What is industrial automation?

Industrial automation is the optimization of production processes by having human actions performed by machines and computers. This makes processes more efficient and increases production.

Thanks to industrial automation, the quality and flexibility of the production process are optimized. People are also relieved of heavy, repetitive work and have their hands free to do useful work elsewhere in the process. In addition, the error rate is reduced, the quality of production improves and employees become happier in their jobs.

In many industries there is currently a shortage of personnel to meet the demand in the market. It is therefore necessary for many companies to innovate. Developments such as 'Industry 4.0' and the Internet of Things are making it increasingly attractive and easy to automate and connect different machines, software and processes together.

Benefits of industrial automation

Reduces operating costs

There are numerous reasons why automation helps to reduce operating costs. Personnel costs are reduced, a reduced error rate provides cost savings, and by being more productive, the cost of production per piece also reduces significantly.

Increased productivity

Higher quality

Industrial automation reduces the margin of error, which results in higher quality. In addition, it results in products of uniform quality, as processes are made more efficient and the repeatability of operations is increased.

Safety

What does industrial automation mean for workers?

Production work is, in most cases, repetitive, mind-numbing or heavy work. In addition to being unchallenging for people and therefore difficult to concentrate on for long periods of time, it can also cause injuries. Performing the same movement for long periods of time is often the cause of RSI and heavy work can cause other complaints.

This type of work is easy to automate precisely because it is so repetitive. On the other hand, workers can focus on quality work because they have space and time left over for other things. Tasks that require more creativity and solution-oriented thinking, such as maintenance or quality control.

Doing creative, solution-oriented work has many benefits for employees. People develop on a personal level and the employees' work environment becomes more attractive. All this together makes employees enjoy their work more, therefore become more engaged, which in turn results in higher quality production.

Industrial automation and IT

Industrial automation and IT are two different things, but current technological developments are bringing these two fields closer and closer together. Industrial automation is mainly about controlling movements and industrial installations. IT is mainly about organizational processes. With the development around Smart Industry (Industrie 4.0), the collaboration between industrial automation and IT has increased significantly. By integrating smart solutions in industry, more and more data is collected, which is useful for controlling organizational processes (IT).

