What is a cobot?

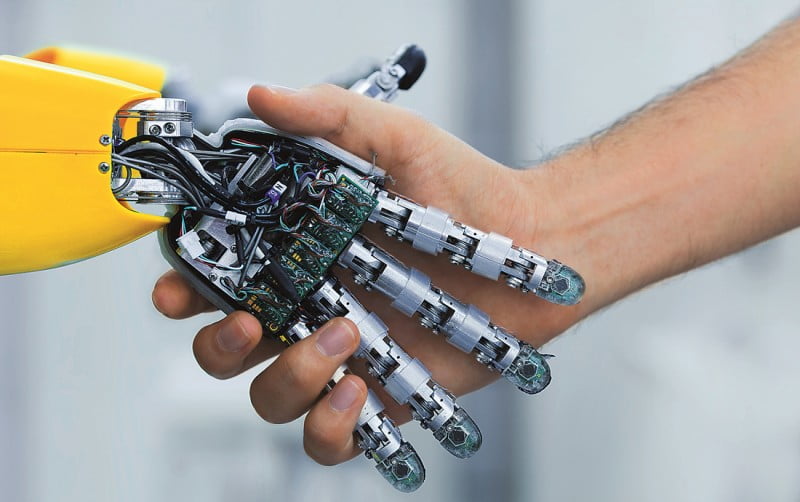

Cobots are the latest technology in robotics and have changed the world of automation significantly. The name cobot is a derivative of "collaborative robot". These robots are collaborative because they can safely work together with people. They can do this because they are equipped with sensitive sensors that give the robot "feel". If the robot is interrupted in its work, it will shoot into a safety mode. Traditional robots would simply continue their way, potentially injuring people.

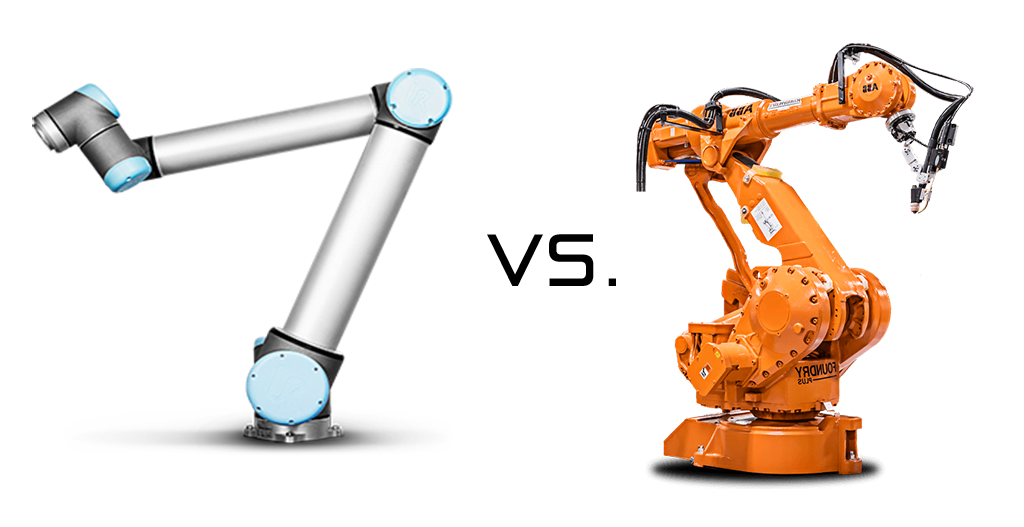

In addition to collaborative features, robots have a few other advantages. Cobots have leveled the playing field for small and medium-sized manufacturers. For decades, large manufacturers have had the advantage of automation by using traditional industrial robots. But these large, expensive and complex robots were designed for high volume and unchanging production processes - as opposed to the low-volume, high-mix production typical of smaller manufacturers.

Collaborative automation has become a versatile, cost-effective and user-friendly technology that allows companies of virtually any size (and any level of technical expertise) to increase productivity, improve quality and respond more quickly to changing customer demands. A good way to address various challenges facing business.

The first cobot was invented in 1996 by J. Edward Colgate and Michael Peshkin. They called the cobot "a device and method for direct physical interaction between a person and a computer-controlled manipulator." Over the years, several cobots have been marketed. Kuka Robotics, which also marketed one of the first industrial robots, released its first cobot, the LBR 3, in 2004. Universal Robots, one of the largest suppliers of robots in the world, released its first cobot, the UR5, in 2008. Four years later, the UR10 was launched, followed by the UR3 in 2015.

The benefits of cobots

Cobots have a few unique features that make automation possible for a wider range of businesses. Check out the benefits of cobots below.

-

Compact

Cobots are small, compact robots and can therefore be used almost anywhere in a production process without taking up too much space.

-

Installing and programming

A cobot is easy to install by anyone and simple to program. With handy apps and software for smartphones and desktops, a cobot is operational in no time.

-

Flexible

-

Mobile

-

Consistent and precise

-

Positive effect on employees

-

Reduction of production costs.

Through the use of cobots, processes are streamlined and production goes up. Ultimately, this leads to a better bottom line.

Impact of cobots on workers

Production work such as packing goods, replenishing stocks or assembly line work is characterized by terms such as "monotonous" and "repetitive" Also, this type of work is often the cause of RSI, Repetitive Strain Injury. A condition caused by performing the same movement often.

By having a robot perform the work of a production worker, the production worker would be able to focus on other tasks. Tasks that require creativity and solution-oriented thinking, such as maintenance or quality control.

