Collaborative robots in automative industry

Collaborative robots, or cobots, are advanced industrial robots designed to work safely and efficiently with humans. In the automotive industry, cobots have been gaining ground in recent years because of their flexibility and ability to work in close cooperation with human workers. In this article, we discuss the benefits and applications of cobots in the automotive industry.

Advantages of cobots in the automotive industry

One of the main advantages of cobots is their ability to complement human labor, increasing the productivity and efficiency of production processes. By deploying cobots, companies can speed up their production processes and increase output while maintaining product quality. In addition, cobots can help improve worker safety by taking over repetitive and dangerous tasks from them.

Applications of cobots in the automotive industry

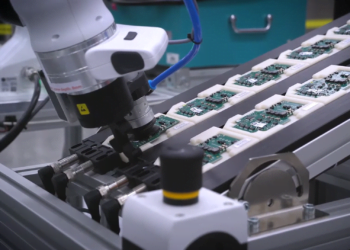

Assembly

Assembly, such as screwing is a simple and monotous, repetitive task that demands a lot of workers, and which is simple to automat with a cobot.

Packaging

Palletizing and packaging can be simpler, faster and more efficiently with a cobot. By automating palletizing of your products, you lighten the work of your employees.

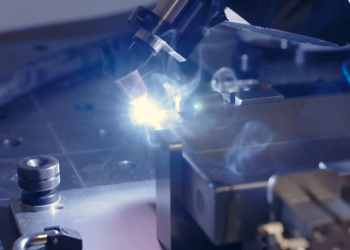

Welding

Welding is a task that must be performed with the utmost precision. Cobots are more precise than humans and will therefore deliver more consistent quality.