Franka Production 3

Franka Production 3

Franka Production 3 is the robot with human touch and dexterity. An industrial system that increases productivity for anyone who needs industrial robotics automation.

Payload »

3 KG

Radius »

855 MM

Weight »

18 KG

Joints »

7 DOF

Download the Franka Production 3 specifications!

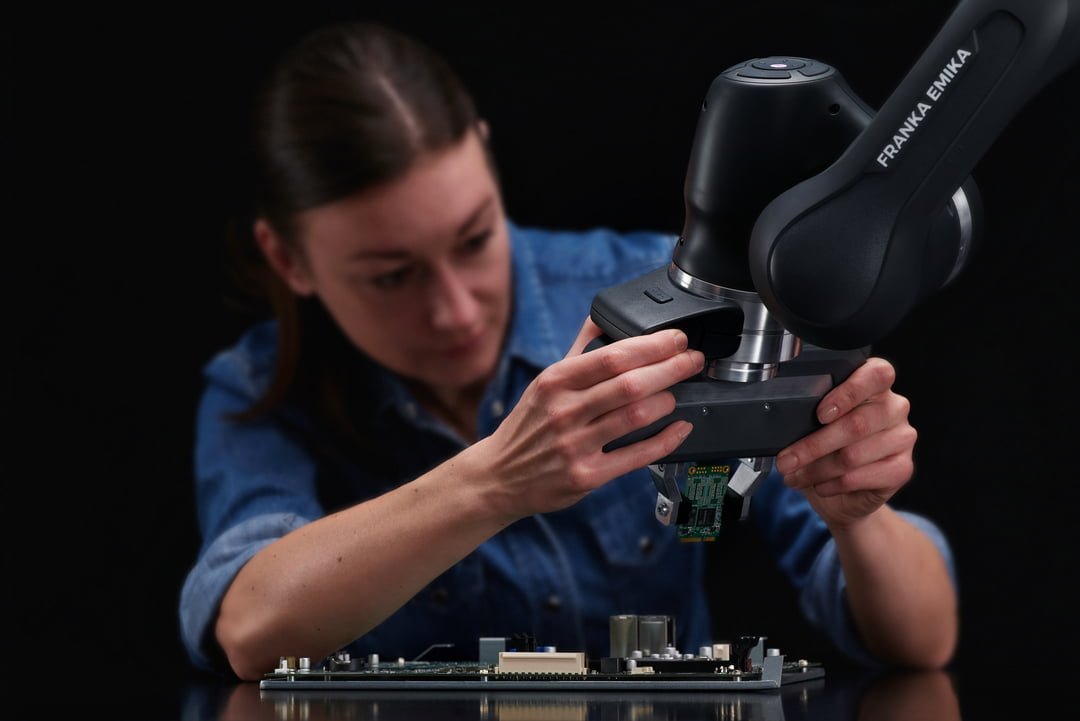

Human arm-like dexterity

The dexterity of a human arm makes the robot suitable for sensitive operations and force applications. This robot is equipped with more than a hundred different types of sensors, including in-house designed, industry-leading torsion sensors in all 7 axes. Unique in its ability to mimic human-like and dexterity-based skills.

Designed to be easy

Designed with intuitive ease of use in mind. Installation is straightforward, hand control is effortless, interaction is smooth. And with our powerful intuitive interfaces, no prior programming knowledge is required. Anyone can become a robot expert and turn their process knowledge into robot automation.

Little expertise required

Apps and the Store allow existing operations to be learned quickly and intuitively by the cobot. Due to the ease of installation and operation, no special team of robot experts is required, resulting in significantly more flexibility in production and less training for staff. In addition, App Workflows enable rapid reconfiguration of tasks, making it easy and fast to respond to the demands of dynamic factories.

The robotic automation tool for everyone

Compliant behavior

Adapts accurately and reliably to surfaces and environments

Adaptive assembly

Engineered with human-like skillset

Robust processes

Handle inconsistencies easily and use force control for quality assurance

Plug-and-use

From delivery to first usage in under 30 minutes

Apps, your building blocks

Easiest, most efficient workflow-based programming

Franka App Store

Easy access to Apps

Franka World

After the succesful introduction of the Franka Emika Panda, the German company has continued work on a new digital robotics platform called Franka World. With this software they want to 'connect the digital world with the physical world'.

