Light sensor test

All produced products must obviously meet high quality standards, and a number of inspection and testing moments already take place during the production process.

One of the test types used by Ott Hydromet to ensure flawless delivery of products is light sensor testing. This light sensor is used for measuring solar radiation and atmospheric properties in meteorology, climatology, hydrology, industry, renewable energy, agriculture and public health.

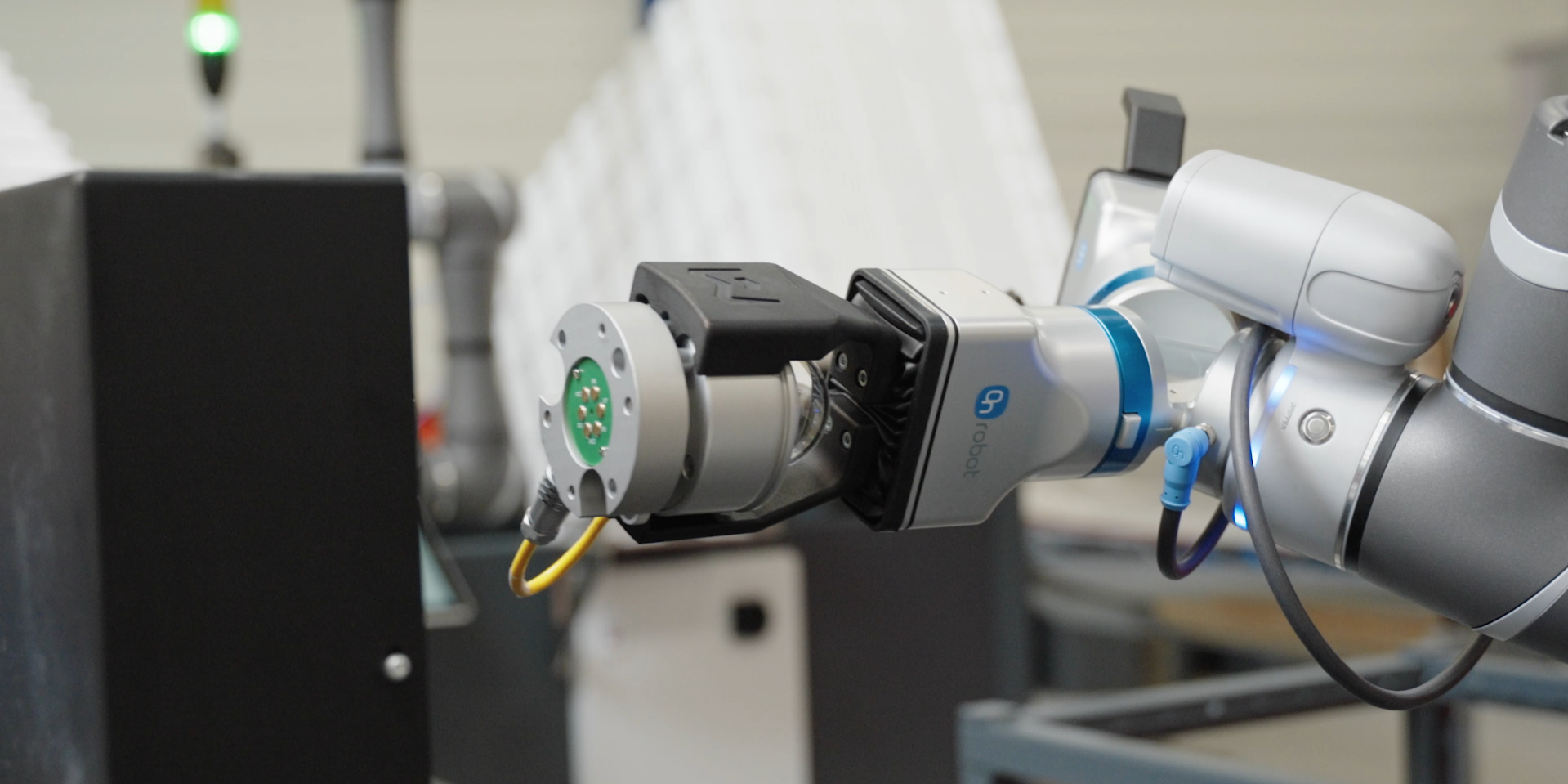

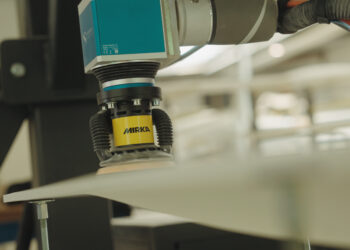

Automated light sensor testing machine

First, mobile feeding tables are placed at the cobot, after which it is started. Using a built-in camera, the cobot takes a picture of an alignment point on the table to ensure that the position of the table is known to the robot. The robot then takes a sensor from the table and places it in the test fixture. The grippers used for this are custom-made. After this, the cap is placed on the sensor, and the test can begin. This is started by the robot. The cobot then waits for the test to complete and takes the sensor from the test device again. If the test is completed successfully, the sensor is put back in its place in the table, if not, the sensor is put aside. This whole process repeats itself until all sensors have been tested.

Increased productivity and employee satisfaction

The introduction of the automated testing machine has contributed significantly to productivity gains within the department. Employees who previously had to manually place light sensors in test machines now have the opportunity to devote themselves to more impactful tasks. This change not only freed them from the monotonous task of placing sensors, but also allowed them to engage in more complex responsibilities, such as quality control and analysis. As a result, this shift in tasks has contributed to increased employee well-being and satisfaction.