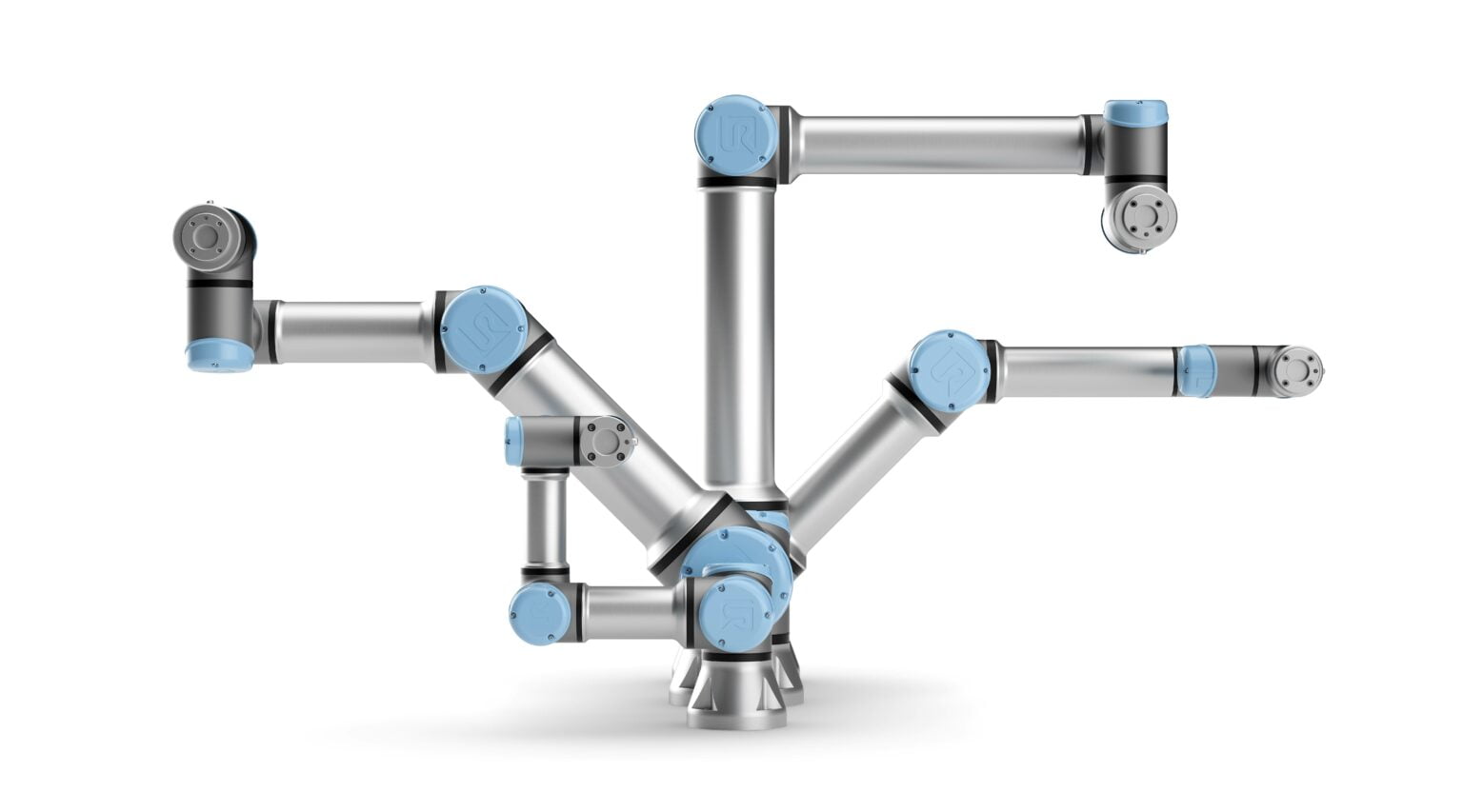

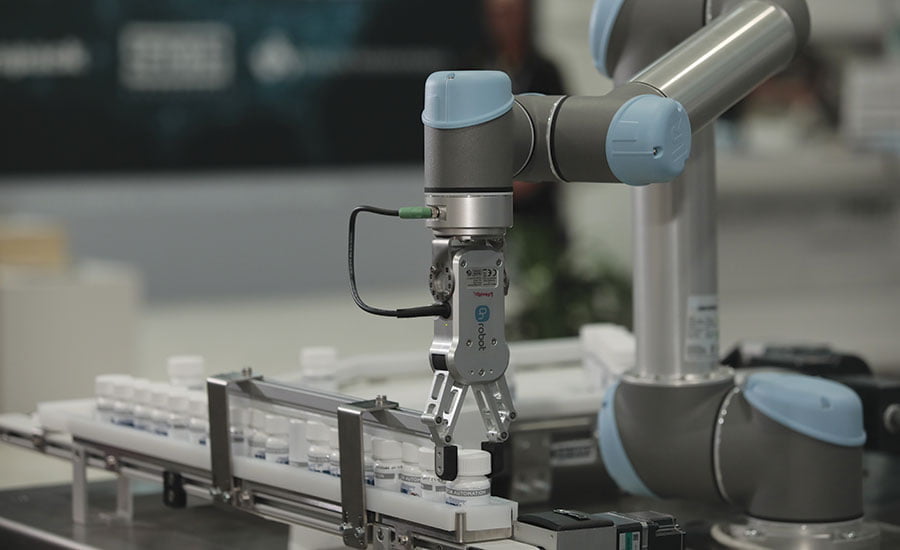

Industrial automation with collaborative robots

One of the developments coming out of the Smart Industry developments are collaborative robots. These are robots that can collaborate with people in a safe way. This is because they are equipped with sensors that sense whether they are being interrupted in their movements. This allows them, after extensive risk analysis, to work near people. This is in contrast to traditional industrial robots. In addition, they tend to be somewhat lower in purchase cost and the programming software is very user-friendly. Because they are so easy to program, it is also possible to have them perform new tasks quickly. Perfect for increasing productivity quickly and relatively cheaply and for responding more quickly to changing market demand.

Industrial automation applications

Basically, there are countless possibilities when it comes to industrial automation. The combination of different robots and tools makes the possibilities endless. There are a number of tasks that are often automated.