Giving workers creative and solution-oriented tasks enriches the work they do and contributes to people's personal development. It also encourages diversity and flexibility, creating an attractive work environment. Factors such as these ensure that employees find more enjoyment in the work they do, become more engaged in the work they do, and become more productive.

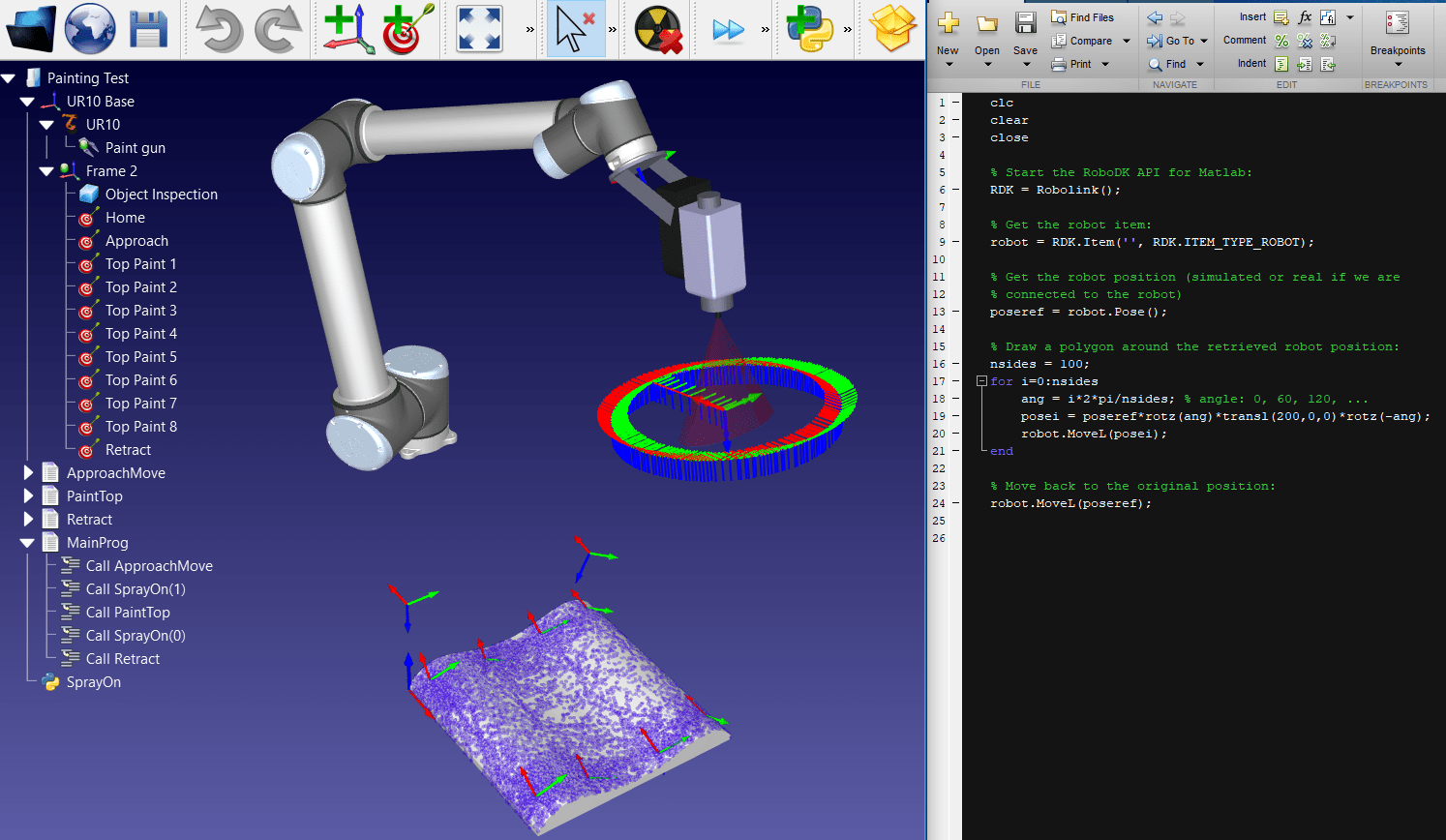

Programming a cobot

Traditional robots require a lot of knowledge and time to program actions and can only perform a few actions. Unlike traditional robots currently used within industry, a cobot is easy to program. Through user-friendly software and mobile applications, cobots can learn new actions. You can also manually move a cobot into desired positions and store them in the software. Because a cobot is so easy to program, they can be quickly implemented into a process and it is even possible to have them perform different tasks.

What are the costs of cobot automation?

Automating processes within manufacturing can have a lot of impact on overall operations. Not only will production efficiency improve, it can also help reduce costs and improve quality. The big question then is; are the costs commensurate with the value that automation can bring? And how does automation compare to other options such as hiring additional staff or outsourcing tasks. So it is important to weigh the costs and benefits beforehand, but what exactly does cobot automation cost?

When selecting an automation solution, cost often plays a vital role for many companies. To accurately assess the total cost, it is crucial to consider two key categories: start-up costs and maintenance costs. The start-up cost refers to all the expenses incurred before the automation system becomes fully operational. This encompasses various factors, such as the cost of materials like the robot, grippers, tooling, frames, sensors, and safety devices. Additionally, it includes the hours spent designing, building, and implementing the system, as well as training operators to use it effectively.

