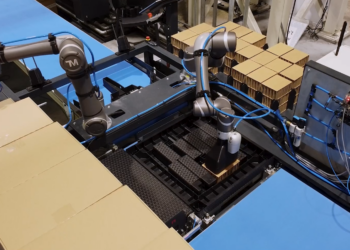

One of the test types Global Electronics uses to ensure that PCBs are delivered error-free is the pin bed. This is a system where the PCB is placed on a pin bed (bed-of-nails). The pins thus make contact with various test pads to test the quality of the PCB. For this pin bed test, WiredWorkers has developed an automatic test setup.

Automated PCB testing machine

To automate PCB testing, WiredWorkers developed an automated PCB test set-up using Techman Robot's TM5-900.

The robot uses a vacuum gripper to pick up the PCBs and then places them in one of two available testing devices. Once the test is complete, the robot receives a signal from the testing device with the outcome: good or rejected. If the product is judged as good, the robot places the PCBA in the designated bins. In the case of rejection, the product is set aside. This cycle is repeated, with enough stock available to work independently for at least 30 minutes.

Increased productivity and employee satisfaction

The implementation of the automated testing machine has resulted in a notable boost in departmental productivity. Previously occupied with manually placing PCBs into testing machines, employees now have the opportunity to engage in more impactful tasks. This shift has not only liberated them from the monotonous chore of PCB placement but has also presented them with the chance to tackle more intricate responsibilities, such as quality control and analysis. Consequently, this shift in responsibilities has led to heightened employee contentment and has significantly contributed to their overall well-being.

You may also like...

- « Previous

- 1

- 2

- 3

- 4