Why choose a cobot palletizer?

Increased efficiency

Automate repetitive tasks and save time, making your production line run faster and more efficiently.

Reduce costs

Reduce operational costs by reducing manual labor .

Safety

Designed to work safely with people, minimizes risk and increases workplace safety.

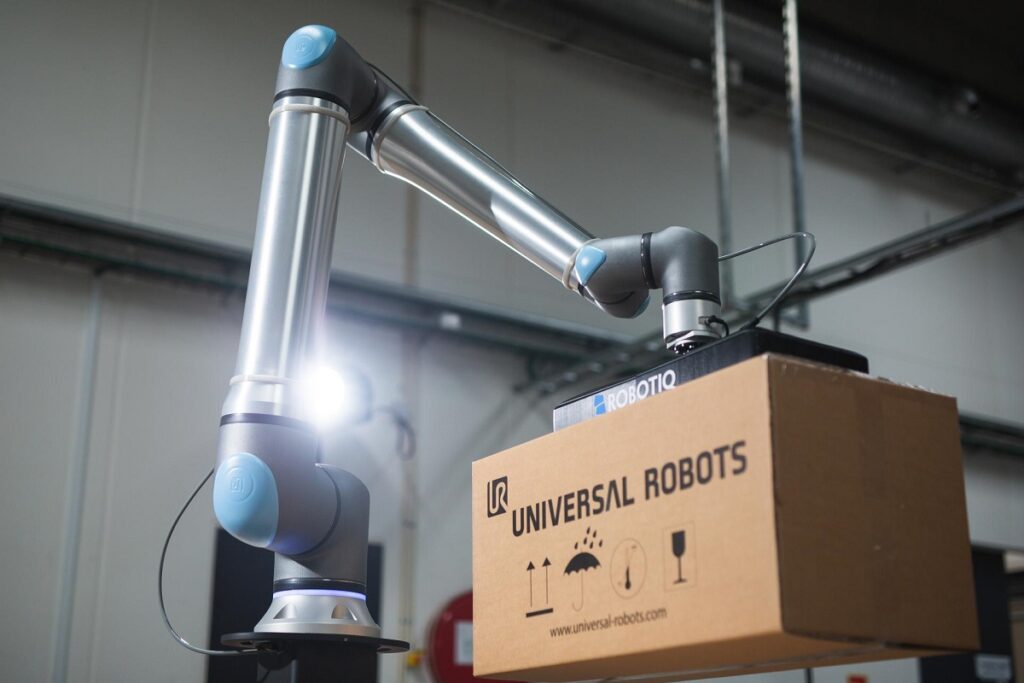

In-house developed palletizer

The cobot palletizer is an internally developed plug & produce solution that can be seamlessly integrated into your packaging line. Its standardized design allows for quick deployment with minimal line adjustments, and it is highly mobile so it can be used in multiple locations. With its user-friendly software, programming new pallet patterns is quick and easy.

Technical specifications

- Weight

+- 200 kg

- Max. payload

25 kg

- Max. boxes per minute

3 to 4

- Max stack height

3 meter

- Power requirement

100 - 240 VAC

Cost savings and improved working conditions at Boermarke

For Boermarke, we developed an automatic palletizer equipped with a Fanuc robot and gripper that can pick up all kinds of box variations.

Frequently Asked Questions

What are the main advantages of palletizing with a cobot?

Palletizing with a cobot offers several benefits, including cost savings through reduced personnel costs, increased productivity by allowing workers to focus on more complex tasks, and consistent quality because robots always work the same way without loss of concentration. In addition, cobots help prevent physical injuries in workers by taking over repetitive and heavy tasks.

How fast can a cobot palletizer stack boxes?

Is a cobot palletizer easy to integrate into my existing production line?

What are important factors to consider when designing a palletizer layout?

What safety measures are needed to use a cobot palletizer?

Do you still have questions?

Book an online consultation with our cobot specialist and get all your questions answered.