Collaborative robots vs. Industrial robots

Industrial robots and cobots have many similarities, but cobots have some unique features that make them suitable for a much larger audience. Both robots have their advantages and disadvantages. It depends very much on the task and the products to be automated. Industrial robots are suitable for large companies that produce many pieces in a standardized way. Smaller companies can benefit from the flexibility and cost-effectiveness of a cobot. Yet one does not preclude the other. Large companies can also benefit from the advantages of cobots.

Different brands of cobots

Over the years, the number of cobot manufacturers has increased significantly. In total, there are more than 30 companies that focus on the development and production of collaborative robots. The largest of these is Universal Robots. They supply almost half of all cobots worldwide.

Each cobot has its own unique features and specifications. For an automation project, it is therefore important to look at what the requirements are for successful integration. Specifications such as reach, load capacity, accuracy, speed and the number of axes are important pillars in determining whether a cobot is suitable for the application. WiredWorkers works primarily with three brands, Universal Robots, Techman Robot, Fanuc and Franka Emika.

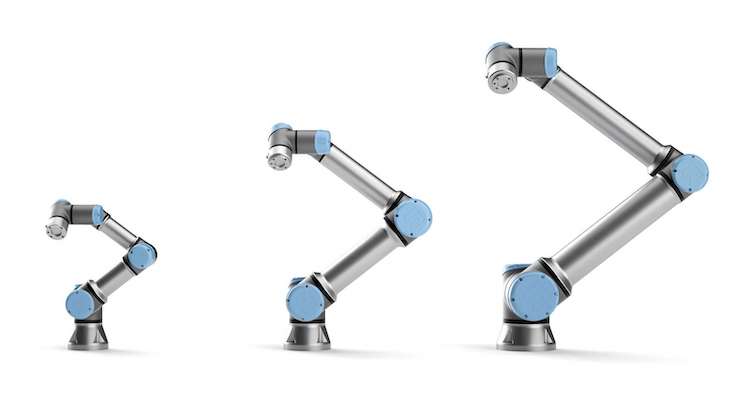

Universal Robots

Universal Robots is the largest cobot manufacturer in the world, with almost half of the market share. In total, they released two different series with a total of 7 different cobots. The CB3 series with the UR3, UR5 and UR10. And the E-series with the UR3e, UR5e, UR10e and UR16e. Differences include greater precision and sensitivity due to a built-in, tool-centric force/torque sensor in the E series. The robots vary in payload and range.

