Production automation is essential for manufacturing companies that want to be competitive and future-proof in the digital world. At WiredWorkers, we ensure that the selected production system is reliable and offers optimal efficiency, quality and durability. Although implementing the right system is an investment, it leads to cost savings and strengthens your position against competitors.

WiredWorkers approach

Each system has unique features that enhance the process. We begin by exploring different concepts, compile the desired goal, and determine specifications based on this. We weigh pros and cons, considering external conditions, and finally deliver a simple reliable concept. Details of the machine are carefully worked out for the optimal result.

Various applications of production automation

WiredWorkers' systems can be applied to various aspects, including pick and place, orientation, transportation, assembly, labeling, control, coding, machining, dispensing, positioning and more. Consider technical automation, warehouse automation and process automation within your company.

Production automation with cobots

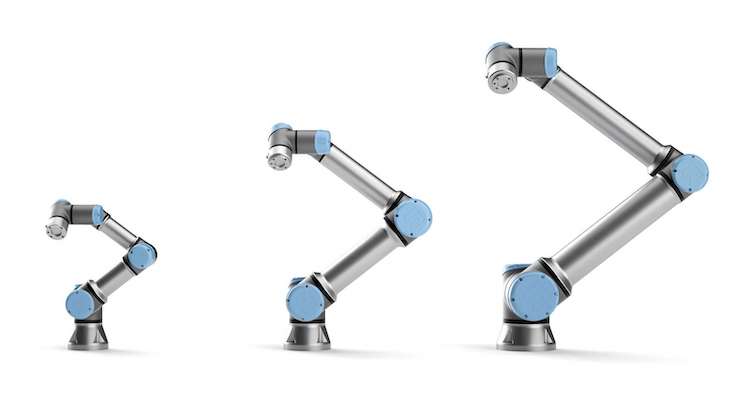

In the world of production automation, WiredWorkers goes beyond designing specialized machines; we are also experts in cobot integration. This innovative technology sets us apart from traditional automation options. Equipped with advanced sensors, cobots, unlike industrial robots, have a degree of sensitivity to their environment, allowing them to work safely with humans with minimal risk of accidents. When an obstacle is detected, the cobot automatically pauses its activities, ensuring safety at all times.

Regarding production automation with cobots, the programming process also has its advantages. Unlike traditional robots, which require considerable time and expertise to program, cobots can be programmed quickly and easily with user-friendly software or mobile apps. Their versatility allows them to be seamlessly adapted to a wide range of tasks, while their mobility adds another layer of flexibility. For companies in the manufacturing industry with low production volumes and diverse production lines, cobots offer an ideal solution that meets their unique requirements.

By choosing production automation with cobots, companies can benefit from improved efficiency, increased flexibility and significantly reduced risk of workplace accidents. With advanced sensor technology, cobots can interact accurately and safely with human operators, leading to an overall increase in productivity.

Installation of systems

At WiredWorkers, system installation is a crucial component. We ensure that ongoing processes are not disrupted and consider material selection, working conditions, hygiene requirements and any use of chemicals. Together, we draw up a suitable schedule to carefully integrate the system into your production process.

Benefits of production automation

- Increased labor productivity

- Reduced labor costs

- Alleviation of labor shortages

- Reduction of manual tasks

- Optimization of safety

- Improvement in quality

- Reduction of production lead time

- Completion of tasks that cannot be performed by humans

WiredWorkers, production automation specialist

At WiredWorkers, we specialize in comprehensive production automation solutions, guiding companies through the entire "cobotization" journey. Our process begins with a meticulous analysis of your business processes, uncovering bottlenecks and identifying optimal areas where cobots can maximize efficiency. With a focus on fostering a trusted collaboration between employees and robot colleagues, WiredWorkers offers comprehensive cobot training programs.

Would you like to learn more about production automation? Then contact us directly for a no-obligation consultation.