What is a cobot arm?

Cobot arms are among the latest technology in the field of robots. They possess some unique features that make it more attractive for a large number of companies to automate. Traditional industrial robots were not interesting for manufacturing companies with low production volumes because they are too expensive to purchase. In addition, some robot knowledge is required and they take up a lot of space. Cobots have changed this.

Cobots are somewhat cheaper, compact, lightweight robots equipped with user-friendly programming software. As a result, they can easily learn different tasks and are not tied to a fixed workplace where the same thing must be done continuously. It is therefore an excellent solution for production companies with flexible production environments.

Working together with a cobot arm

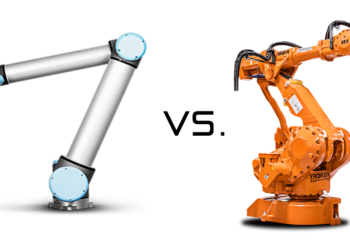

The main difference between industrial robots and cobot arms is that the last can work together with people. Cobot is a shortening of collaborative (working together) robot. It can collaborate with humans because it is equipped with sensors and therefore has " sense ". A cobot will therefore sense if it is interrupted in its path and immediately stop its work. Industrial robots would simply continue on their way, with the risk of injuring someone. This is also why they are always placed behind safety screens.

It is therefore quite possible to have a cobot (after risk analysis) working together with an employee on the assembly line, with the robot screwing something together, for example, and with the employee performing quality inspection, for example.

Wide range of cobot arms

We work to integrate cobot arms for companies that need flexible automation. We are a brand independent company with many different cobots, each with its own unique quality and specialty.

Techman Robot cobot arm

The Techman Robot has a built-in vision system in both hardware and software. With this vision system, the robot is able to recognize objects by, for example, shape or color. This means that the robot can perform sorting tasks. Moreover, the products do not have to be delivered in a standardized way. For example, the cobot could autonomously pick up items from a large container by seeing where the items are located. Techman is available in four versions, the TM5-700, TM5-900, TM12 and TM14.

Franka Emika cobot arm

The Production 3 is a robot from German manufacturer Franka Emika. The uniqueness of this robot is its high level of sensitivity. The robot is designed to act like a human arm and thanks to the many sensors it can perform complex tasks and handle delicate objects.

Installation and maintenance of the cobot arm

Are you interested in a cobot arm and automating your production line? We can help you with the integration. We start with an extensive analysis of the processes within the company that can be streamlined through automation. We develop the software needed for the cobot to perform various operations and to make programming as easy as possible. In addition, we offer training after which the cooperation with a robot will run as smoothly as possible. Eventually, a total solution will be delivered that will increase production and protect employees in stressful, repetitive tasks. Book a free consultation or contact us for mor information!