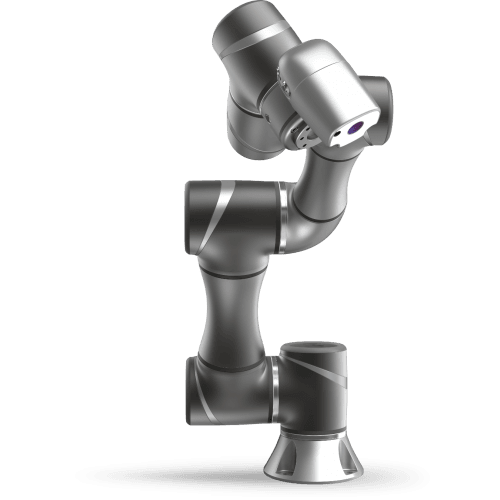

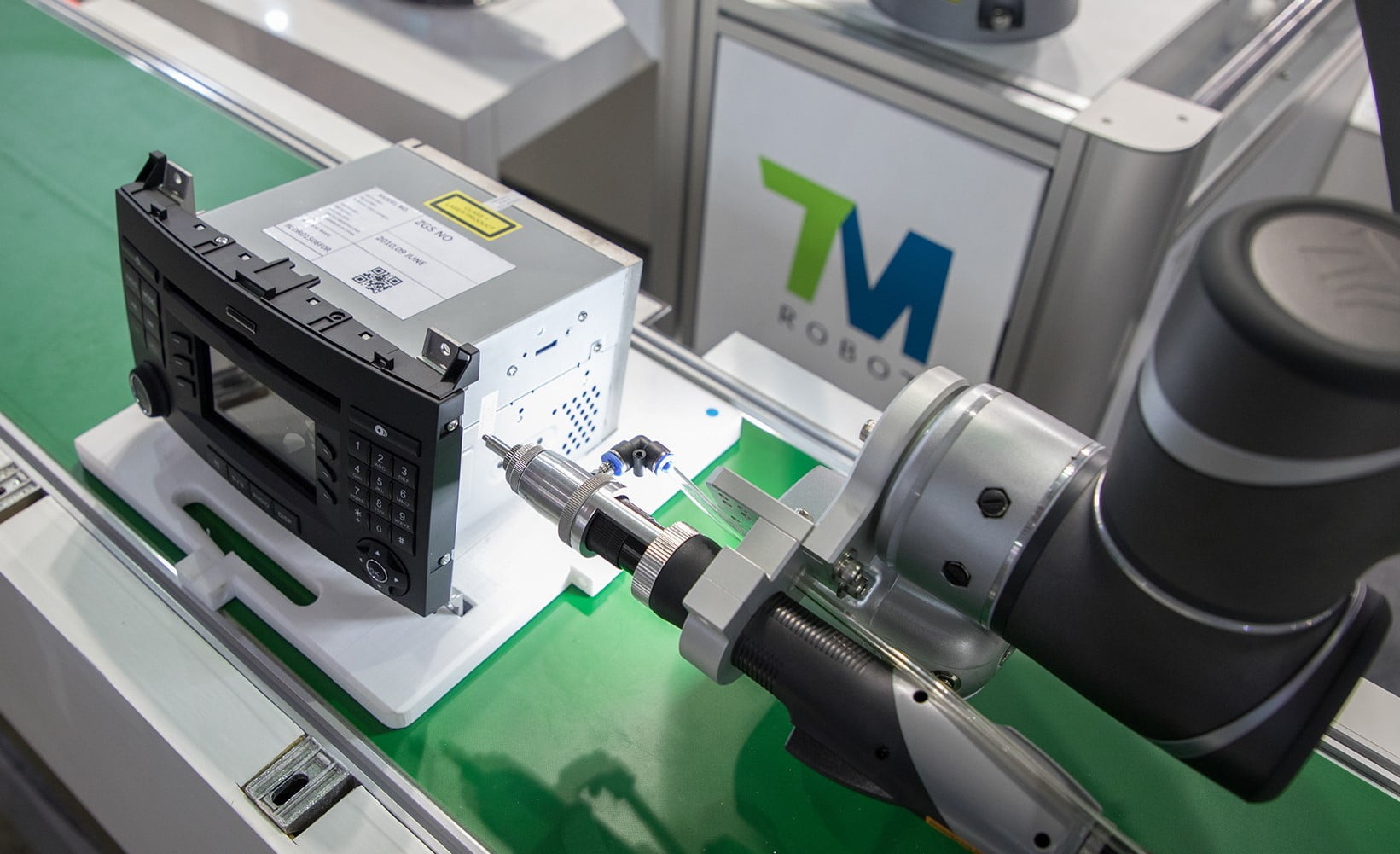

Techman Robot

Techman Robot's cobots are unique in that they have an integrated vision system. A camera is placed on the head of the robot and the accompanying software is equipped with smart vision programs. These include pattern matching, object localization, barcode scanning and color recognition. The software is very accessible, even for people without programming knowledge. With the TM5-700, TM5-900, TM12 and TM14 they have four robots that differ in payload and range.

FANUC

FANUC cobots stand out in the market by providing an extensive array of options, a higher payload capacity, extended reach, and increased speed compared to other cobot series. These collaborative robots are certified for safety, enabling them to seamlessly collaborate with humans and enhance the efficiency of your operations. Whether you run a medium-sized or small-sized business, are new to automation, or operate a large corporation, FANUC's cobot range offers precisely tailored solutions to meet your business requirements.

Franka Emika

Franka Emika's Panda is an advanced robot whose unique feature is its sensitivity and extreme precision. Sensors are placed in the seven joints of this robotic arm, allowing the robot to handle the most delicate objects. The Panda has a range of 850 millimeters and has a payload of 3 kilograms.

Different tools for cobots

Cobots are so flexible because they can be equipped with different tools. Several manufacturers around the world are focusing on developing tools for collaborative robots that allow a cobot to learn new tasks and become even more flexible. The tools can be divided into several categories: Grippers, End of Arm Tooling (EOAT), Vision, Software, Range Extenders, Safety and Supply Systems.

Grippers

Grippers allow the cobot to pick things up and put them down again somewhere else. There are many different types of grippers for a variety of tasks. These include finger grippers, vacuum grippers, and magnetic grippers. Each gripper is suitable for different tasks. For example, soft grippers for food and vacuum grippers for picking up boxes. Grippers also have their own specifications, such as payload, gripping width and gripping force.