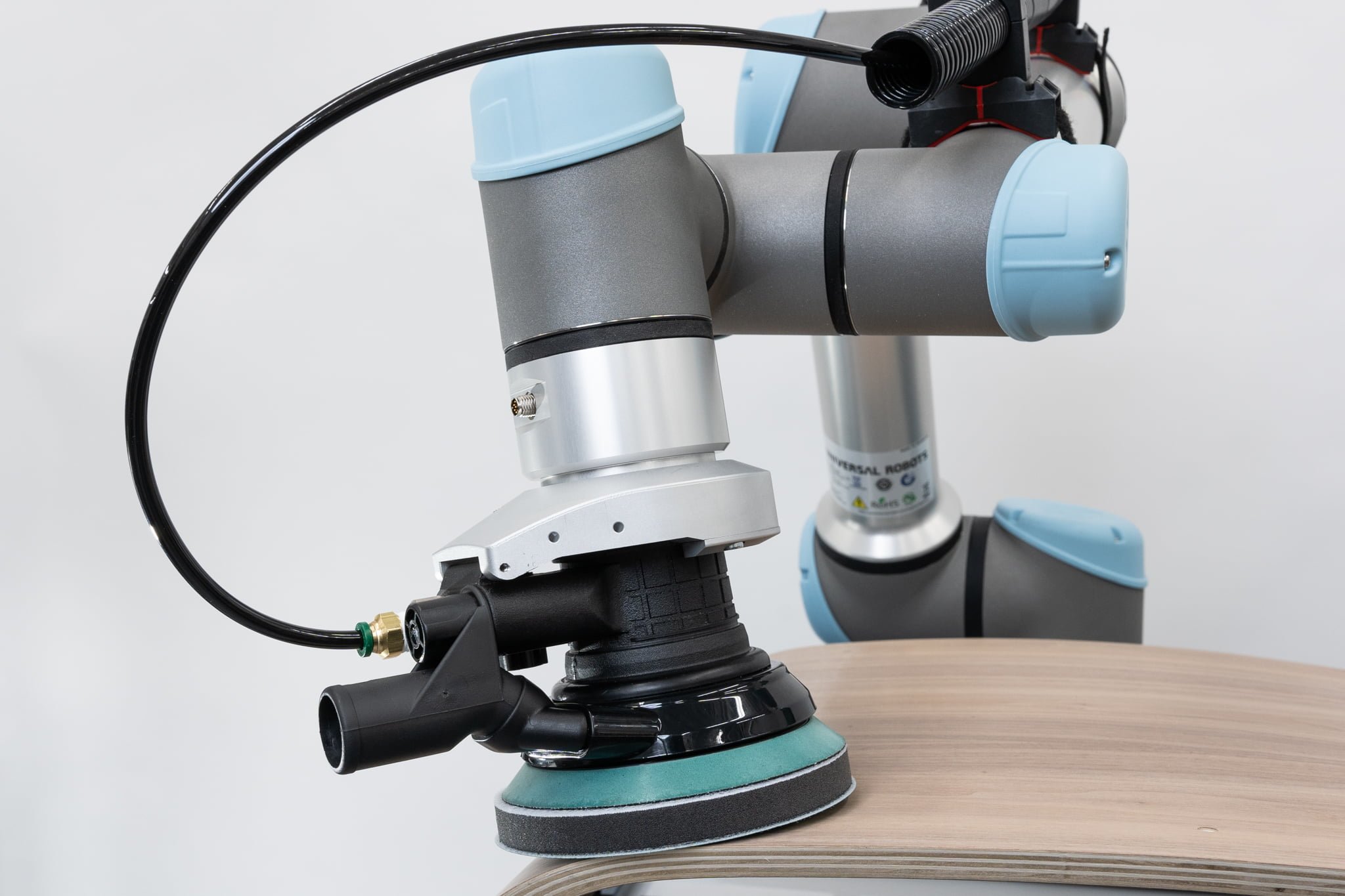

Sanding and polishing

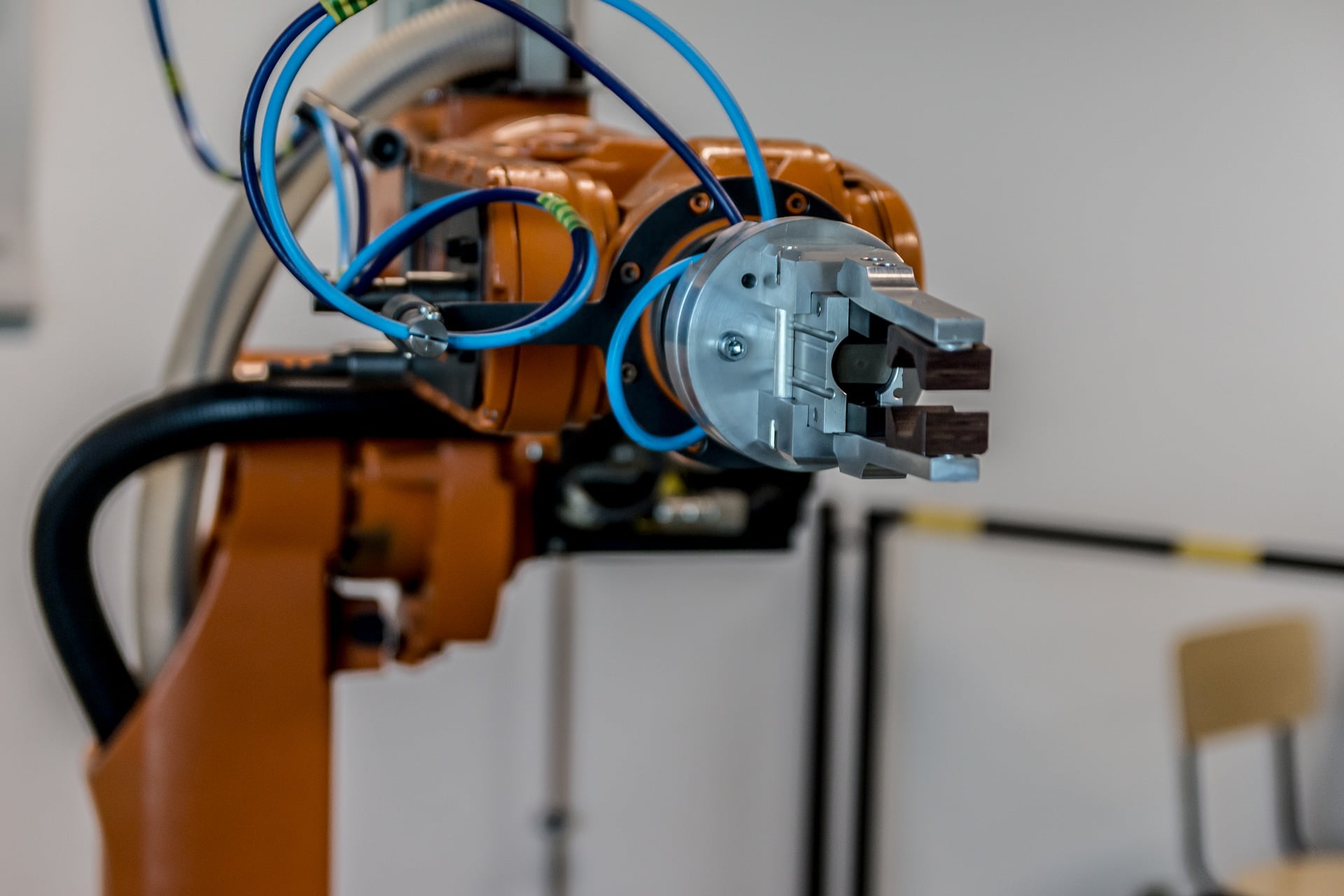

Sanding, deburring or polishing are tasks that must be performed in a controlled manner for the best results. Robots are able to perform this task with the greatest precision and deliver consistent products.

