End-of-arm-tooling for collaborative robots

End of Arm Tooling is a collective word for all kinds of tools that can be mounted to a cobot. For example, glue dispensers, screw machines, sanders, tool changers, sensors and welding and soldering tools. The development of these tools has increased significantly in recent years, enabling cobots to help more and more manufacturing companies to scale up production capacity.

Different types of end-of-arm tooling

Thanks to EOAT, there are a lot of possibilities to teach the robot new applications. The development of these tools is not standing still, which means that in the future more and more applications can be performed by a cobot. Below is a selection of the various tools.

Glue dispensers

A dispenser is used to mount a sealant or glue syringe on the end of the robot. This allows a cobot to travel a desired path and distribute glue or sealant very precisely and evenly. Thus, there is little product loss because you can set exactly how much glue or sealant is needed.

Screwing Machines

Screwing machines allow cobots to assemble products autonomously or in collaboration with an operator. Screwing is a monotonous, repetitive task that can be boring and mind-numbing for humans. A cobot, in combination with a screw machine can easily keep up this task for long periods of time and is also super accurate.

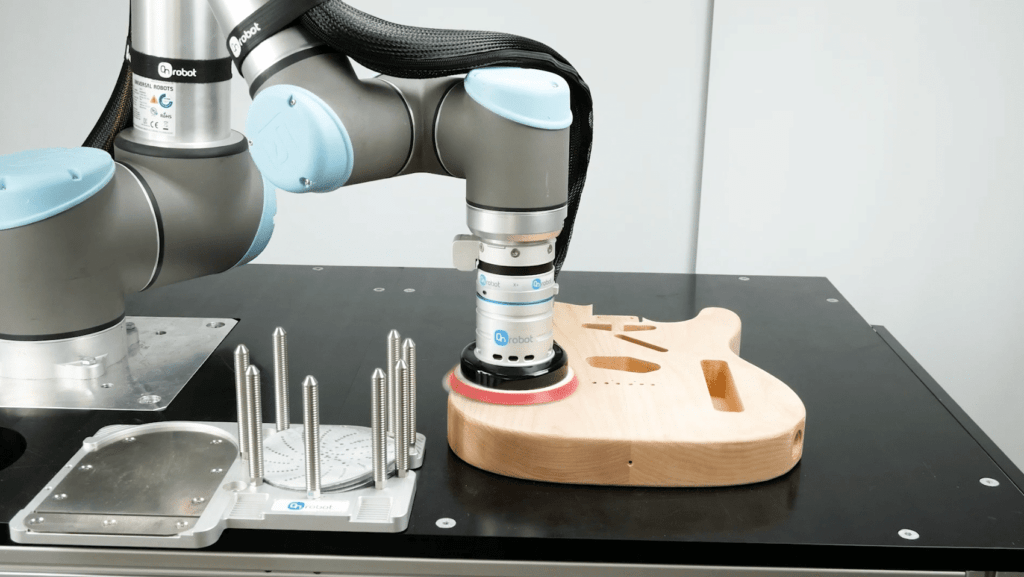

Sanders

With a sander at the end of the robot, a cobot can polish, sand or deburr surfaces. The built-in sensors also ensure that the robot will always do this with exactly the same force which ensures consistent quality. With the user-friendly software, you teach the robot to follow a path quickly and easily.

Sensors

Collaborative robots have sensors built into them by default to make the robot sensitive and collaborative. But sometimes you may need additional sensors because a task requires higher sensitivity. External force torque sensors are available for this purpose.

Easy to integrate

End-of-arm tooling for collaborative robots is characterized by ease of use and quick installation. They can be connected and connected quickly and easily. Thanks to user-friendly software, communication with the robot is also easy to set up.