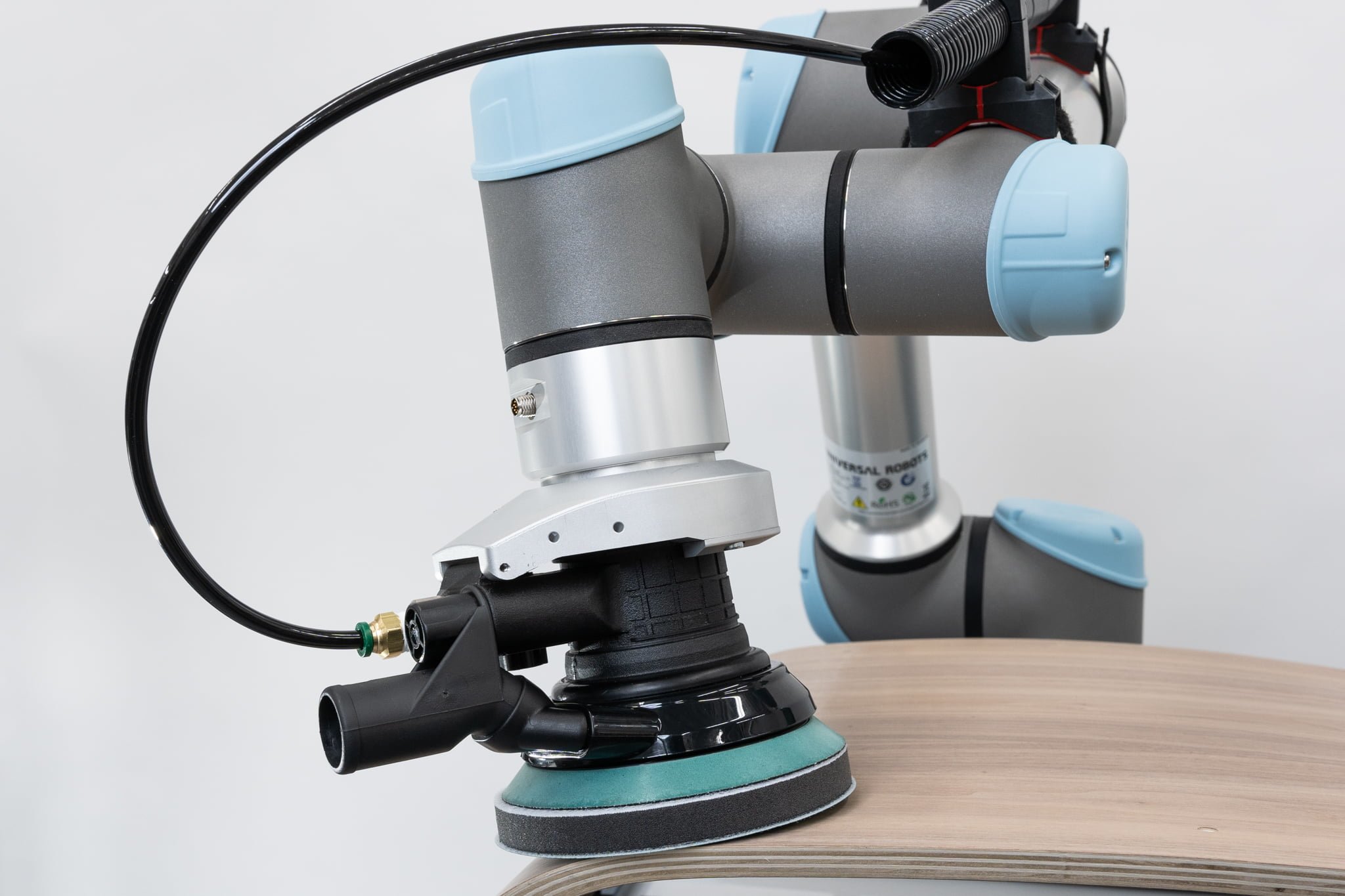

End of Arm Tooling (EOAT)

End of Arm Tooling is a collective word for all kinds of tools that can be mounted to a cobot. For example, glue dispensers, screw machines, sanders, tool changers, sensors and welding and soldering tools. The development of these tools has increased significantly in recent years, so that cobots can help more and more production companies to scale up their production capacity.

Tool changers

To make a cobot extra flexible, there are various automatic tool changers on the market. These tools make it possible for a cobot to change tools completely autonomously, allowing it to perform multiple operations. For example, within an assembly application, one cobot would first use a gripper to place all the parts in the right place, and then use a screwdriver to attach the whole thing. Ultimately, this increases the robot's productivity, generates more output and shortens its ROI.

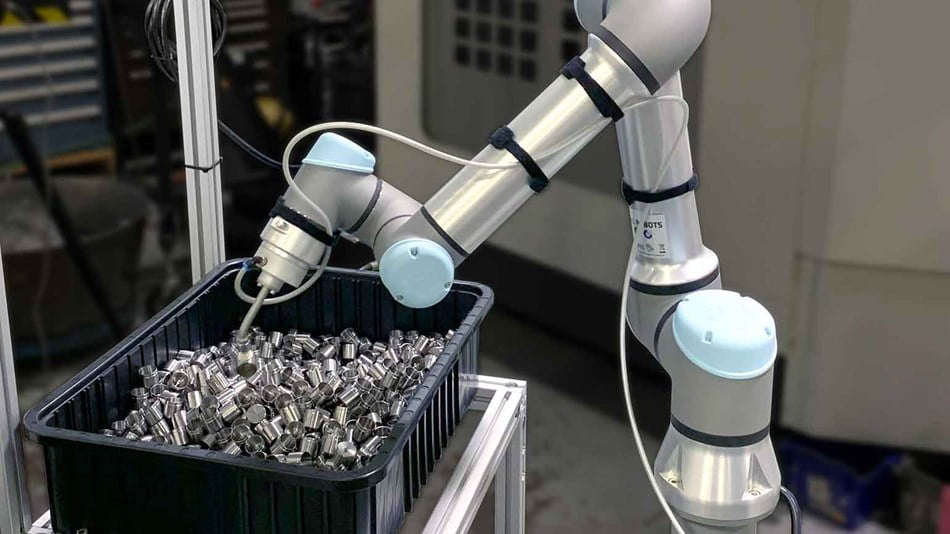

Vision systems

Vision systems give the cobot visibility. With 2D or 3D cameras, collaborative robots can locate objects, scan barcodes and recognize patterns. This brings many benefits, but the biggest advantage has to do with the supply of products. Normally, a cobot needs structured feeds of objects to pick up items. With vision, this is not always necessary because the cobot sees where the product is located.

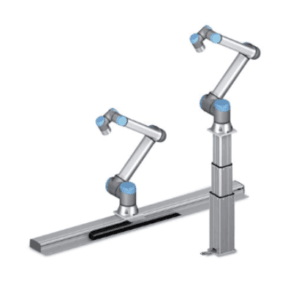

Range Extenders

Range Extenders allow collaborative robots to have more range in the X-axis and/or the Y-axis. For example, a cobot can move back and forth in front of a large machine to perform a task at different points in the process.

Safety

Safety includes all tools that contribute to the safety of the human-cobot cooperation. Think of sensors or screens that detect when someone is getting too close to the robot.

