Increase productivity

Automate repetitive tasks with the Cobot Case Erector, allowing your packaging line to work faster and more efficiently.

Reduce costs

Reduce labor costs by using a cobot, which requires less human supervision and works more accurately.

Improve efficiency

Case

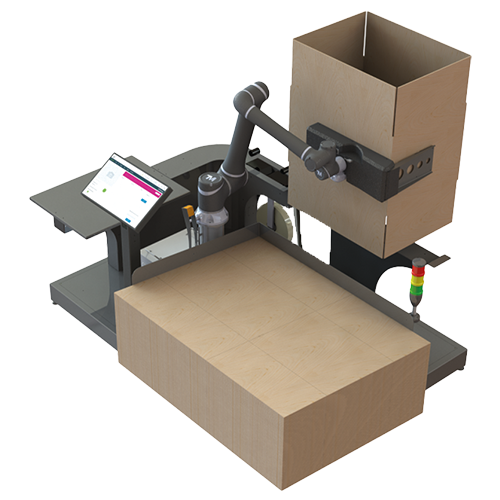

In house developed Cobot Case Erector

The Cobot Case Erector is an in-house developed Plug & Produce solution that fits perfectly into a packaging line. Because of its standardised design, it can be quickly deployed with minor adjustments to your facility. In addition, it is portable and can be used in multiple locations. Thanks to the user-friendly software, you can program new box formats quickly and easily.

Technical specifications

- Weight

+- 350 KG

- Boxes per minute

2 to 3 boxes

- Minimum box size

200 x 300 x 100 mm

- Maximum box size

800 x 600 x 500 mm

Frequently asked questions

How easy is it to install and integrate the Cobot Case Erector into our existing packaging line?

Installation of the cobot case erector is quick and easy, and can usually be completed within one day. Thanks to its modular design and compatibility with various systems, it can be easily integrated into your existing packaging line without extensive modifications.

What types and sizes of boxes can be processed by the cobot?

What are the maintenance requirements for the Cobot Case Erector?

How safe is the cobot box erector for use in a work environment with employees?

What is the payback period (ROI) of the Cobot Case Erector?

Do you still have questions?

Book an online consultation with our cobot specialist and get all your questions answered.