Our method of operation

To provide a fully functioning, customized automation solution, we take the following steps.

Introduction

During our introduction we discuss the options. What needs to be automated?

Concept design

Our engineers will start working on a concept design. You will receive this with a simulation, clear cost estimate and project description.

Kick-off meeting

If the concept is approved, we prepare a detailed requirements package, determine the project scope and deliverables. Once we agree on those, our engineers get to work on a final design.

Design review

For the design review, we test the design against the set requirements together with you in order to identify problems before any further work is committed.

Production

Once the concept has been approved, we get started on production. The design is realized in our manufacturing facility.

Factory Acceptance Test

During the FAT, we validate the performance of the equipment and ensure that it meets all requirements.

On-site installation

Our engineers install the system on site.

Site Acceptence Test

We verify that the system is working properly and that integration with other systems and networks in your production facility is smooth.

Training

After the SAT, we provide training to the operators so that they can handle the new system well.

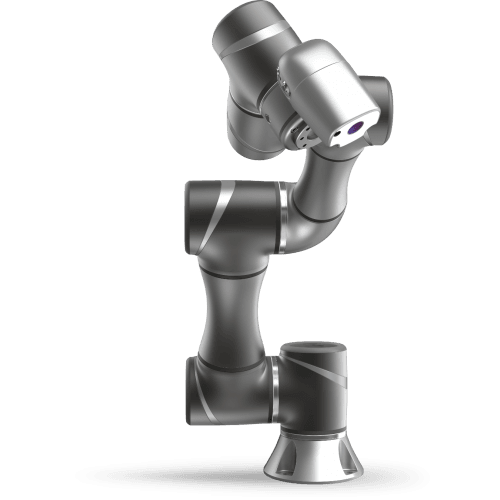

Mechanical engineering with cobots

We specialize in automation with collaborative robots (cobots). Versatile, cost-effective and easy to use. This makes them suitable for companies of almost any size and any level of technical expertise.

The benefits of automation

Reduces operating costs

Thanks to automation, personnel costs are reduced.

Increased productivity

Employees can do important work elsewhere, which increases production.

Higher quality

Automation reduces the margin of error, which results in higher quality. In addition, it results in products of uniform quality.

Higher flexibility

Robots can be programmed to perform any task. This makes the production process more flexible.

Safety

Automation can make the production line safe for workers by using robots to do dangerous tasks.

Get to know us!

Our combination of a multidisciplinary team with years of experience, knowledge in the field of automation, a wide selection of robots and extensive tooling means that we can provide a solution to virtually any problem from design to realization. We always communicate honestly about what we do, what we can do and what the costs are.