Software

A variety of software is available for programming and designing a collaborative robot application. Each cobot has its own intuitive, user-friendly programming software. In addition, simulator software is available that can be used to design a solid robot integration before proceeding to its actual realization.

Feeding Systems

Feeding Systems involves devices that offer the objects to be handled to the robot. For example, a tool that always puts screws in the same place ready for the robot (and screw machine) to pick up the screws and assemble them into the final product. But also vibrating plates that ensure that accumulated objects are separated from each other again.

Applications of cobots

Thanks to the various tools, user-friendly software and flexibility, cobots are able to perform a variety of tasks. The combination of different capabilities means that an infinite number of actions can be combined into one complete automation application. In theory, a cobot can learn anything. In practice, there are several applications that recur most often, as below.

Sanding and polishing

Polishing, deburring or sanding requires a controlled action. Thanks to built-in sensors, a cobot can follow any contour while applying a constant force to the surface. This enables the cobot to deliver consistent quality. Perfect for wood, stainless steel or metal surfaces.

Screwing

Simple, repetitive screwing tasks are perfect for a cobot. With the right tools and software, the robot can easily be programmed to align the object with a hole, place parts precisely and use the same force continuously. Something that is impossible for humans but that a cobot can easily sustain for 40 hours a week.

Pick and place

Pick and place is very simply picking up and moving objects. For example, picking parts from a bin and sorting them on a assembly line. Pick and place applications are very simple in the basics, but as more tools are required it becomes more complicated. For example with a sensitive gripper, double gripper or objects with different dimensions.

Bin picking

Bin picking is comparable to pick-and-place, only here the objects are not delivered in a standardized way. Thanks to smart software and vision technology, the cobot recognizes objects in a bin and picks them up one by one. Useful for supplying a conveyor belt, for example.

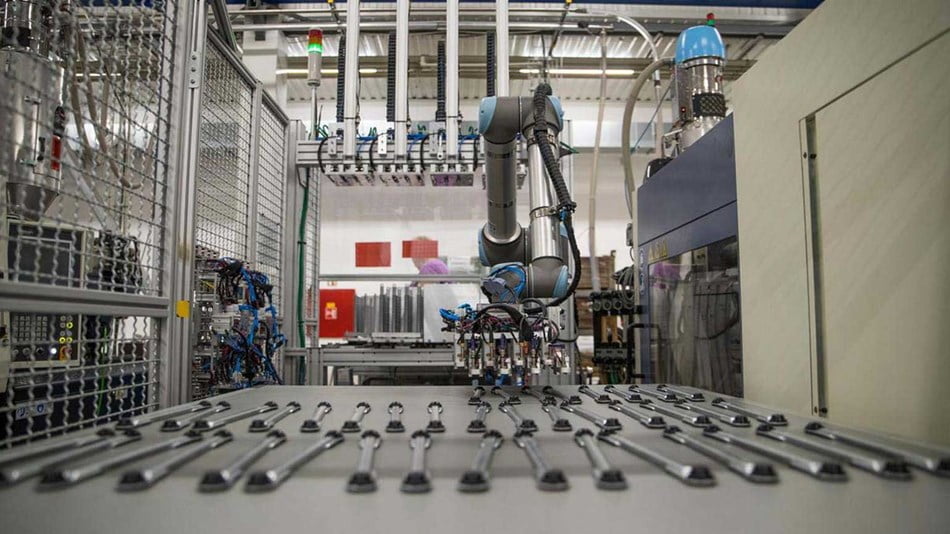

Machine tending

Machine tending is the placing of parts in for example a CNC lathe or bending machine. While the robot does its work, human operators are free. This improves worker safety and frees them up for higher-level tasks. It also improves productivity and production can continue after normal working hours for greater output and business flexibility.

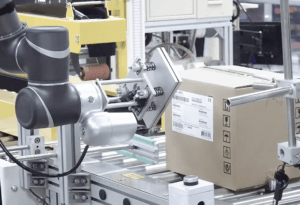

Palletizing

Palletizing (stacking boxes on pallets) can be set up more efficiently with collaborative robots, bringing many benefits. Boxes are picked up with electric vacuum grippers and placed on pallets. New technologies eliminate the need for an external air supply and hoses, which facilitates integration, reduces costs, and creates less noise and causation. Besides palletizing, of course, a cobot can also depalletize.

