Collaborative robots in metal industry

Collaborative robots, also known as cobots, are cutting-edge industrial robots that have been specifically designed to operate safely and productively alongside human workers. In the metal industry, cobots have been increasingly popular due to their adaptability and capacity to collaborate closely with human operators. This article examines the advantages and uses of cobots in the metal industry.

Advantages of cobots in the metal industry

Cobots offer a significant advantage in the metal industry by enhancing human labor and boosting productivity and efficiency in production processes. The integration of cobots into metal manufacturing can accelerate production and amplify output, all while ensuring consistent product quality. Moreover, cobots can alleviate worker safety concerns by taking over repetitive and hazardous tasks.

Assembly

Assembly, such as screwing is a simple and monotous, repetitive task that demands a lot of workers, and which is simple to automat with a cobot.

Packaging

Palletizing and packaging can be simpler, faster and more efficiently with a cobot. By automating palletizing of your products, you lighten the work of your employees.

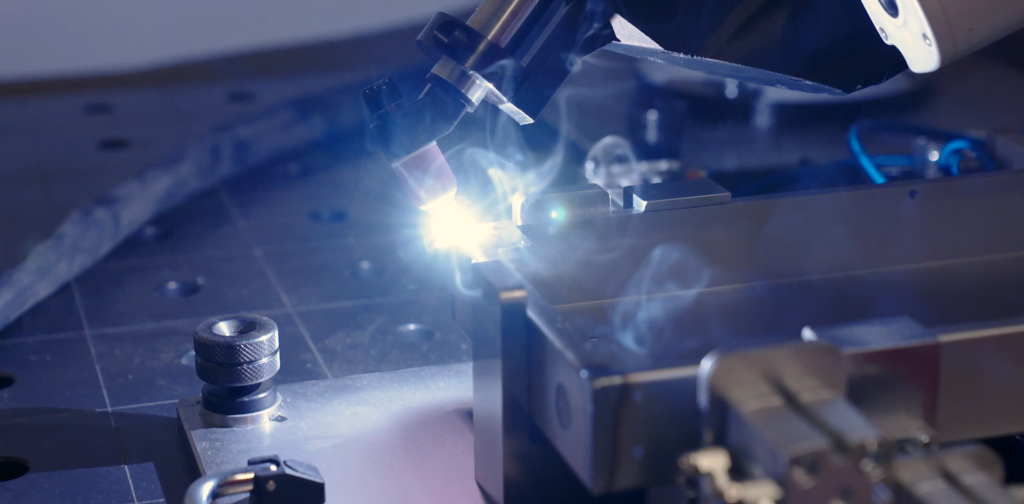

Welding

Welding is a task that must be performed with the utmost precision. Cobots are more precise than humans and will therefore deliver more consistent quality.