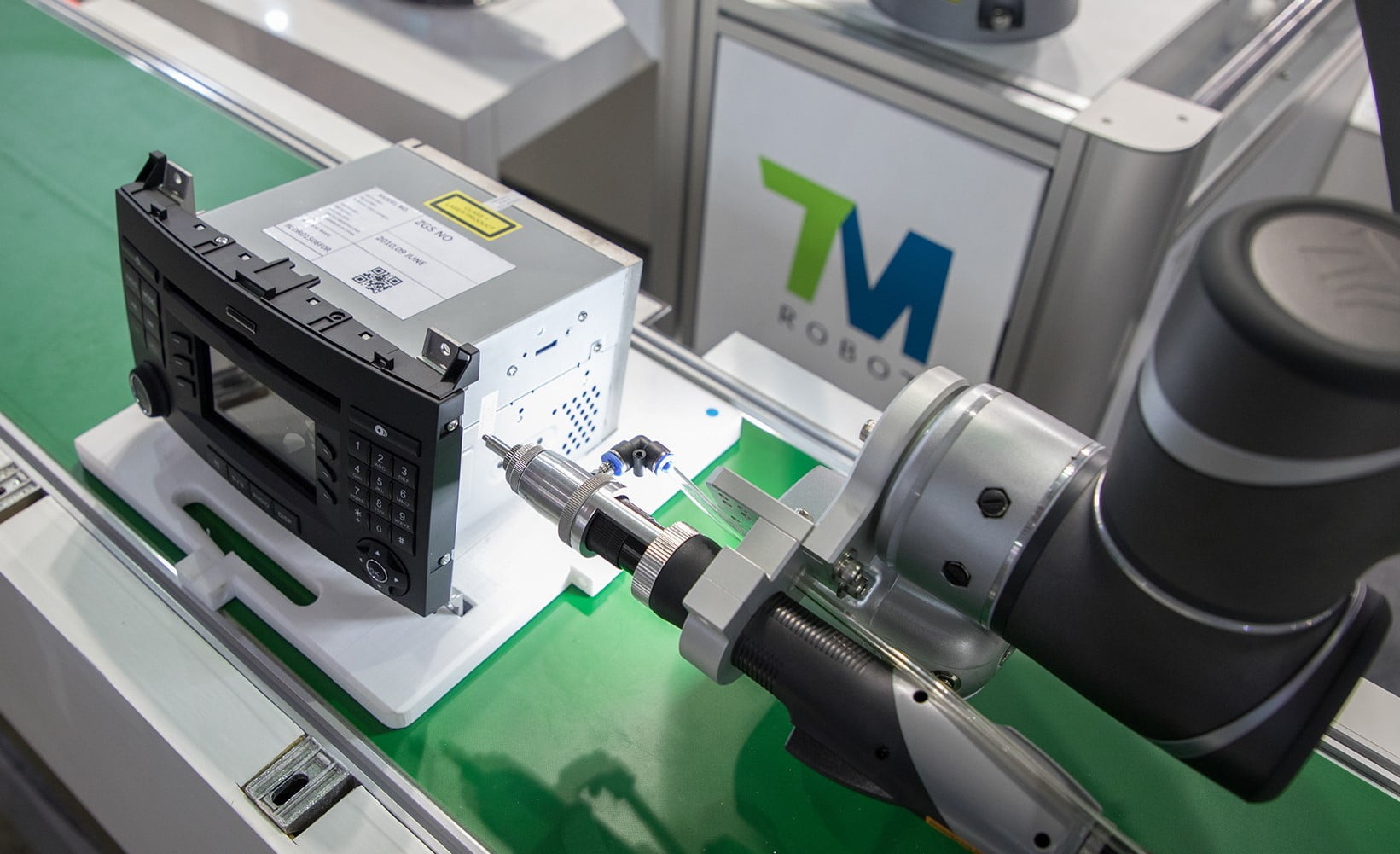

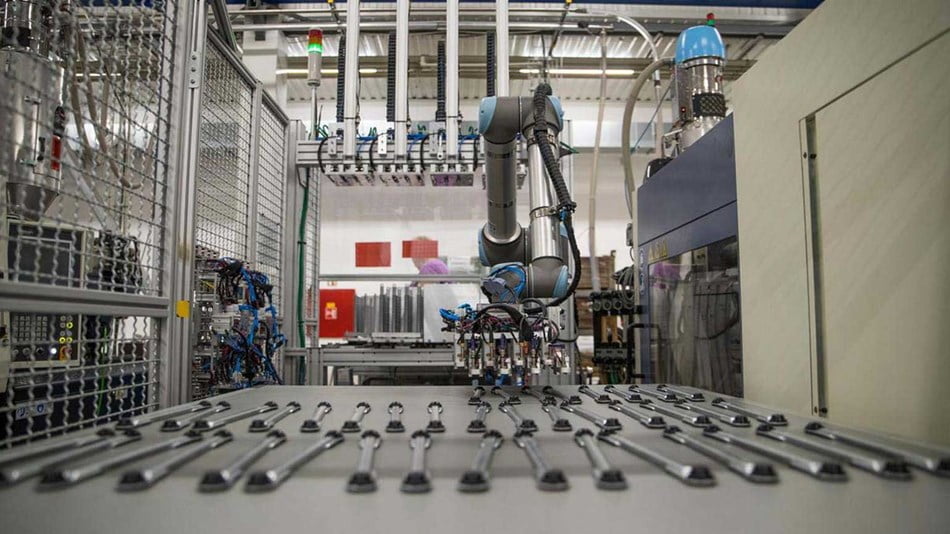

Screwing

Simple, repetitive screwing tasks are very easy to automate. For humans, it is a boring, mind-numbing task that is almost impossible to perform with concentration day in and day out. Robots, on the other hand, can do this all day, without pause and always with the same strength and precision.

Pick and place

Almost every automation task is essentially a pick and place task. The robot grabs something and puts it somewhere