Collaborative robots in the pharmaceutical industry

In pharmaceutical laboratory settings, collaborative robots, also known as cobots, are advanced robotic devices designed to work efficiently and collaboratively with human workers. Cobots have gained popularity in the pharmaceutical industry due to their flexibility and ability to work closely with human operators. In this article, we will discuss the benefits and applications of cobots in pharmaceutical laboratory environments.

Advantages of cobots in the pharmaceutical industry

One of the key advantages of cobots in the pharmaceutical industry is their ability to complement human labor, improving the productivity and efficiency of production processes. By integrating cobots into their operations, pharmaceutical companies can accelerate production and increase output, while maintaining strict product quality standards. Additionally, cobots can enhance worker safety by taking on repetitive and dangerous tasks that could pose a risk to human workers.

Applications of cobots in the pharmaceutical industry

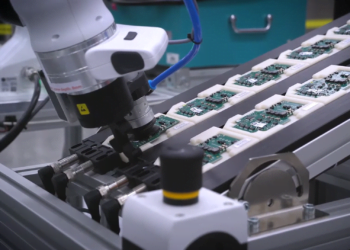

Cobots are widely utilized in the pharmaceutical industry for various tasks, including assembly, packaging, and quality control. Due to their adaptability, cobots can be quickly programmed to handle different tasks, allowing them to operate across multiple production lines and with various products. Additionally, cobots can be outfitted with sensors and cameras, enabling them to take precise measurements and conduct quality checks during the production process.

Other industries...

- « Previous

- 1

- 2

- 3

- Next »