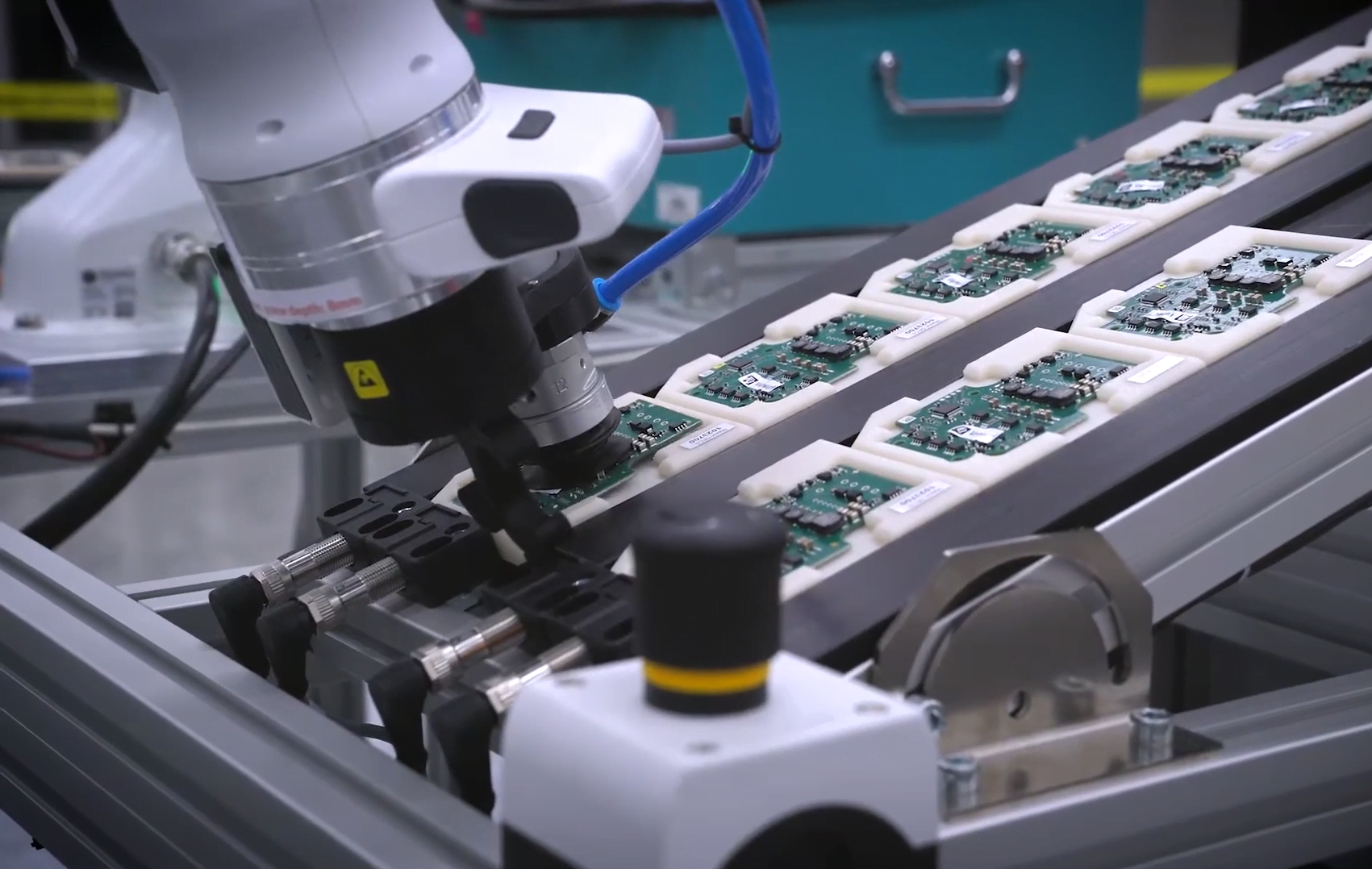

Quality testing and inspection

Cobots can come in handy for quality testing and inspection in a variety of industries. For example, a robot can place objects in a testing device and then sort them. Think about circuit boards or samples in a laboratory. Thanks to vision technology, there are also opportunities for a cobot to perform visual inspection. A good way to improve production quality inspection.

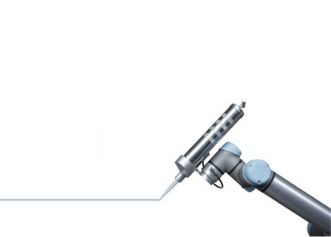

Gluing and sealing

Gluing and sealing are excellent tasks for a cobot. A sealant or glue syringe is mounted on the end of the cobot. The cobot moves along the desired path and evenly dispenses the adhesive or sealant.