else. For example, placing products in machines or on a conveyor belt. In the basics, it is simple to set up a pick and place task, but the more variety of products or the supply of products, the more complicated it becomes.

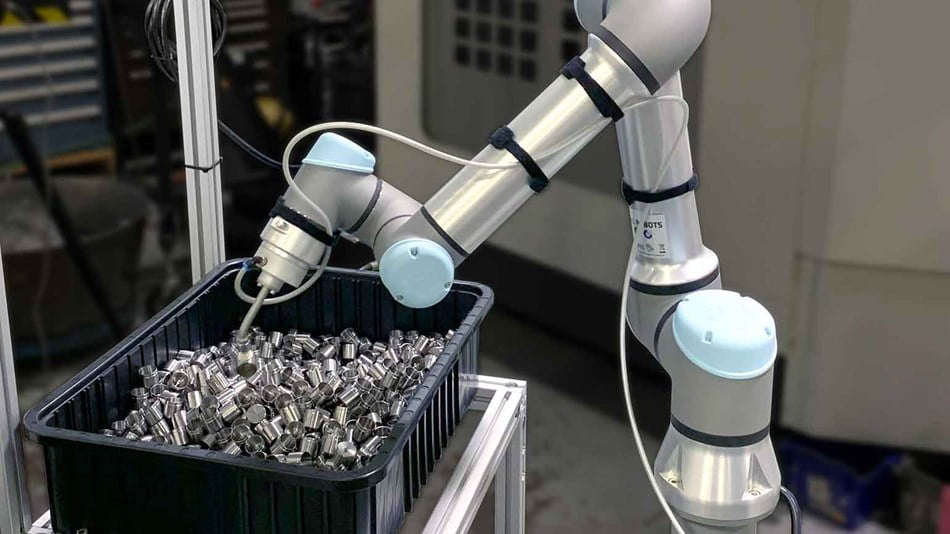

Bin picking

Bin picking is a pick-and-place task where the objects are not delivered in a standardized way. With the help of vision systems and smart software, the robot recognizes where the objects are and can pick them up one by one from a bin, for example.