Franka World makes it possible for researchers, partners, customer, developers and suppliers to communicate with each other. In addition, it provides access to products, services and the management of complete cobot fleets.

Download the Franka Production 3 brochure!

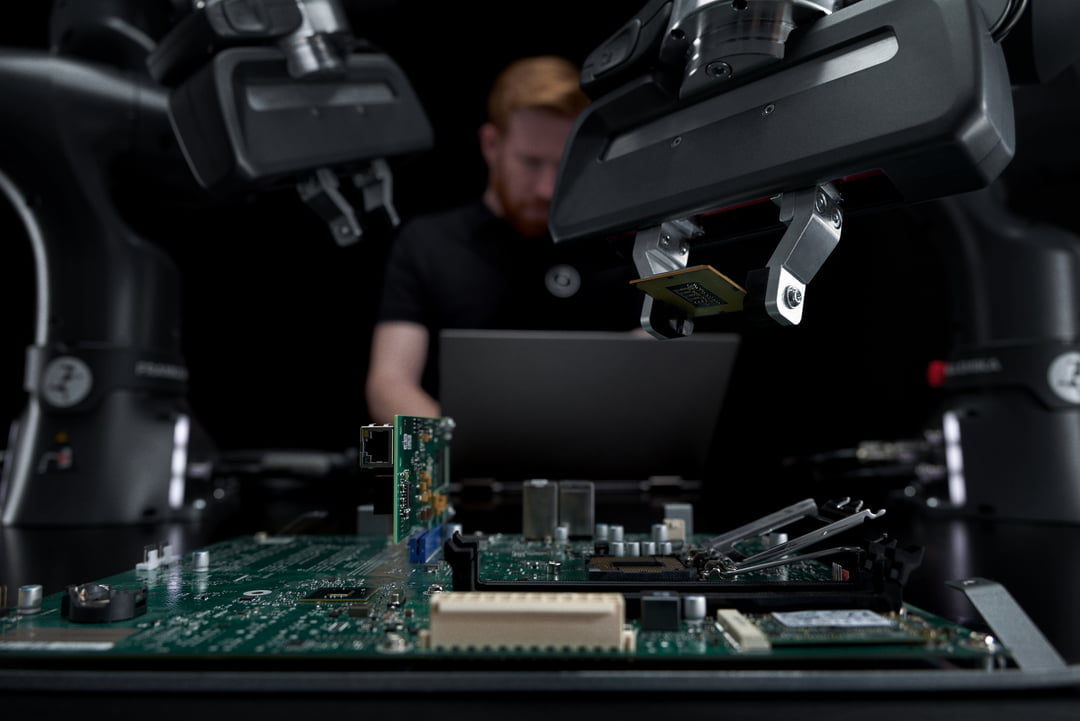

Production 3 skills

Ultra-sensitiveness to contact forces thanks to in-house designed, industry-leading torque sensors in all 7 axes. Their excellent resolution, accuracy and repeatability enable dynamic sensing of the environment and exceed the performance of most purpose-built force sensors. The robot can apply slight forces to perform tasks such as joining, inserting and screwing. Continuous and accurate fine tuning of forces is also a requirement for applications such as contour tracking, polishing and grinding.

Elegant combination of industrial-grade revolutionary sensing and industrial-grade position control. Additionally to the force sensing capabilities, the robot also features the characteristics of a classic rigid industrial robot with a pose repeatability of < +/- 0.1 mm (ISO 9283) mm and negligible path deviation even at high velocities. This enables precise, robust and fast execution of manufacturing processes.

Within its workspace, it can reach and operate far-off (855 mm) as well as very close to its own base, and the geometry of the 7 axes allows for complex poses to reach difficult spaces, allowing execution of processes even in confined environments.

Adjustable guiding modes compensate gravity and friction to reduce the perceived weight up to a factor of 60, ensuring smooth and elegant interaction between human and machine. And the Pilot interface is conveniently at hand on the robot Arm, allowing for remote control of the user interface. Besides, our sophisticated sensors, control algorithms and internal model allow prompt detection and reaction upon unwanted collisions within milliseconds.

Franka Emika robots incorporate highest mechatronic integration. It is equipped with more than a hundred sensors of various types, including in-house designed, industry-leading torque sensors in all 7 axes, as well as high resolution position sensors, brushless DC motors, strain wave gears and cross roller bearings.