A smart, advanced robotic arm

Cobots are the newest players in the robot field. Thanks to some unique features of these robots, automation is coming within reach of a wider range of companies. Conventional industrial robotics techniques prevented companies with small batch sizes, little in-house robot knowledge or little physical space from taking advantage of the benefits of robotic automation. Cobots have changed this.

Cobots are mobile, lightweight, compact robots that are very easy to program. Thanks to their mobility, they can be used in different places in production and do not have to perform the same task 40 hours a week. Of course they can!

In addition to mobility, a cobot also has flexibility. Thanks to the user-friendly software, it is very easy to teach a robot tasks. You don't have to be a robot expert to do this and it can be done very easily with a smartphone, laptop or tablet. SMEs dealing with high-mix, low volume production can more easily start automating thanks to these developments. The robot can add value during peaks at different places in production.

We have already briefly mentioned that a cobot can also work together with people. A cobot is equipped with various sensors and therefore 'feels' when it is stopped or interrupted. It will then stop immediately. Industrial robots do not do this and are still protected by fences for this reason. Cobots are safer and, depending on the tooling used, people can work safely alongside a cobot.

Different brands of robotic arms

WiredWorkers is brand independent and has a wide range of robotic arms and tooling, each with their own unique features. The combination of the right cobot with the right tooling makes it possible to automate almost any task. The most commonly used cobots are those from Universal Robots, Techman Robot and Franka Emika.

Franka Emika

Franka Emika's Production 3 is the robot with human touch and dexterity. An industrial system that increases productivity for anyone who needs industrial robotics automation. The dexterity of a human arm makes the robot suitable for sensitive operations and force applications. This robotic arm is equipped with more than a hundred different types of sensors, including in-house designed, industry-leading torsion sensors in all 7 axes. Unique in its ability to mimic human-like and dexterity-based skills.

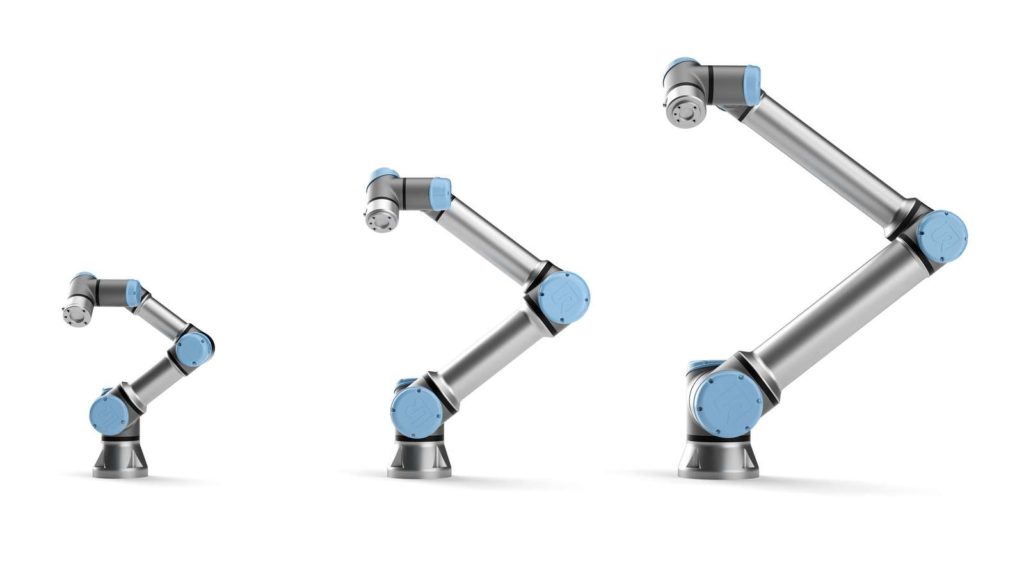

Universal Robots

Universal Robots are robust cobots made for heavier work. With the UR3, UR5, UR10, UR16 and UR20, Universal Robots has a wide range of cobots with variable payloads and ranges. With that, they offer a suitable solution for every challenge.

Techman Robot

Techman's collaborative robotic arms are the first cobots on the market with integrated vision. Both hardware and software systems are integrated, as well as various standard robot vision functions. Think pattern matching, object localization, barcode scanning and color recognition. Thanks to the user-friendly user interface, it is accessible to everyone to use this cobot.

In addition to the integrated vision functions, Techman Robot's robots are characterized by a particularly high degree of accuracy. The robots are accurate to within 0.5 mm, making them suitable for the most sensitive tasks.

Robotic arm installation and maintenance

WiredWorkers installs, programs and maintains your robotic arm. After an analysis of the company and its working methods, it looks at where the cobot can be used and how these tasks can standardize and improve processes. Thanks to the development of software and hardware, the programmable robot can take on different functions. The ultimate goal of cobotization is to ensure that workers are supported or relieved and that processes are optimized to improve quality. To ensure that employees embrace and become familiar with their robot colleague, WiredWorkers provides cobot training.