Machine tending

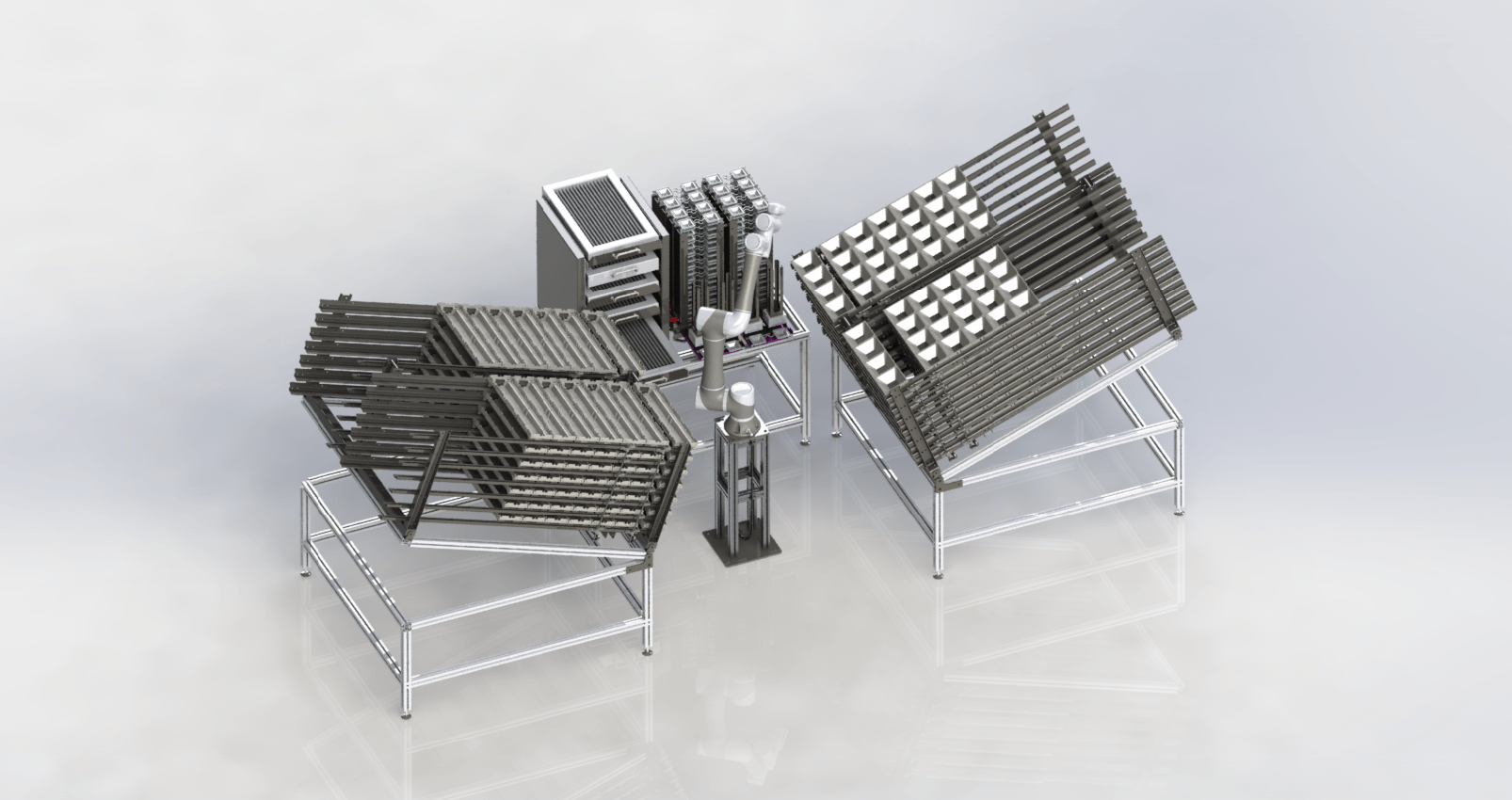

Machine tending is nothing less than loading a machine, for example a CNC lathe or a press brake. A task that is still frequently performed by operators today, while it is fundamentally a simple task to automate. Automating machine loading is not only good for productivity, it also ensures more output outside of normal working hours, as robots can work longer hours.

Palletizing

Stacking boxes on pallets is often an arduous task for individuals. In addition, it is fairly easy to automate because boxes need to be stacked in a structured way and because they are often presented in a standardized way. Thanks to new technologies, vacuum grippers can pick up these boxes without external air supply and associated hoses.