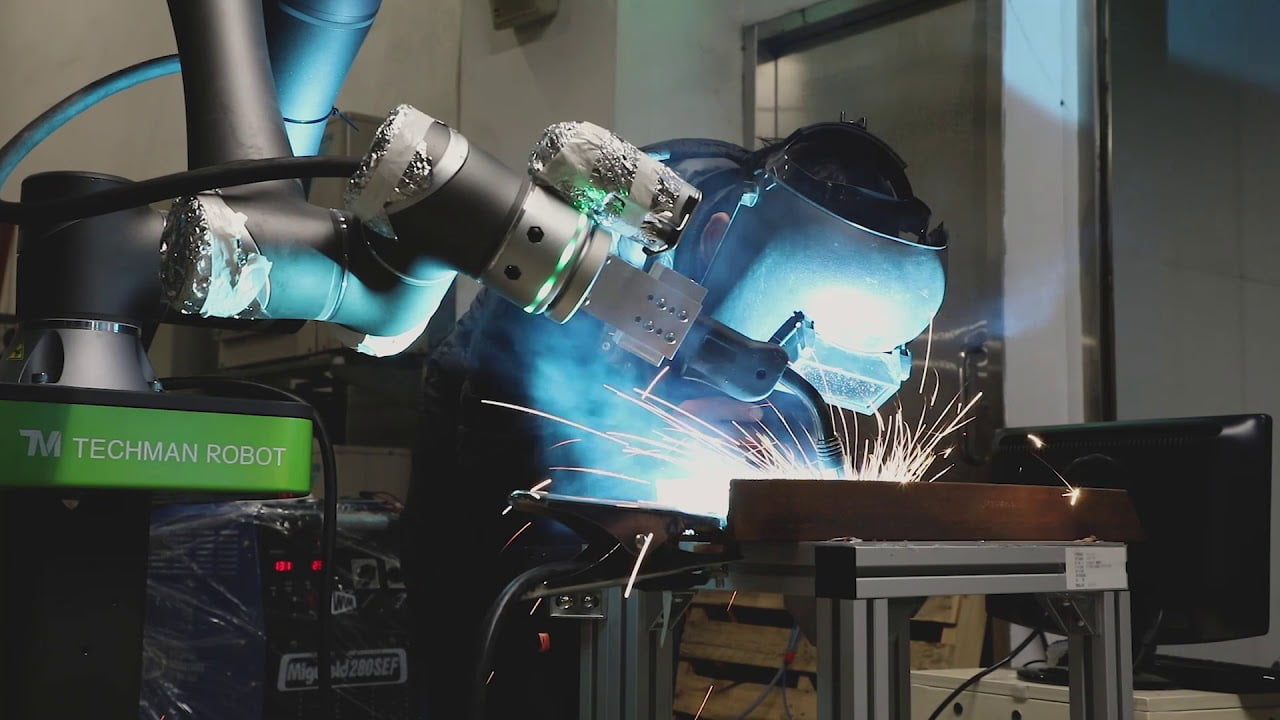

Welding

Welding is a task that must be performed with the utmost precision and welding with cobots brings many benefits. Cobots are more precise than humans and will therefore deliver more consistent quality. Cobots can weld in a variety of applications. Think Mig/Mag, Tig, spot welding, arc welding, ultrasonic welding and plasma welding.

Soldering

Soldering is a precision job that can be perfectly automated with a collaborative robot. Cobots are extremely precise, more accurate than humans, and thus deliver consistent quality. Cobots can do both soldering and brazing.

Different industries for cobots

Thanks to their flexibility and the fact that you can teach a collaborative robot anything, they can be used anywhere. There are several industries where cobots are ideally suited and have already been successfully integrated.

Food industry

The demand for automation within the food industry has increased in recent years. Several reasons such as increasing demand, stricter food safety and worker safety are a cause of this. For the food industry, automation is more complex than other industries because it is difficult for robots to handle food products directly. The advent of cobots and new gripper technology has changed this.

Plastics industry

The plastics industry is characterized by high-mix low-volume production. In other words, a large variety of products in small quantities. This type of production process is difficult to automate because the production process often changes. Collaborative robots have changed this because they are easy to convert and can learn new operations.

Packaging industry

Within the packaging industry, there is increasing demand for smaller series and more customization. Cobots can respond to this perfectly. Tasks that a cobot can perform are simple packing tasks, such as placing products in boxes. In addition, cobots are perfect for stacking boxes on pallets. Tasks within the packaging industry are often physically demanding and repetitive. By relieving employees of these, productivity increases and employees become happier in their jobs.

Electronics industry

The electronics industry often works with small products that need to be handled carefully. Collaborative robots are equipped with various sensors, which makes them 'sensitive robots', as it were. Therefore, they are extremely suitable for working with these kinds of products. Cobots can thus be used to automate a testing process or quality control.

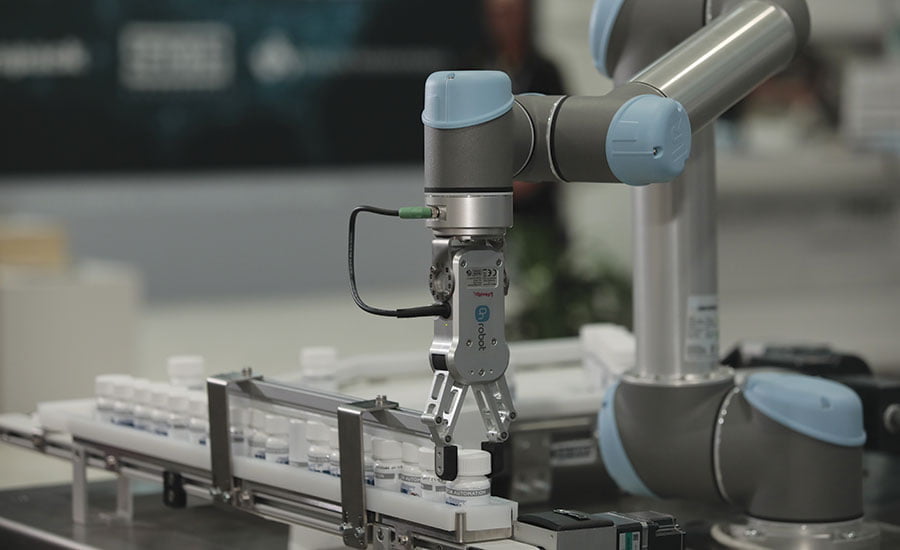

Pharmaceutical industry

The pharmaceutical industry often works with large quantities and good inspection is of great importance. It is also important that the margin of error is as low as possible. These kinds of characteristics make this industry perfect for automation. The larger the production quantities, the more advantageous it is to automate. And because robots do the same operation frequently and accurately, the chance of errors is also minimized.

Automotive industry

The automotive industry has benefited from automation with robots for years. Large industrial robots have been used to assemble cars for years. Developments such as small series sizes and an increasing demand for customization mean that collaborative robots have also become interesting for this industry.

Metal industry

Also, in the metal industry high-mix low-volume production is increasingly common. A large variety of products in small numbers. This type of production environment is perfect for collaborative robots, because cobots can be quickly converted when the production demands it. Tasks that cobots could perform within the metal industry are welding, soldering or loading CNC machines and press brakes.