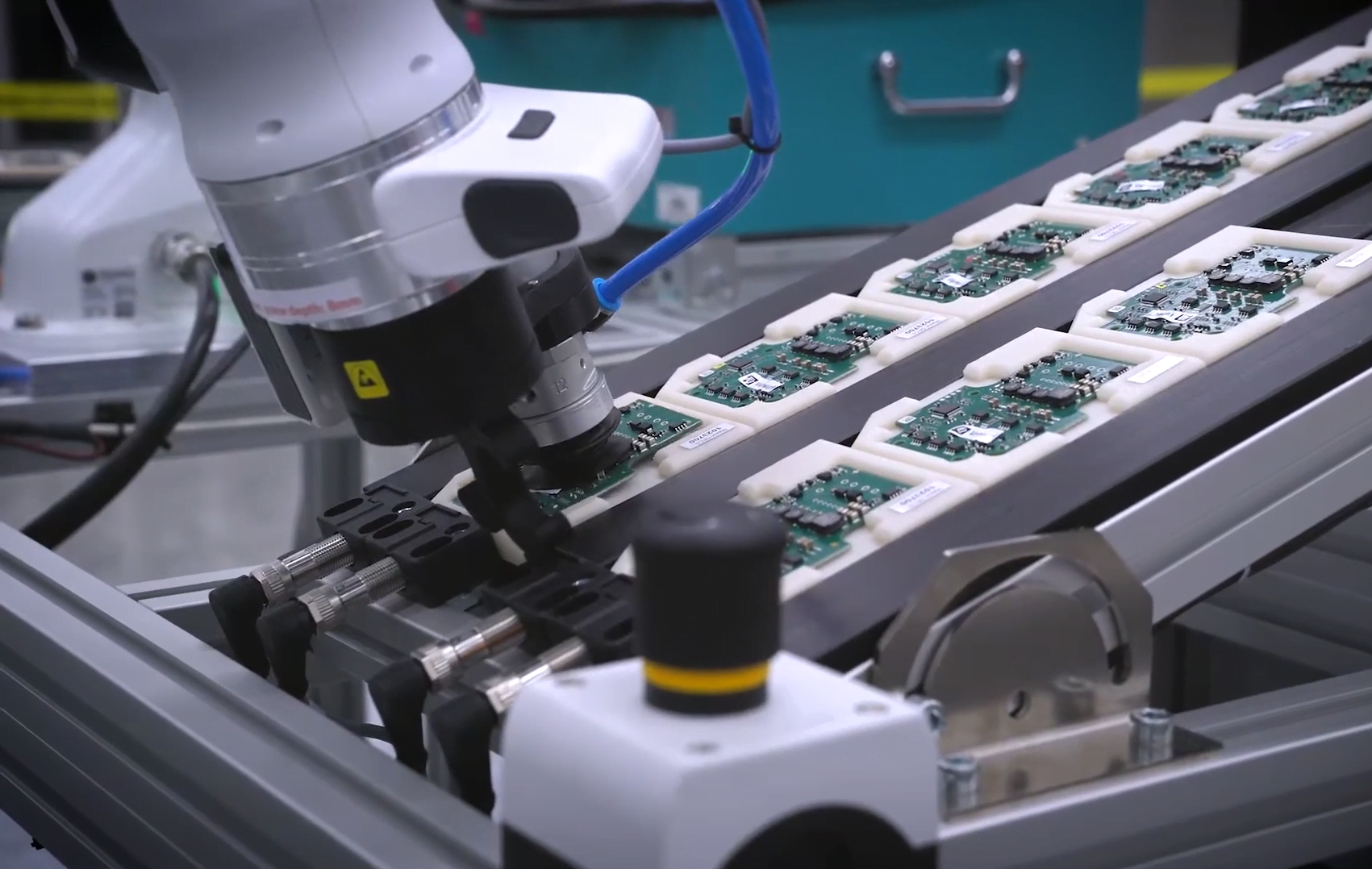

Quality testing and inspection

Quality testing and inspection occur in almost every industry, and there are several ways to automate this. For example, a robot can place products in a testing device and then sort them. Thanks to several new vision technologies, it is also possible to automate optical inspection.

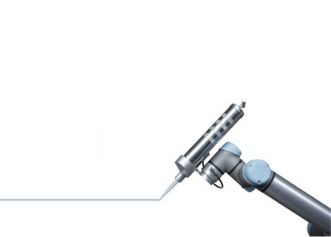

Gluing and sealing

Glue and sealants are great tasks to automate. A sealant or glue syringe is mounted on the end of the cobot, the robot moves along the desired path and evenly distributes the glue or sealant.

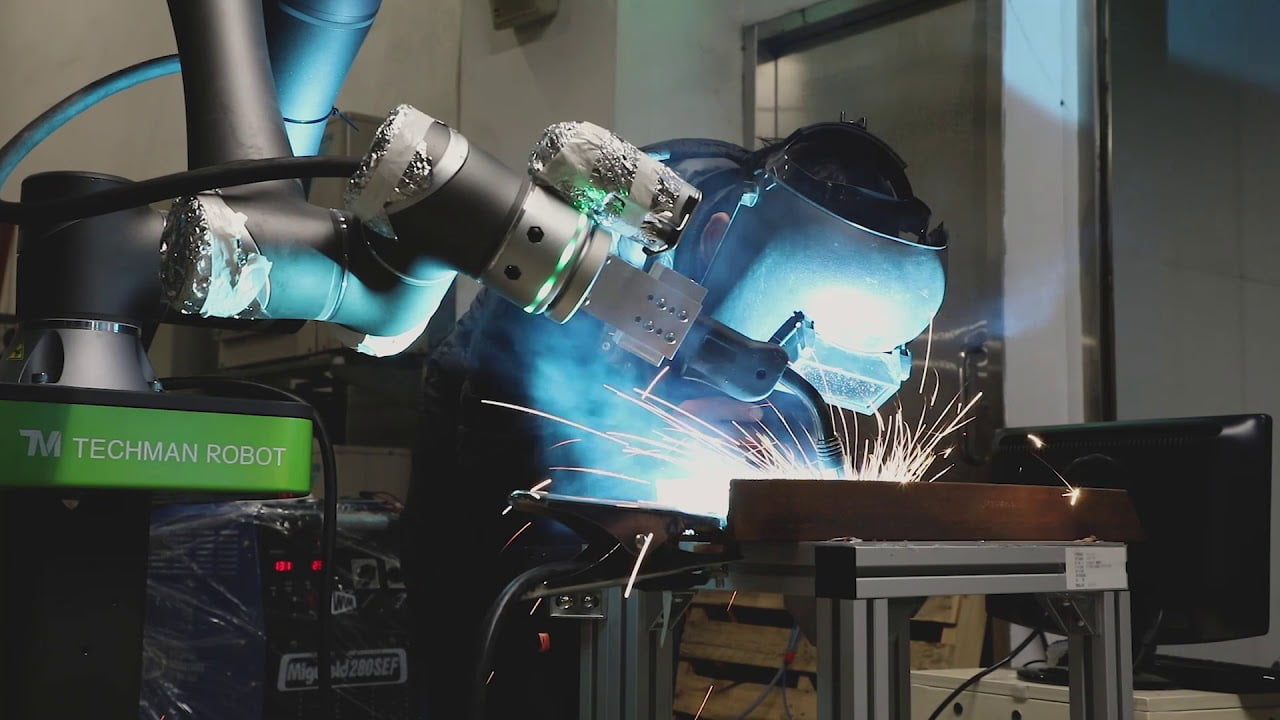

Welding

Welding robots have been used in various industries for years. They are more precise than humans and therefore deliver more consistent quality. There are different applications in which a welding robot can weld, think Mig/Mag, Tig, spot welding, arc welding, ultrasonic welding and plasma welding.

Soldering

Soldering is precision work and can therefore be of better quality if it is automated. Robots are in fact more precise than people and deliver consistent quality. Robots can both braze and solder.

Suitable industries for automation with robots

Food industry

Within the food industry, automation has been on the rise in recent years. Increasing consumer demand, increasingly stringent food safety and worker safety have contributed to this. Automation within the food industry is more complex than in other industries because food items are often fragile and more difficult to handle directly. In addition, hygiene is an important factor. The advent of cobots and new gripper technology, among others, has made things easier.

Plastics industry

Within the plastics industry, high-mix low-volume production is often used, meaning that there is a wide variety of products and they are produced in small numbers. This is often difficult to automate because the production process changes frequently. The versatility of collaborative robots and developments within Smart Industry have changed this.

Packaging industry

Tasks within the packaging industry often involve packing operations, such as packing boxes or placing boxes on pallets for transportation. These are typically repetitive tasks that require little creativity or are physically demanding of employees because the packages are often heavy. Perfect for automating, relieving workers and increasing productivity.

Electronics industry

The electronics industry works with small products, such as chips and PCBs. These are then often automatically tested, inspected or even soldered. Small, fragile products that need to be handled carefully. Collaborative robots that work with the most advanced sensors are ideally suited for this.

Pharmaceutical industry

The pharmaceutical industry is characterized by large quantities and the lowest possible margin of error. Therefore, inspection is of great importance. These characteristics therefore make it the ideal industry for automation. The large quantities make it economical and easy to automate, and because robots are highly accurate, the chances of error become minimal.

Automotive industry

The automotive industry is one of the first industries to get started with automation. Large industrial robots have been used for years to assemble complete cars. Developments such as small series sizes and an increasing demand for customization mean that Smart Industry developments have also become interesting for this industry.

Metal industry

In the metal industry, the demand for customized and custom-made products has also continued to increase. Thanks to the advent of new technologies, such as collaborative robots and Smart Industry, this can be well automated. Tasks that are automated within this industry are welding, soldering or loading CNC machines and press brakes.